Nimonic Alloy Temperature Shields with Precision 3D Printing for Superior Insulation

Introduction

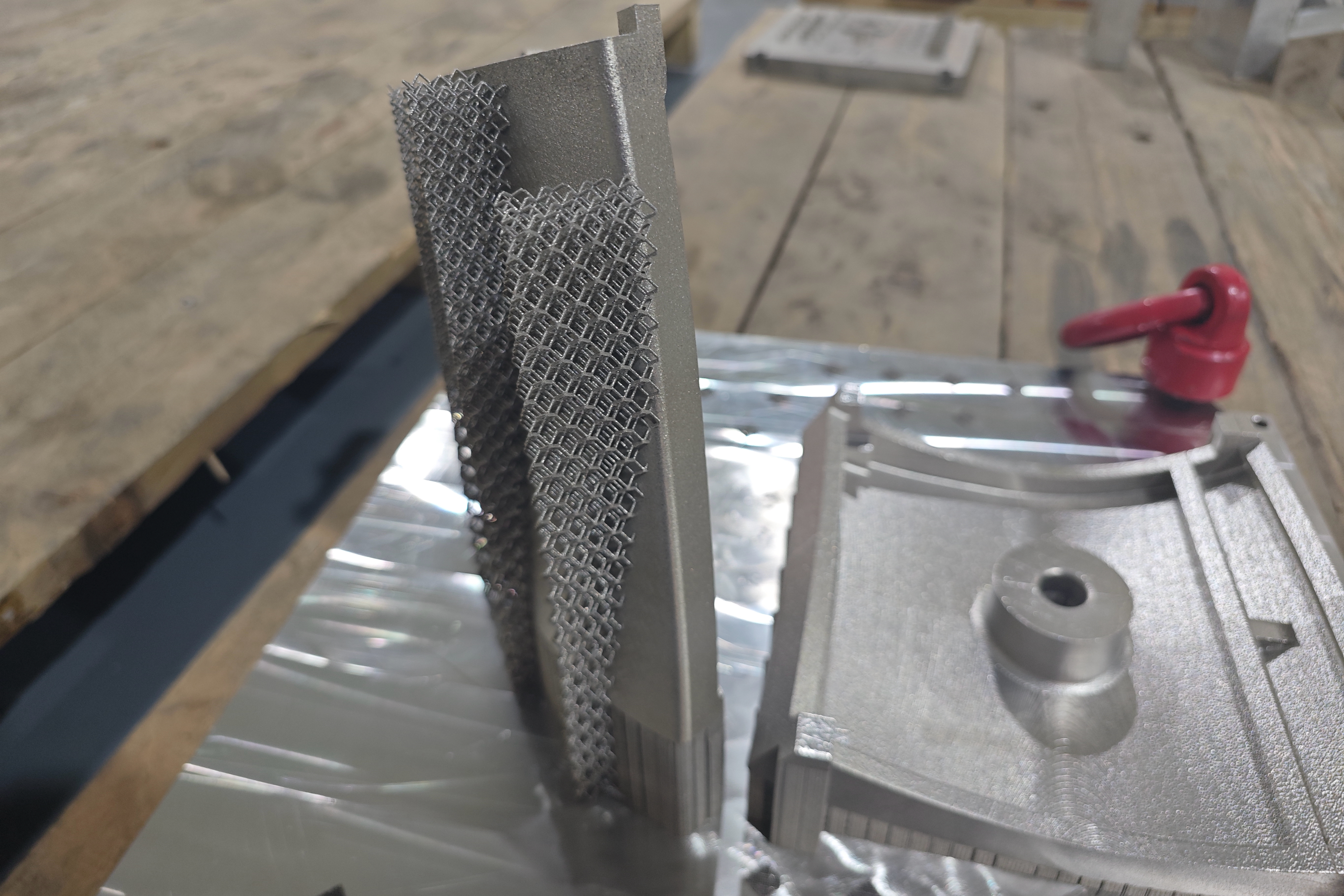

Nimonic alloys are engineered for outstanding high-temperature strength, oxidation resistance, and creep performance, making them ideal materials for advanced thermal insulation systems. At Neway AeroTech, we specialize in 3D printing services for Nimonic alloys, manufacturing lightweight, complex temperature shields designed for maximum thermal resistance and mechanical durability in aerospace, energy, and industrial applications.

Utilizing cutting-edge Selective Laser Melting (SLM) technology, Neway produces high-density, precision-engineered Nimonic thermal shields capable of continuous service under extreme heat loads.

Core Manufacturing Challenges for Nimonic Temperature Shields

Producing high-performance 3D printed temperature shields from Nimonic 90 and Nimonic 263 involves specific challenges:

Managing residual stress and minimizing warping during layer-by-layer solidification under high thermal gradients.

Achieving densities above 99.5% to ensure fatigue resistance, oxidation resistance, and mechanical integrity.

Maintaining tight dimensional tolerances (±0.05 mm) across complex geometries.

Achieving surface finishes Ra ≤5 µm necessary for minimizing thermal radiation losses and oxidation sites.

3D Printing Process for Nimonic Alloy Temperature Shields

The 3D printing process for Nimonic shields includes:

Powder Qualification: Gas-atomized Nimonic powders with particle sizes between 15–45 µm for consistent flowability and laser absorption.

Selective Laser Melting (SLM): Fusion under inert argon atmosphere to prevent oxidation, with optimized scan speeds (~700 mm/s) and laser powers (~300–400 W).

Process Optimization: Hatch spacing, laser overlap, and layer thickness (~30–50 µm) fine-tuned to achieve near-full density.

Support Removal and HIP Treatment: Support structures removed followed by Hot Isostatic Pressing (HIP) to close any residual micro-porosity.

Precision CNC Finishing: Achieving final tolerances (±0.01 mm) and smooth surfaces Ra ≤1.6 µm on sealing and mounting surfaces.

Heat Treatment: Stress-relieving, solution treatment, and aging to optimize strength, creep resistance, and thermal fatigue life.

Comparison of Manufacturing Methods for Nimonic Temperature Shields

Manufacturing Method | Dimensional Accuracy | Surface Finish (Ra) | Thermal Resistance | Mechanical Strength | Cost Efficiency |

|---|---|---|---|---|---|

3D Printing (SLM) | ±0.05 mm | ≤5 µm | Superior | Superior | Medium |

Vacuum Investment Casting | ±0.1 mm | ≤3.2 µm | Good | Good | Medium |

CNC Machining (from Solid) | ±0.01 mm | ≤0.8 µm | Excellent | Excellent | High |

Manufacturing Method Selection Strategy

Choosing the optimal manufacturing method depends on complexity, thermal load, and weight savings:

3D Printing (SLM): Ideal for ultra-lightweight, complex-shaped shields incorporating cooling channels or lattice structures for advanced heat dissipation while maintaining mechanical strength.

Vacuum Investment Casting: Suitable for simpler heat shields where moderate complexity and standard surface finish are acceptable.

CNC Machining (from Solid): Reserved for simpler geometries requiring extreme surface finishes (Ra ≤0.8 µm) and ultra-tight dimensional accuracy (±0.01 mm).

Nimonic Alloy Performance Matrix

Alloy Material | Max Service Temp (°C) | Tensile Strength (MPa) | Creep Resistance | Oxidation Resistance | Typical Applications |

|---|---|---|---|---|---|

950 | 1200 | Superior | Superior | Aerospace shields, turbine discs | |

870 | 930 | Excellent | Excellent | Combustion chamber shields | |

850 | 1050 | Good | Superior | Compressor thermal covers | |

750 | 820 | Moderate | Good | Industrial insulation systems | |

870 | 960 | Excellent | Excellent | Turbine hot section shields |

Alloy Selection Strategy for Temperature Shields

Material selection ensures optimal thermal performance:

Nimonic 90: Best for shielding components requiring maximum creep and fatigue resistance at high temperatures up to 950°C.

Nimonic 263: Ideal for complex structures needing toughness and oxidation resistance at service temperatures up to 870°C.

Nimonic 80A: Chosen for components exposed to moderate stresses and temperatures around 850°C with excellent oxidation resistance.

Nimonic 75: Cost-effective choice for industrial shields requiring moderate strength and oxidation protection.

Nimonic PE16: Applied where continuous exposure to elevated temperatures (~870°C) demands stable mechanical properties and thermal fatigue resistance.

Key Post-processing Techniques

Post-processing is critical to optimize mechanical and thermal performance:

Hot Isostatic Pressing (HIP): Densifies parts to >99.9%, improving fatigue and thermal cycling resistance.

Heat Treatment: Stress relief, solution treatment, and aging processes to optimize mechanical strength and phase stability.

Precision CNC Finishing: Achieves high-precision sealing surfaces and aerodynamic profiles.

Protective Surface Coatings: Application of oxidation-resistant coatings to extend service life.

Testing Methods and Quality Assurance

Neway AeroTech guarantees quality through stringent aerospace-grade testing:

Coordinate Measuring Machine (CMM): Dimensional verification with ±0.005 mm precision.

X-ray Non-destructive Testing: Internal defect analysis.

Metallographic Microscopy: Microstructure evaluation for grain uniformity and phase integrity.

Tensile Testing: Mechanical property validation for tensile strength, yield strength, and elongation.

All production processes comply with AS9100 aerospace quality standards.

Case Study: 3D Printed Nimonic 90 Aerospace Thermal Shields

Neway AeroTech delivered 3D printed Nimonic 90 temperature shields for aerospace turbine hot sections:

Service Temperature: Continuous operation at 950°C

Dimensional Precision: ±0.05 mm across intricate geometries

Surface Finish: Ra ≤4.5 µm achieved after finishing

Certification: Fully compliant with AS9100 aerospace quality management system

FAQs

Why are Nimonic alloys ideal for 3D printed thermal insulation shields?

What dimensional tolerances can Neway AeroTech achieve with 3D printed Nimonic parts?

How does Hot Isostatic Pressing (HIP) enhance 3D printed Nimonic components?

Which Nimonic grades are recommended for extreme-temperature shielding applications?

What quality certifications does Neway AeroTech follow for manufacturing thermal insulation shields?