What is the role of precision forging in reactor vessel component manufacturing?

Enhanced Material Integrity and Grain Flow

Precision forging plays a crucial role in reactor vessel manufacturing by creating a superior, continuous grain structure that closely follows the component's contour. Unlike machining from bar stock, which can cut through grain lines and create stress concentrations, the superalloy precision forging process refines the microstructure and aligns the grain flow to enhance mechanical properties. This results in exceptional resistance to creep, thermal fatigue, and neutron embrittlement—all vital for long-term reliability in the harsh environment of a nuclear reactor where component failure is not an option.

Superior Mechanical Properties for Critical Applications

The dynamic deformation during forging produces a uniform, fine-grained microstructure that significantly increases the toughness and tensile strength of the material compared to cast or fabricated alternatives. For large, critical nuclear components like reactor vessel flange connectors, control rod drive mechanism (CRDM) housings, and primary coolant system parts, this translates to a higher safety margin and proven performance under extreme pressure and temperature cycles. This level of integrity is essential for meeting the stringent certification standards of the nuclear industry.

Reduction of Defects and Improved Reliability

Forging consolidates the material, effectively eliminating internal voids, gas porosity, and shrinkage defects commonly associated with casting. This dense, homogeneous structure is far less susceptible to in-service crack initiation and propagation. When combined with post-process treatments like Hot Isostatic Pressing (HIP), forged components achieve near-theoretical density, providing the utmost confidence in their performance over a multi-decade service life.

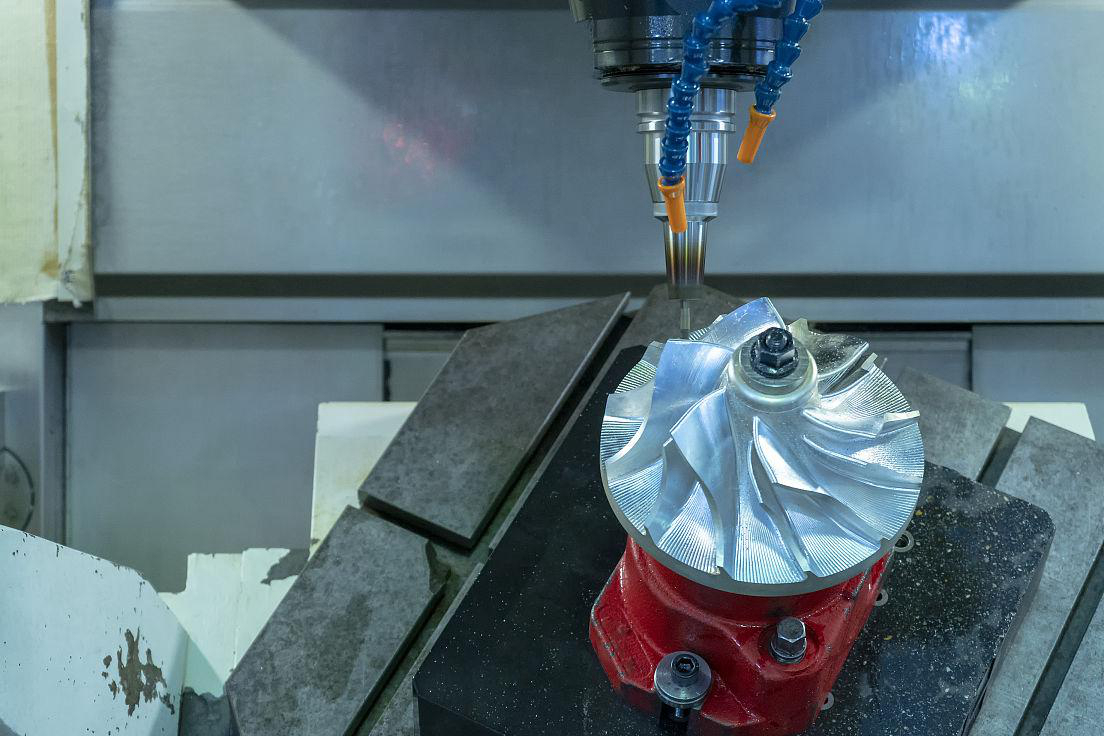

Near-Net-Shape Efficiency and Material Conservation

Precision forging is often a near-net-shape process, minimizing the amount of expensive, high-performance superalloy that must be removed by subsequent CNC machining. This is not only cost-effective but also conserves material for critical power generation applications. The process allows for the creation of complex geometries with integral features, reducing the need for multiple welds or assemblies, which are potential points of failure in a reactor pressure boundary.