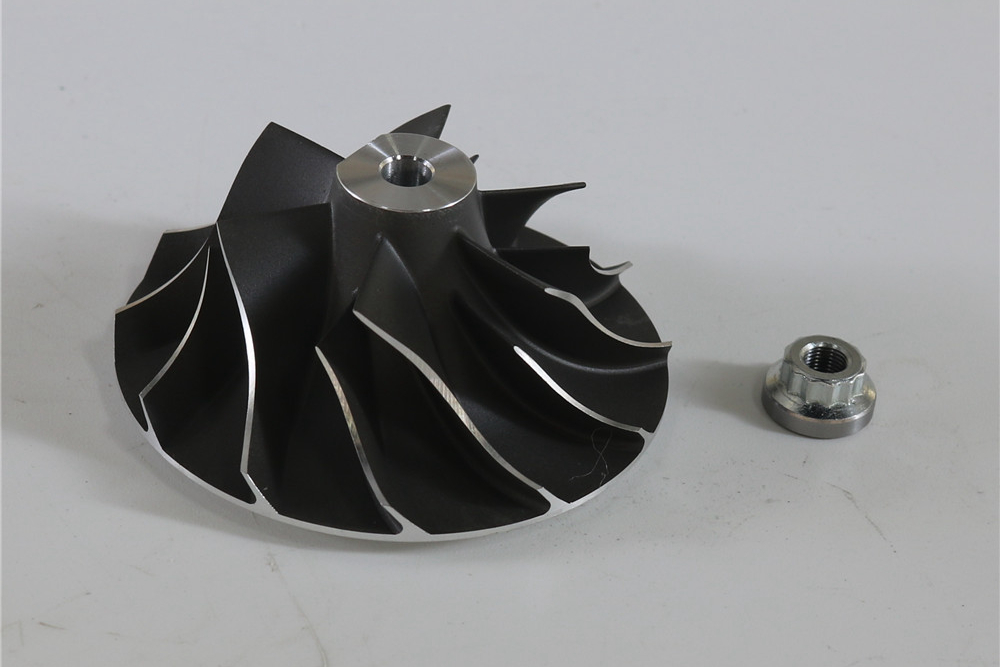

Automotive Turbocharger Components Rene Vacuum Investment Casting Foundry

Introduction to Rene Alloy Turbocharger Components

Automotive turbocharger components demand superior alloys to withstand extreme thermal conditions, rotational stresses, and fatigue loads. Neway AeroTech is a specialized Rene alloy vacuum investment casting foundry, expertly producing precision-cast turbocharger components designed specifically for high-performance automotive applications. Utilizing premium Rene alloys, including Rene 41 and Rene 80, we ensure unmatched durability, temperature resistance, and operational reliability.

Our industry-leading casting expertise positions us as a preferred supplier for demanding automotive turbocharger applications.

Key Manufacturing Challenges in Rene Alloy Casting

The complexity involved in vacuum investment casting of Rene alloy turbocharger components includes:

High-temperature Stability: Required operational stability above 950°C.

Dimensional Precision: Maintaining tolerance levels within ±0.15 mm for complex geometries.

Surface Integrity: Achieving uniform surface finishes (Ra 3.2–6.3 µm) to reduce aerodynamic losses.

Material Purity: Controlling alloy impurities below 0.01% under stringent vacuum conditions (<0.1 Pa).

Detailed Rene Alloy Vacuum Investment Casting Process

Wax Pattern Manufacturing

High-precision tooling generates wax patterns replicating complex turbocharger geometries accurately within ±0.1 mm tolerance.

Ceramic Shell Molding

Patterns are repeatedly coated with specialized ceramic slurry, building shell layers with thicknesses of 6–10 mm to handle molten Rene alloys (~1400°C).

Vacuum Melting and Casting

Rene alloys undergo vacuum induction melting in a controlled chamber environment (<0.1 Pa) to eliminate gas contamination.

Molten alloy is poured precisely into ceramic molds, producing near-net shapes.

Finishing Operations

Ceramic shells are removed mechanically or chemically.

CNC precision finishing ensures component accuracy of ±0.15 mm and surface quality of Ra 3.2–6.3 µm.

Comparison of Turbocharger Component Manufacturing Processes

Manufacturing Process | Precision | Surface Finish | Complexity Handling | Production Efficiency |

|---|---|---|---|---|

Vacuum Investment Casting | ±0.15 mm | Ra 3.2–6.3 µm | High | Moderate–High |

CNC Machining | ±0.005 mm | Ra 0.8–1.6 µm | Moderate | Moderate |

Selective Laser Melting (SLM) | ±0.10 mm | Ra 6.3–12.5 µm | High | Moderate |

Forging | ±0.2 mm | Ra 6.3–12.5 µm | Moderate | High |

Manufacturing Process Selection Strategy

Vacuum Investment Casting: Ideal for complex-shaped Rene alloy turbocharger parts demanding consistent dimensional accuracy (~±0.15 mm).

CNC Machining: Optimal for high-precision finishing applications where extremely tight tolerances (±0.005 mm) are required.

Selective Laser Melting (SLM): Suitable for rapid prototyping and production of parts with intricate internal cooling features.

Precision Forging: Effective for producing parts requiring high structural integrity at slightly reduced accuracy levels (±0.2 mm).

Rene Alloy Material Performance Matrix

Rene Alloy | Tensile Strength | Yield Strength | Max Temp | Fatigue Resistance | Automotive Application |

|---|---|---|---|---|---|

1240 MPa | 860 MPa | 980°C | Excellent | High-performance turbine wheels | |

1300 MPa | 850 MPa | 950°C | Superior | Turbocharger discs | |

1200 MPa | 840 MPa | 900°C | Exceptional | Exhaust turbine wheels | |

1450 MPa | 960 MPa | 870°C | Outstanding | High-load rotor components | |

1550 MPa | 1000 MPa | 850°C | Outstanding | Advanced turbine components | |

1300 MPa | 900 MPa | 1050°C | Superior | High-temperature turbine parts |

Rene Alloy Material Selection Strategy

Rene 41: Selected for turbocharger wheels operating at continuous temperatures approaching 980°C, ensuring excellent fatigue resistance.

Rene 80: Ideal for automotive discs requiring high-temperature strength and reliability at 950°C.

Rene 77: Chosen for turbine wheels requiring robust fatigue life at operating temperatures around 900°C.

Rene 88: Optimal for highly stressed rotor components needing superior mechanical strength (1450 MPa tensile) at 870°C.

Rene 142: Best suited for critical turbocharger components demanding ultimate strength (1550 MPa) at temperatures up to 850°C.

Rene N5: Ideal for turbine parts experiencing extreme heat conditions, reliably performing at temperatures up to 1050°C.

Key Post-processing Technologies

Heat Treatment: Maximizes mechanical properties and fatigue life of turbocharger components.

Hot Isostatic Pressing (HIP): Eliminates internal porosity, ensuring reliability and structural integrity.

Thermal Barrier Coating (TBC): Reduces heat exposure of components, prolonging lifespan and performance.

Dynamic Balancing: Minimizes vibration, ensuring reliable high-speed operation.

Industry Case Study: Precision Rene Alloy Turbocharger Components

Neway AeroTech recently completed a Rene 80 turbocharger disc project for a prominent automotive manufacturer. Using advanced vacuum investment casting, HIP treatment, and dynamic balancing, we achieved exceptional dimensional accuracy (±0.15 mm), high-temperature strength (1300 MPa), and outstanding fatigue resistance. These attributes substantially improved turbocharger performance, meeting stringent automotive industry standards.

Our comprehensive Rene alloy casting capabilities reaffirm our leadership in automotive turbocharger component manufacturing.

FAQs

What is your typical lead time for Rene alloy turbocharger components?

Can you produce prototypes or small production batches using vacuum investment casting?

Which automotive industry standards and certifications do your Rene alloy components meet?

Do you provide material selection guidance tailored for specific turbocharger applications?

What quality assurance methods do you use to validate the performance of cast Rene alloy parts?