Plastic

Material Introduction

Plastic for 3D printing encompasses a wide spectrum of thermoplastics and photopolymer resins engineered for rapid prototyping, functional validation, and end-use parts. From entry-level PLA to engineering-grade PEEK and nylon, these materials offer low density, good electrical insulation, and highly customizable mechanical behavior. Through a dedicated plastic 3D printing service, engineers can match materials with project requirements for stiffness, toughness, heat resistance, or flexibility. Neway’s integrated 3D printing service also supports general plastic 3D printing materials, making it possible to consolidate multi-component assemblies into single printed parts, reduce tooling investment, and accelerate design iterations. Plastics are especially attractive for housings, ergonomic handles, fixtures, ducting, fluidic components, and low-volume production, where speed and design freedom are more critical than extreme structural loads.

International Naming Table

Region / Standard | Common Naming / Designation Examples |

|---|---|

USA (ASTM / UL) | PLA, ABS, PETG, PC, PA12, TPU, PEEK |

Europe (EN / ISO) | ISO polymer grades (PA12, PC, PEEK, etc.) |

China (GB / QB) | General thermoplastics and engineering plastics to GB/T standards |

Japan (JIS) | JIS polymer grades such as ABS, PC, PA |

Global trade | Branded filaments and resins from major material suppliers |

Alternative Material Options

Although plastics cover a broad range of applications, some projects require higher strength, stiffness, or temperature capability. For lightweight structural components and heat-dissipating parts, aluminum 3D printing offers a good balance of strength, weight, and thermal conductivity. When corrosion resistance, hygiene, or pressure-bearing performance are essential, stainless steel 3D printing provides robust, cleanable parts. For extreme environments involving sustained high temperature, cyclic loading, or aggressive media, superalloy 3D printing is more appropriate. Within the polymer family itself, designers can upgrade from commodity thermoplastics to high-performance plastics such as PEEK or high-temperature nylons when long-term durability and elevated-temperature performance are required.

Design Intent of Plastics for 3D Printing

Plastics used in additive manufacturing are formulated to turn digital designs into physical parts quickly, economically, and reliably, without the need for traditional tooling. The primary design intent is to ensure printability, dimensional stability, and tailored performance. Base polymers, such as polylactic acid (PLA), are optimized for low warpage, good bed adhesion, and predictable shrinkage, making them ideal for concept models. Engineering filaments, such as acrylonitrile butadiene styrene (ABS) and polyethylene terephthalate glycol (PETG), are designed for impact strength and durability. Elastomeric thermoplastic polyurethane (TPU) is ideal for flexible parts, such as seals, gaskets, or soft-touch elements. High-end polycarbonate (PC) and polyether ether ketone (PEEK) grades are intended for structurally demanding and high-temperature applications. Resin systems, including photopolymer resins, are designed for ultra-fine detail and smooth surfaces in sectors like medical, dental, and consumer products.

Chemical Composition (Representative Thermoplastic System)

Component | Typical Content (wt%) |

|---|---|

Base polymer (PLA/ABS/PA/PC, etc.) | 85–98 |

Reinforcing fibers (glass/carbon) | 0–15 |

Impact modifiers / tougheners | 0–10 |

Colorants / pigments | 0–3 |

Stabilizers (UV / thermal) | 0–2 |

Processing aids / lubricants | 0–2 |

(Exact composition depends on the specific plastic family and grade.)

Physical Properties (Typical Ranges)

Property | Typical Range |

|---|---|

Density | 1.0–1.35 g/cm³ |

Heat Deflection Temperature | 55–150 °C |

Thermal Conductivity | 0.15–0.30 W/m·K |

Specific Heat | 1200–2000 J/kg·K |

Coefficient of Thermal Expansion | 60–120×10⁻⁶ /K |

Electrical Behavior | Generally insulating |

Mechanical Properties (Typical Ranges for Printed Plastics)

Property | Typical Range |

|---|---|

Tensile Strength | 35–90 MPa |

Tensile Modulus | 1.5–3.0 GPa |

Elongation at Break | 3–50% (brittle to ductile) |

Flexural Strength | 50–130 MPa |

Izod Impact Strength | 20–900 J/m (tough grades) |

Hardness | Shore D 70–85 / Shore A 80–95 |

Material Characteristics

Plastics for 3D printing are valued for their low density, design flexibility, and broad tunability of stiffness, toughness, and surface finish. Simple materials like PLA are easy to print, dimensionally stable, and well-suited for visual models. Engineering polymers, such as nylon (polyamide), provide excellent wear resistance, fatigue strength, and low friction for gears, bearings, and other moving mechanisms. High-performance plastics like PEEK can withstand long-term exposure to elevated temperature and aggressive chemicals, enabling metal-replacement designs.

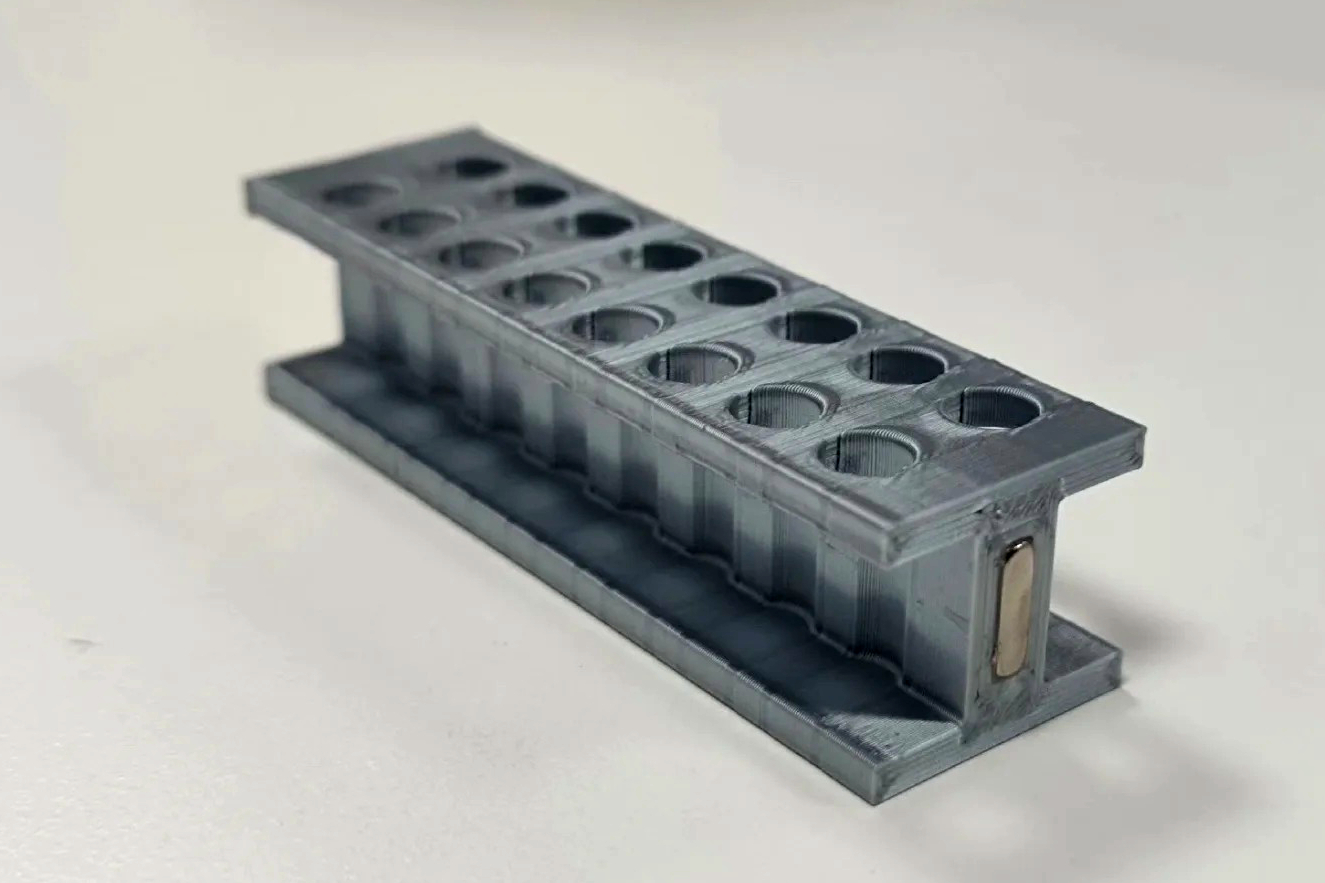

Plastics also offer integrated functionality: snap fits, living hinges, compliant mechanisms, seals, and cable routing can be built directly into a single printed part. Materials such as standard resin deliver smooth surfaces and detailed features, while tough resin and flexible resin support applications that require impact resistance and elasticity. Specialty plastics further extend performance to flame-retardant, ESD-safe, or chemically resistant grades. Overall, plastics provide a unique combination of lightweight design, functional integration, and rapid manufacturability that is difficult to match with metals alone.

Manufacturing Process Performance

Plastics are compatible with several 3D printing technologies, each tailored to specific performance and productivity needs. Filament-based FDM/FFF processes use materials such as PLA, ABS, polyethylene terephthalate glycol (PETG), polypropylene (PP), and conductive filament to produce robust prototypes and functional parts. Printing success depends on accurate temperature control, optimized support strategies, and careful management of cooling to reduce warpage and delamination.

Powder-based processes using nylon and related polymers, such as nylon (polyamide), offer near-isotropic mechanical behavior and high productivity, making them well-suited for series production, nested builds, and complex lattices. For metal-replacement or highly loaded components, carbon-fiber reinforced filament combines polymer processability with improved stiffness and dimensional stability.

Resin processes, including SLA and DLP, rely on photopolymer resins to deliver high resolution and excellent surface quality. Here, standard resin serves visual and general applications, while tough resin targets functional parts with better impact performance. Flexible resin provides elastomeric behavior for seals, pads, and soft-touch features. Across all processes, material selection, printer calibration, and parameter optimization are key to achieving consistent quality and predictable mechanical properties.

Applicable Post-processing Methods

Post-processing transforms printed plastic parts into finished components ready for testing or deployment. Standard operations include support removal, sanding, bead blasting, and polishing to improve surface appearance and tactile feel. Painting, dyeing, or coating can be used to match brand colors, improve UV stability, or increase chemical resistance for demanding environments.

Certain engineering polymers benefit from annealing to relieve residual stress and enhance dimensional stability. For parts produced using thermoplastics, threaded metal inserts, bushings, or over-molded features can be added to increase load-bearing capability at joints or interfaces. Resin-based parts typically require washing and post-curing to fully develop their mechanical performance and, where applicable, biocompatibility. With a well-designed post-processing workflow, plastic 3D prints can move from prototype aesthetics to durable, customer-ready assemblies.

Common Applications

Plastic 3D printing supports a wide range of applications, from concept models to fully functional end-use components. In the automotive sector, it is widely used for design studies, ergonomic evaluations, jigs, fixtures, and the creation of customized automotive components. Consumer electronics leverage printed plastics for housings, button assemblies, mounts, and wearable device components.

In regulated environments such as pharmaceuticals and food, plastics serve as non-contact fixtures, inspection tools, and protective covers. Within the broader energy sector, plastic parts are found in sensor holders, cable routing, control enclosures, and thermal or electrical insulation elements. Medical and dental industries rely on high-detail resin prints for anatomical models, surgical guides, and device evaluation. Across all these domains, plastics enable fast iteration, customization, and efficient low-volume manufacturing.

When to Choose Plastic for 3D Printing

Plastic is the material of choice when rapid iteration, cost efficiency, and design flexibility are primary objectives. It is ideal for early-stage concept models, ergonomic studies, and functional prototypes where geometry changes are frequent. Components that benefit from integrated hinges, snap fits, compliant sections, and complex internal channels are particularly well-suited to plastic AM because these features can be manufactured in one piece without tooling.

For low- to medium-volume production, plastic 3D printing can replace or delay the need for injection-mold tooling, reducing upfront investment and shortening the time-to-market. PLA is recommended for visual and proof-of-concept parts, while ABS, PETG, and PP are suitable for robust housings and fixtures. Nylon and PC are preferred for higher load and fatigue demands. TPU and flexible resins are suitable for elastomeric or impact-absorbing components, and high-performance plastics such as PEEK are recommended for high-temperature or chemically aggressive environments. When requirements exceed the thermal, mechanical, or long-term creep capabilities of polymers, designers should consider transitioning to metal or superalloy 3D printing. However, for the majority of prototypes and many end-use parts, plastics provide an excellent balance of performance, speed, and cost.