316L

Material Introduction

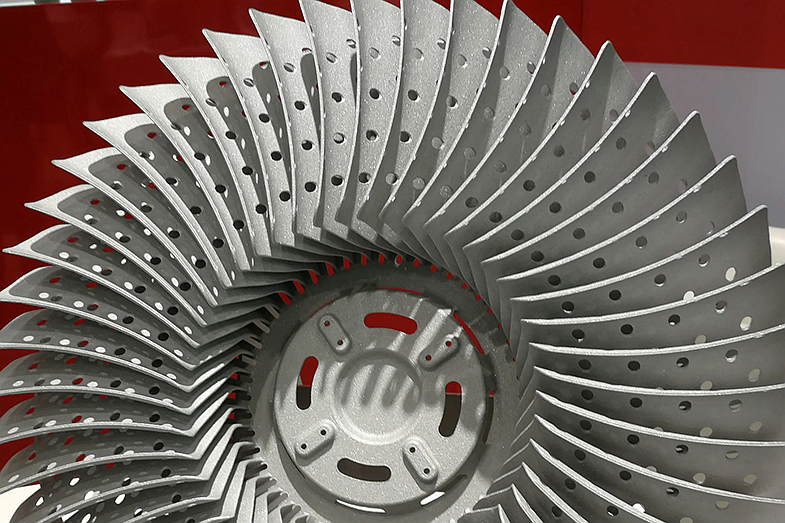

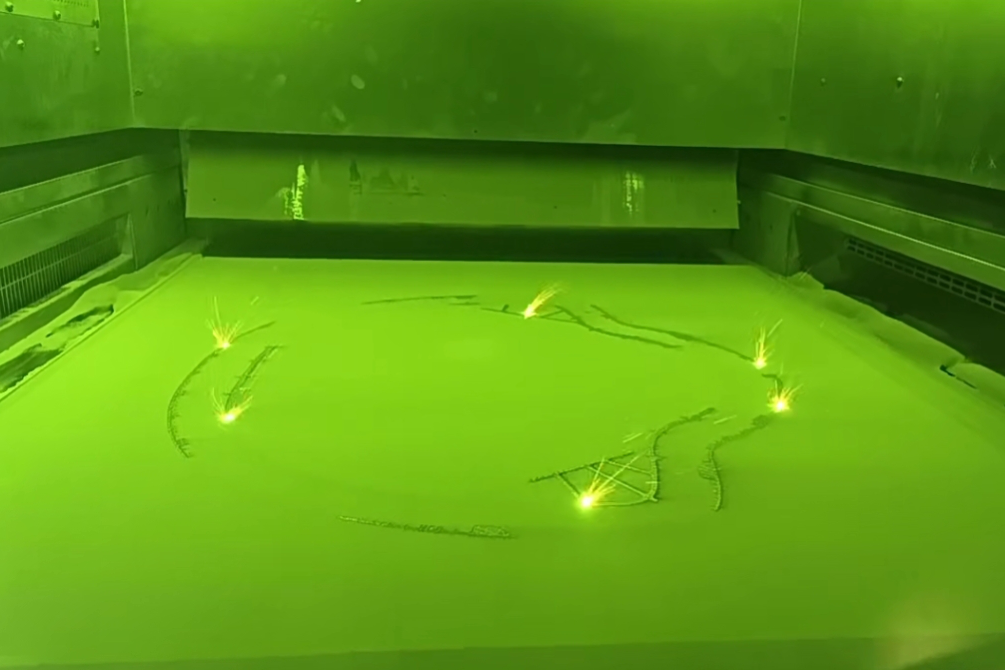

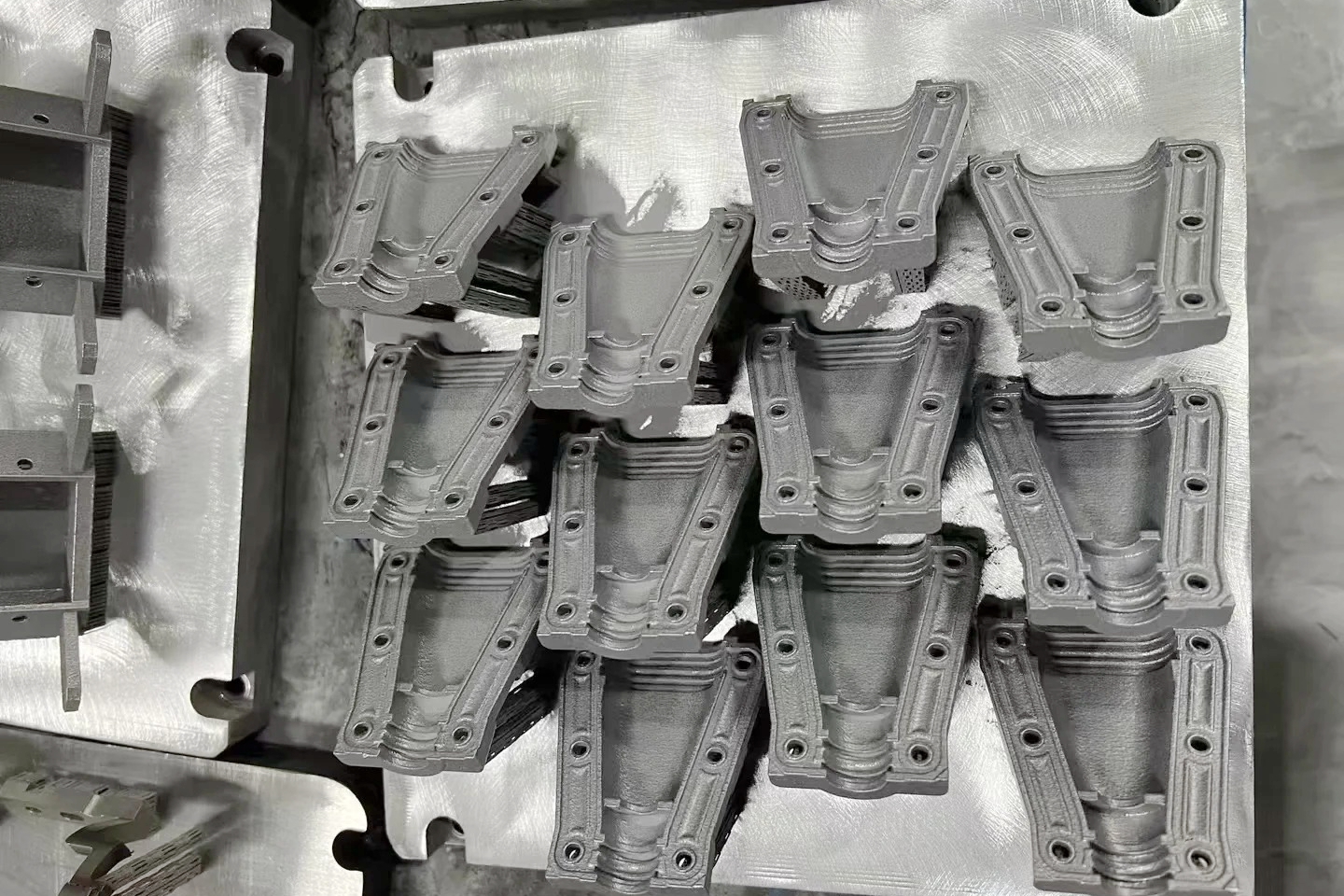

316L is an austenitic stainless steel known for its exceptional corrosion resistance, excellent ductility, and high toughness. In additive manufacturing, 316L has become one of the most widely used metals due to its stable melting behavior, strong mechanical performance, and ability to achieve fully dense parts with fine microstructures. Through stainless steel 3D printing, 316L components are produced with high dimensional accuracy and minimal porosity, making the material suitable for demanding applications in chemical processing, medical devices, marine structures, food equipment, and industrial machinery. Its low carbon content improves weldability and minimizes the risk of carbide precipitation, ensuring long-term corrosion resistance in harsh environments. With Neway’s advanced powder-bed fusion capabilities, 316L printed parts offer excellent performance for prototyping, functional components, and small-batch production.

International Naming Table

Region / Standard | Naming / Designation |

|---|---|

USA (ASTM) | 316L |

Europe (EN) | X2CrNiMo17-12-2 |

China (GB) | 022Cr17Ni12Mo2 |

Japan (JIS) | SUS316L |

Germany (DIN) | 1.4404 |

Alternative Material Options

Alternative stainless steels and alloys may be chosen depending on the required strength, corrosion environment, or temperature performance. For parts requiring higher strength, 17-4 PH stainless steel, available through 17-4 PH printing, provides superior hardness and tensile capabilities after aging treatment. For high-temperature and oxidation-resistant applications, nickel-based superalloys printed through superalloy 3D printing may be more suitable. If cost efficiency is a priority, 304 stainless steel produced via 3D printing offers similar corrosion resistance in mild environments. For tooling and die applications, tool steel provides higher hardness and wear resistance. These alternatives support engineers in balancing strength, corrosion performance, and manufacturing requirements.

Design Intent of 316L

316L was originally designed to deliver superior corrosion resistance in chloride-rich environments while maintaining excellent toughness and durability. Its low carbon content prevents carbide precipitation during welding, ensuring long-term resistance to intergranular corrosion. The addition of molybdenum enhances pitting and crevice corrosion resistance, especially in seawater, chemical processing equipment, and humid environments. With the growth of metal additive manufacturing, 316L became an ideal material for 3D printing due to its excellent weldability, stable thermal behavior, and ability to achieve near-full density with laser powder bed fusion. The design intent for 3D printing applications focuses on producing complex geometries, fine lattice structures, optimized cooling channels, and parts that require both structural integrity and corrosion resistance across various industrial environments.

Chemical Composition (wt%)

Element | wt% |

|---|---|

Cr | 16.0–18.0 |

Ni | 10.0–14.0 |

Mo | 2.0–3.0 |

Mn | ≤2.0 |

Si | ≤1.0 |

C | ≤0.03 |

P | ≤0.045 |

S | ≤0.03 |

Fe | Balance |

Physical Properties

Property | Value |

|---|---|

Density | 7.98 g/cm³ |

Melting Range | 1370–1400 °C |

Thermal Conductivity | 16 W/m·K |

Electrical Resistivity | 74 μΩ·cm |

Elastic Modulus | 193 GPa |

Coefficient of Thermal Expansion | 16×10⁻⁶ /K |

Mechanical Properties (AM + Heat Treated)

Property | Value |

|---|---|

Ultimate Tensile Strength | 550–650 MPa |

Yield Strength | 450–500 MPa |

Elongation | 35–45% |

Hardness | 150–200 HV |

Fatigue Strength | Moderate to high |

Impact Toughness | Excellent |

Material Characteristics

316L stainless steel offers excellent corrosion resistance, making it ideal for components exposed to seawater, acidic environments, and chemical processing. Its austenitic microstructure ensures outstanding ductility and toughness, even at low temperatures. The alloy exhibits exceptional weldability and maintains structural integrity after repeated thermal cycles, reducing the risk of cracking and distortion. In 3D printing, 316L’s fine microstructures enhance strength, provide uniform mechanical properties, and ensure minimal porosity. The alloy is highly resistant to pitting, crevice corrosion, and general corrosion, making it a preferred material for marine, food-processing, pharmaceutical, and medical applications. Its combination of hardness, ductility, and corrosion resistance allows it to operate reliably in conditions where other stainless steels may fail. Printed 316L also exhibits excellent surface quality, supporting intricate designs, thin walls, lattice structures, and lightweight geometries without sacrificing durability.

Manufacturing Process Performance

316L performs exceptionally well in metal additive manufacturing due to its stable melt pool behavior, good thermal conductivity, and ability to withstand rapid solidification. Powder-bed fusion produces dense, high-quality components with consistent microstructures and excellent mechanical performance. Heat treatment further homogenizes the microstructure and improves stress-relief properties. In addition to additive manufacturing, 316L is compatible with vacuum investment casting for complex shapes, but additive manufacturing offers better dimensional accuracy for intricate geometries. Machining is relatively straightforward due to the alloy’s toughness and ductility, though tool wear must be managed. For precision finishing operations, superalloy CNC machining can be utilized to achieve extremely tight tolerances. For deep internal channels or tube structures, deep hole drilling is an effective solution. Electrical discharge machining (EDM) is useful for achieving sharp transitions or complex internal cavities. 316L’s strong weldability supports hybrid manufacturing, enabling printed parts to be seamlessly integrated into larger assemblies without compromising corrosion resistance.

Applicable Post-processing

Stress-relief heat treatment is commonly applied to stabilize microstructures and reduce internal stresses. HIP performed via Hot Isostatic Pressing significantly improves density and fatigue resistance. Surface treatments, such as electropolishing, passivation, machining, and shot peening, enhance both surface finish and corrosion performance. Quality verification through material testing and analysis ensures dimensional accuracy, corrosion resistance, and compliance with food-grade or medical-grade standards when required.

Common Applications

316L is widely used in chemical processing equipment, corrosion-resistant housings, piping components, heat exchangers, valves, brackets, and structural assemblies requiring long-term durability. In marine environments, it is used for components exposed to seawater due to its strong resistance to chloride attack. The alloy is also prevalent in the medical industry for surgical tools, orthopedic components, and custom implants, leveraging the cleanliness and precision achievable through additive manufacturing. In industrial automation, robotics, and food processing equipment, 316L stainless steel offers excellent hygiene, corrosion resistance, and wear tolerance. Beyond industrial applications, 3D-printed 316L stainless steel is used in high-end consumer products, custom mechanical parts, jewelry, and functional prototypes that require a combination of aesthetic appeal and mechanical robustness.

When to Choose 316L

Select 316L when corrosion resistance is a primary requirement, particularly in environments with high chloride content, acidity, or humidity. It is ideal for components requiring a combination of toughness, ductility, and structural reliability. 316L is the preferred material when fabricating parts that must withstand harsh chemicals, seawater exposure, or stringent hygiene conditions. Select 316L for complex geometries that benefit from 3D printing, including lattice structures, cooling channels, thin-walled housings, and customized functional components. When weldability is essential or when hybrid manufacturing is required, 316L performs exceptionally well. However, if very high strength or high-temperature performance is required, alternatives such as nickel superalloys or precipitation-hardened stainless steels may be more appropriate.