Automotive Turbine Wheels Nimonic CNC Machining Company

Introduction to Nimonic Turbine Wheel CNC Machining

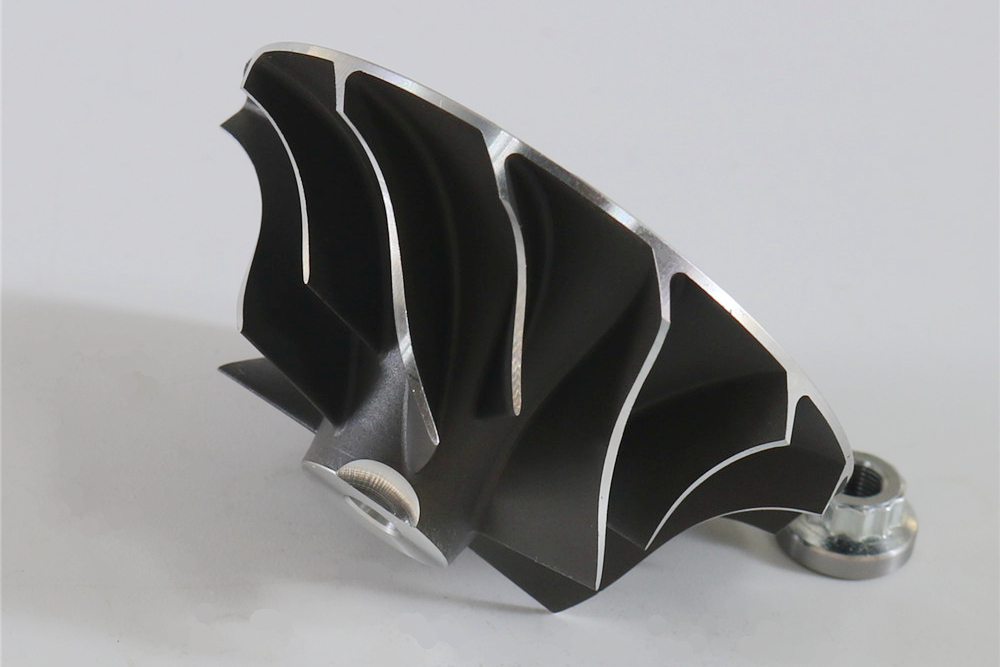

Automotive turbine wheels must operate under severe thermal and mechanical conditions, demanding exceptional strength, thermal stability, and fatigue resistance. Neway AeroTech, a leading Nimonic CNC machining company, specializes in the precision manufacturing of high-performance automotive turbine wheels. Using advanced nickel-based superalloys like Nimonic 90, we produce turbine wheels tailored specifically for demanding automotive turbocharging systems.

Our commitment to precision and quality positions us as a trusted partner in the automotive industry.

Key Challenges in Machining Nimonic Turbine Wheels

Machining turbine wheels from Nimonic alloys involves significant technical challenges:

High-Temperature Strength: Must maintain integrity at continuous temperatures exceeding 900°C.

Dimensional Precision: Tolerances within ±0.005 mm to achieve optimal aerodynamic efficiency.

Fatigue and Creep Resistance: Essential for sustained reliability under rotational speeds exceeding 150,000 RPM.

Machinability: Nimonic alloys exhibit low machinability (~20% relative to stainless steel), requiring specialized tooling.

CNC Machining Process for Nimonic Turbine Wheels

CNC Turning and Milling

Multi-axis CNC milling precisely shapes turbine blades and wheel geometries.

High-speed CNC turning achieves tight concentricity and dimensional accuracy.

Specialized carbide cutting tools and optimized machining parameters manage Nimonic's high strength and low thermal conductivity (~11 W/m·K).

Electrical Discharge Machining (EDM)

Wire EDM creates intricate blade profiles with superior dimensional accuracy (±0.002 mm).

Offers precise internal geometry, impossible to achieve through traditional machining.

Reduces residual stress and ensures component integrity.

Comparison of Wheel Manufacturing Methods

Method | Accuracy | Surface Finish | Production Efficiency | Complexity Handling |

|---|---|---|---|---|

CNC Turning/Milling | ±0.005 mm | Ra 0.8–1.6 µm | High | Moderate–High |

Wire EDM | ±0.002 mm | Ra 0.4–0.8 µm | Moderate | Very High |

Vacuum Investment Casting | ±0.15 mm | Ra 3.2–6.3 µm | Moderate–High | High |

Selective Laser Melting (SLM) | ±0.10 mm | Ra 6.3–12.5 µm | Moderate | High |

Manufacturing Process Selection Strategy

CNC Turning and Milling: Ideal for achieving tight tolerances (±0.005 mm) and repeatable accuracy for high-volume automotive turbine wheels.

Electrical Discharge Machining (EDM): Optimal for intricate turbine wheel profiles with stringent precision demands (±0.002 mm).

Vacuum Investment Casting: Suitable for cost-effective complex turbine shapes at moderate precision (±0.15 mm).

Selective Laser Melting (SLM): Effective for rapid prototyping and custom internal cooling channels.

Nimonic Material Performance Matrix

Material | Tensile Strength | Yield Strength | Max Temp | Fatigue Resistance | Automotive Applications |

|---|---|---|---|---|---|

1200 MPa | 760 MPa | 900°C | Superior | Turbocharger wheels | |

1400 MPa | 950 MPa | 850°C | Exceptional | High-performance wheels | |

1000 MPa | 585 MPa | 850°C | Excellent | Turbine blade segments | |

1250 MPa | 850 MPa | 850°C | Outstanding | Advanced turbine wheels | |

1150 MPa | 700 MPa | 815°C | Excellent | Medium-load turbine wheels | |

1120 MPa | 750 MPa | 750°C | Very Good | High-stress wheel applications |

Material Selection Strategy

Nimonic 90: Ideal for wheels operating continuously at 900°C, requiring excellent fatigue and creep resistance.

Nimonic 105: Recommended for ultra-high-performance turbine wheels demanding ultimate strength (1400 MPa tensile).

Nimonic 263: Suitable for parts requiring excellent thermal stability and good strength at temperatures around 850°C.

Nimonic 115: Selected for advanced turbine wheel applications needing robust strength (1250 MPa tensile) and reliability.

Nimonic 80A: Chosen for medium-load automotive turbine wheels due to balanced strength (1150 MPa) and durability at moderate temperatures (815°C).

Nimonic PE16: Appropriate for turbine wheels facing high cyclic stress, providing stable performance up to 750°C.

Key Post-processing Technologies

Heat Treatment: Enhances mechanical properties and significantly improves fatigue performance.

Hot Isostatic Pressing (HIP): Eliminates internal defects, increasing turbine wheel reliability and longevity.

Thermal Barrier Coating (TBC): Reduces operational temperatures by ~200°C, substantially extending component lifespan.

Dynamic Balancing: Minimizes vibration and ensures optimal wheel performance at rotational speeds above 150,000 RPM.

Industry Case Study: Precision Machined Nimonic Turbine Wheels

Neway AeroTech recently produced CNC-machined Nimonic 90 turbine wheels for a prominent automotive turbocharger manufacturer. Using advanced multi-axis CNC milling, EDM techniques, and comprehensive post-processing (heat treatment, HIP, and dynamic balancing), our turbine wheels met stringent dimensional accuracy standards (±0.005 mm) and demonstrated exceptional thermal stability, high fatigue life, and robust mechanical strength. These attributes significantly enhanced turbocharger efficiency and durability, exceeding client expectations.

Our specialized expertise and commitment to precision machining establish us as a leading Nimonic turbine wheel manufacturer.

FAQs

What is your typical production timeline for CNC-machined Nimonic turbine wheels?

Do you offer prototyping and small-batch production for automotive turbine wheels?

Which automotive and aerospace certifications do your turbine wheels comply with?

Can your technical team assist in selecting the optimal Nimonic alloy for specific turbocharger applications?

What quality control and testing methods do you use to ensure turbine wheel performance?