एयरोस्पेस घटकों की रफ फोर्जिंग में कौन-सी सुपरएलॉयज़ सबसे अधिक उपयोग होती हैं?

सामग्री तालिका

Performance Requirements for Rough-Forged Aerospace Components

Commonly Used Superalloys for Rough Forging

Processing and Post-Treatment Considerations

हिन्दी / HI

शीर्षक

एयरोस्पेस घटकों की रफ फोर्जिंग में कौन-सी सुपरएलॉयज़ सबसे अधिक उपयोग होती हैं?

विवरण

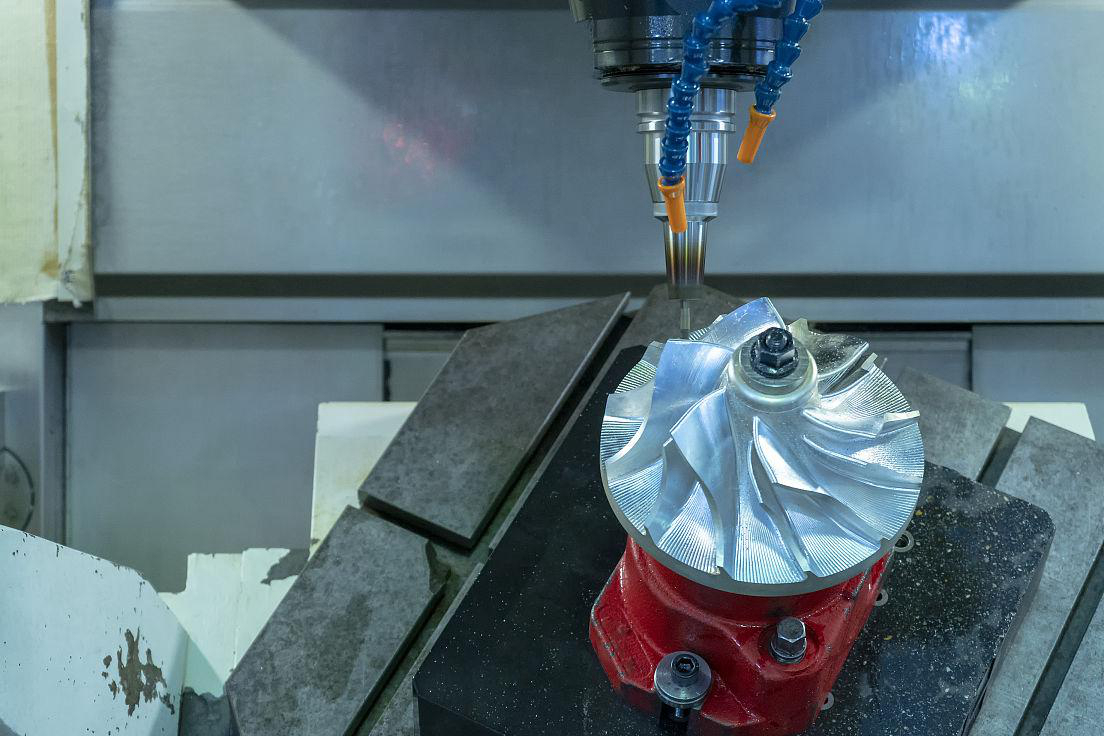

एयरोस्पेस रफ फोर्जिंग में मुख्यतः Inconel 718, Inconel 713LC और Stellite 6 उपयोग होती हैं, क्योंकि इनमें बेहतर हॉट वर्केबिलिटी, थर्मल रेसिस्टेंस और पोस्ट-प्रोसेसिंग उपयुक्तता होती है।

कीवर्ड्स

एयरोस्पेस रफ फोर्जिंग सुपरएलॉयज़, Inconel 718 बिलेट निर्माण, Inconel 713LC फोर्जिंग, Stellite 6 पहनाव भाग, प्रिसिजन फोर्जिंग तैयारी, HIP पोस्ट-ट्रीटमेंट एयरोस्पेस, सुपरएलॉय हीट ट्रीटमेंट, ग्रेन कंट्रोल फोर्जिंग सामग्री

Related Blogs

विशेषज्ञ डिजाइन और निर्माण की युक्तियाँ सीधे आपके इनबॉक्स में प्राप्त करने के लिए सदस्यता लें।

इस पोस्ट को साझा करें:

सेवाएँ

समाधान

Copyright © 2026 Aero Precision Works Ltd.All Rights Reserved.