Inconel Alloy Turbine Blades Superalloy Directional Casting Factory

Introduction to Inconel Turbine Blades with Directional Casting

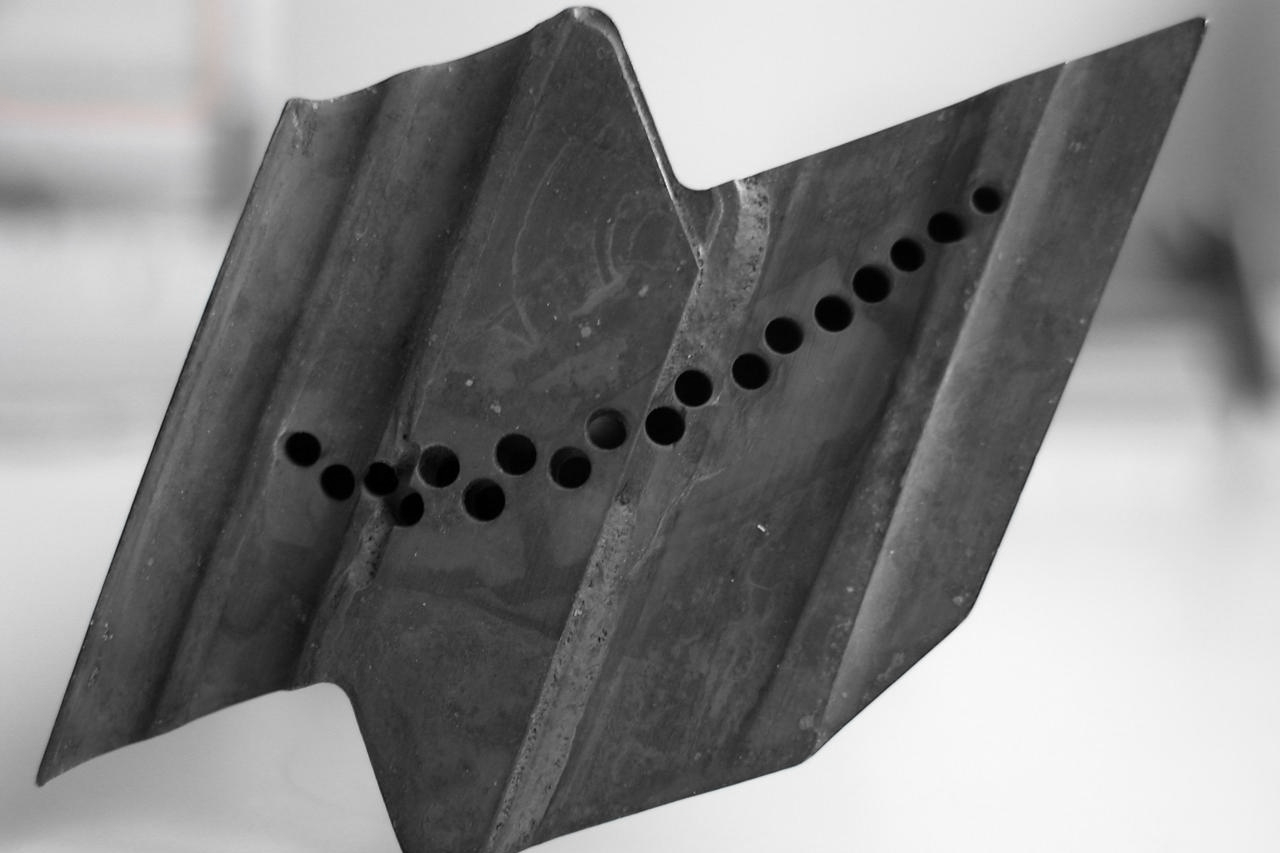

Turbine blades manufactured using directional solidification casting offer superior mechanical performance in high-temperature environments. Neway AeroTech is a leading factory for Inconel alloy turbine blades, producing precision components using directional casting technology to create aligned grain structures that significantly improve creep resistance, fatigue life, and thermal stability.

Our advanced foundry processes support aerospace, energy, and industrial turbine manufacturers with high-performance Inconel blades tailored for hot-section applications.

Why Directional Casting for Inconel Turbine Blades?

Directional casting solidifies the blade from the bottom up under controlled thermal gradients, producing aligned columnar grains. This enhances mechanical properties compared to equiaxed casting by:

Improving Creep Strength: Grain boundaries aligned parallel to the stress direction reduce deformation under high temperatures.

Increasing Fatigue Life: Eliminating transverse grain boundaries mitigates crack initiation and propagation.

Enhancing Thermal Fatigue Resistance: Columnar grains withstand cyclic thermal stress more effectively.

Key Casting Challenges and Solutions

Challenge | Our Solution |

|---|---|

Grain misalignment | Precision thermal gradient control (3–6°C/mm) and mold withdrawal rates |

Porosity and shrinkage | Hot Isostatic Pressing (HIP) to eliminate internal voids |

Dimensional tolerance (±0.10 mm) | Accurate wax pattern and ceramic mold design with CNC finishing |

Oxidation and contamination | Vacuum induction melting at <0.1 Pa to ensure clean castings |

Inconel Alloys Offered for Directional Casting

Alloy | Tensile Strength | Max Temp | Grain Type | Application |

|---|---|---|---|---|

1000 MPa | 980°C | Directional | Power turbine blades and vanes | |

1240 MPa | 980°C | Directional | Gas turbine airfoils | |

1250 MPa | 980°C | Directional | Turbine nozzles and blades | |

1350 MPa | 1000°C | Directional | Heavy-duty industrial turbine blades | |

1250 MPa | 1050°C | Directional | Turbine blades, discs |

Directional Casting Process Overview

Wax Pattern Creation

High-precision wax models formed with ±0.05 mm accuracy.

Ceramic Shell Formation

Mold built with multi-layer slurry (8–12 mm), capable of handling >1400°C molten Inconel alloys.

Vacuum Melting and Directional Solidification

Inconel alloy melted in vacuum at <0.1 Pa.

Mold withdrawn through thermal gradient zone (~3–6°C/mm) at controlled speed to promote directional grain growth.

Post-Casting Operations

Shell removal and CNC machining for root and tip features.

HIP treatment eliminates porosity.

Heat treatment optimizes mechanical properties.

Final NDT inspection for internal defects and grain verification.

Advantages of Directionally Cast Inconel Blades

2–3× longer creep life than equiaxed blades

Superior performance at 950–1050°C sustained operation

Enhanced reliability under cyclic load and thermal shock

Compatible with thermal barrier coatings (TBC) for further thermal protection

Example Application: Inconel 738 Directional Blades for Gas Turbines

Neway AeroTech recently delivered Inconel 738 directional cast turbine blades for a commercial gas turbine project. Blades were cast with columnar grain structure, HIP-treated, and CNC-finished to ±0.08 mm tolerance. Field tests confirmed a 40% increase in creep life and reduced thermal fatigue failure over 5,000-hour test cycles.

FAQs

What is the maximum blade size you can directional cast in Inconel alloys?

Do you offer HIP and heat treatment services for directional cast blades?

Can you produce prototype and low-volume batches for Inconel turbine blades?

What inspection methods do you use to verify directional grain structure?

What is the typical lead time for directional cast turbine blade orders?