Cobalt Alloys Nuclear Parts Special Alloy Casting Supplier

Introduction to Cobalt Alloy Nuclear Component Casting

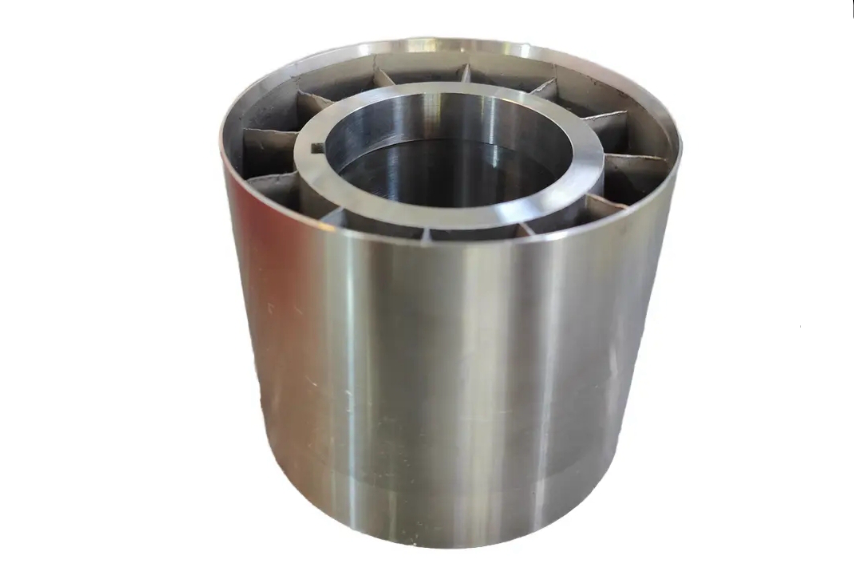

Cobalt-based alloys are widely used in the nuclear power industry due to their excellent wear resistance, corrosion resistance, and thermal stability under radiation and high-temperature conditions. Neway AeroTech is a specialized special alloy casting supplier offering precision cobalt alloy nuclear parts using vacuum investment casting. We manufacture critical components such as valve seats, pump wear rings, control rod guide tubes, and bearing surfaces using proven cobalt-based materials like Stellite 6, Stellite 21, and Stellite 25.

Our castings meet stringent nuclear-grade standards and are used in reactor internals, core support systems, and auxiliary nuclear equipment.

Advantages of Cobalt Alloys for Nuclear Applications

Radiation Stability: Cobalt alloys maintain mechanical properties under neutron irradiation with minimal embrittlement.

Wear Resistance: Ideal for sliding and rotating contact surfaces in control rod drives and valve components.

Corrosion Resistance: Withstand aggressive environments including borated water, steam, and high-pressure coolants.

Thermal Stability: Retain strength and toughness at temperatures exceeding 500°C.

Common Cobalt-Based Alloys We Cast

Alloy | Hardness (HRC) | Tensile Strength | Max Temp | Key Properties | Typical Nuclear Applications |

|---|---|---|---|---|---|

43–45 | ~860 MPa | 850°C | Wear and corrosion resistant | Valve seats, bushings, pump sleeves | |

35–40 | ~730 MPa | 850°C | Tough, corrosion-resistant | Control rod guide sleeves, valves | |

20–35 | ~930 MPa | 980°C | Excellent toughness, low wear | Reactor internals, bolting hardware | |

51–55 | ~960 MPa | 750°C | Extreme wear resistance | Hardfacing rings, bearing surfaces |

Precision Casting Process for Cobalt Alloy Nuclear Components

Wax Pattern Creation

Injection-molded wax models produced to ±0.05 mm accuracy for complex valve, guide, and seal components.

Ceramic Shell Molding

Multi-layer ceramic shell (8–12 mm) built around the pattern for vacuum casting of cobalt alloys at ~1450°C.

Vacuum Induction Melting & Casting

Alloy melted under vacuum (<0.1 Pa) and poured under inert conditions to avoid oxidation or gas porosity.

Post-Casting Processes

Shell removal, CNC finishing, HIP for porosity removal, and heat treatment as required.

Inspection & Certification

Non-Destructive Testing (NDT) including X-ray, ultrasonic, and dye penetrant testing for structural integrity and compliance with nuclear-grade standards.

Typical Cobalt Alloy Nuclear Components We Supply

Valve seats and discs for reactor coolant systems

Control rod drive sleeves and guide bushings

Pump wear rings and shaft sleeves

Reactor pressure vessel seals

Core support wear pads and brackets

Instrumentation support fixtures

Case Study: Stellite 6 Valve Seats for Nuclear Steam Supply System

Neway AeroTech supplied precision-cast Stellite 6 valve seats for a pressurized water reactor (PWR) primary loop. Components were vacuum cast, HIP-treated, and CNC-finished to ±0.10 mm. Testing confirmed excellent wear resistance in borated water environments and prolonged service life compared to previously forged versions. The client reported improved maintenance intervals and reduced downtime.

FAQs

What cobalt alloys do you supply for nuclear-grade components?

Can you meet ASME or ASTM nuclear material specifications?

Do you offer small-batch casting for replacement nuclear parts?

What inspection and testing procedures do you use for nuclear certification?

Can you assist with material selection and design optimization for Stellite components?