Superalloy Long Hole Drilled Components Electrical Discharge Machining

Precision Machining for Deep Internal Features

As aerospace and energy systems become more compact and efficient, the demand for complex internal geometries in superalloy components has increased. Long holes exceeding 20×D and micro cavities in heat-resistant alloys require a combination of deep hole drilling and electrical discharge machining (EDM) to achieve high-aspect-ratio features with micron-level tolerances.

Neway AeroTech specializes in combining precision EDM and CNC drilling for components made from Inconel 718, CMSX-4, and Rene 41 to create deep bores, internal slots, and angular cooling channels.

Core Technology of EDM for Long Hole Components

Combining CNC drilling and EDM enables accurate, burr-free holes in nickel-based superalloys where mechanical methods fall short.

Start-hole EDM for pilot bores <0.5 mm

Sinker EDM for internal cavity formation

Rotary and orbital EDM to form angled or curved passages

Hybrid EDM-drilling workflow for length-to-diameter ratios above 20×D in CMSX and Inconel

EDM provides minimal thermal damage and superior shape control in hard-to-machine alloys.

Typical Superalloy Materials for EDM-Drilled Features

Alloy | Max Temp (°C) | Hardness (HRC) | Typical Applications |

|---|---|---|---|

704 | 44 | Deep cooling channels | |

1140 | 37 | Film cooling impingement bores | |

980 | 40 | Long axial bores, internal splines | |

1175 | 32 | Exhaust liners, micro cavity rings |

EDM is used when geometry complexity or tool deflection limits conventional drilling approaches.

Case Study: CMSX-4 Long Hole EDM Cooled Turbine Liner

Project Background

A leading aerospace client required 0.4 mm diameter holes across a 10 mm wall thickness at a 35° angle in a CMSX-4 turbine liner. Mechanical drilling caused burn marks and crack initiation. EDM achieved hole accuracy within ±0.008 mm and a recast layer below 2 μm.

Typical Long Hole EDM Component Models and Applications

Part Model | Description | Material | Hole Depth | Industry |

|---|---|---|---|---|

LHC-320 | Impingement ring with 120 radial holes, 22×D | CMSX-4 | 11 mm | |

HTB-150 | Heat transfer block with serpentine channels | Inconel 718 | 15×D | |

ECC-200 | Engine chamber core with intersecting microbores | Rene 41 | 18×D | |

PRF-140 | Pressure ring with angular vent paths | Hastelloy X | 10×D |

Component functionality depends on precision fluid and gas flow paths created via hybrid EDM-drilling techniques.

EDM Machining Challenges for Long Hole Superalloy Components

Aspect ratios >20×D require rotary EDM and real-time flushing

Recast layer control must be under 2 μm for fatigue-critical parts

Angular bores >30° complicate start-hole alignment and electrode pathing

Thermal conductivity variation causes inconsistent spark erosion and dimensional deviation

Surface oxidation in Inconel requires passivation after EDM to prevent corrosion

Solutions for EDM Drilled Superalloy Geometries

Start-hole EDM + orbital drilling created 0.35 mm holes in CMSX-4 with 6 μm roundness deviation

Rotary EDM with flushing removed debris at 100 bar to prevent spark shorting in >20 mm holes

Recast layer polishing using electrochemical deburring (ECD) reduced surface roughness to Ra 0.4 μm

Multi-angle fixturing ensured ±0.005 mm positional accuracy for angled bores

Heat-treated parts retained hardness and structure post-EDM

Results and Verification

Manufacturing Methods

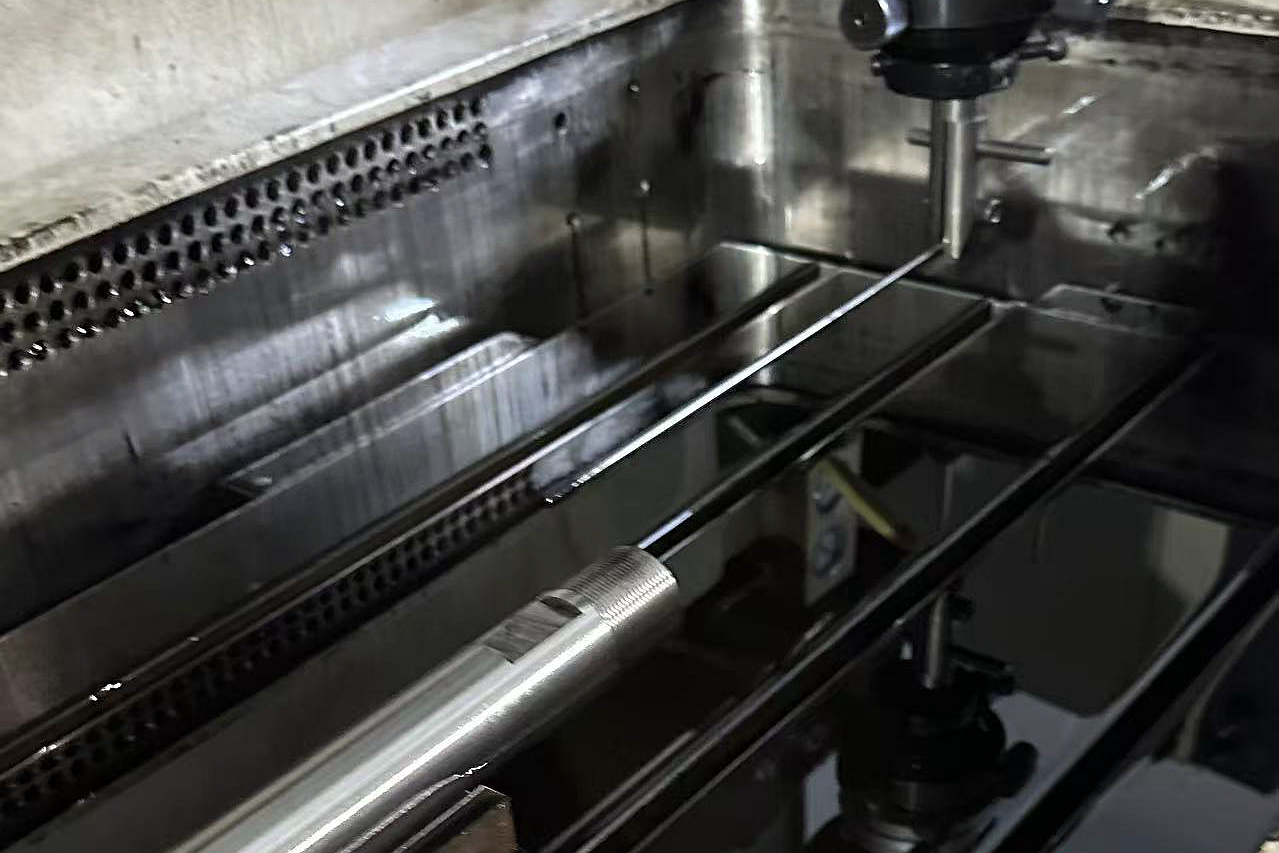

Components began as vacuum investment cast blanks or forged rings. Deep hole drilling was followed by rotary or sinker EDM for finishing. Tool paths were programmed using 3D simulation and verified via bore profile mapping.

Precision Finishing

Long holes were polished via post-EDM cycle with recast removal to 1.5 μm. Final dimensions: ±0.008 mm tolerance, Ra 0.3–0.5 μm. Threaded cavities were sinker-EDM cut to ISO 6g precision using hardened copper-tungsten electrodes.

Post-Processing

Parts underwent HIP and stress-relief annealing at 870°C, followed by thermal barrier coating (TBC) where specified. Surface passivation was applied on Inconel to prevent oxidation from EDM residues.

Inspection

CMM confirmed bore positions and straightness within 0.006 mm. SEM verified recast integrity and hole entrance. X-ray was used for complex intersecting features. GDMS ensured material chemistry within ±0.03 wt%.

FAQs

What is the thinnest hole EDM can produce in Inconel 718?

How do you handle bore alignment in angled multi-axis EDM drilling?

What recast layer thickness is acceptable for fatigue-critical aerospace parts?

Can EDM be used after CNC machining without thermal distortion?

What are the common inspection methods for internal EDM features?