Haynes 188 Superalloy 3D Printed Custom Parts Additive Manufacturing Service

Introduction to Haynes 188 Additive Manufacturing

Haynes 188 is a cobalt-based superalloy known for its outstanding strength, oxidation resistance, and thermal stability at temperatures up to 1095°C. It is widely used in gas turbines, combustors, afterburners, and hot-section engine components where conventional alloys fail.

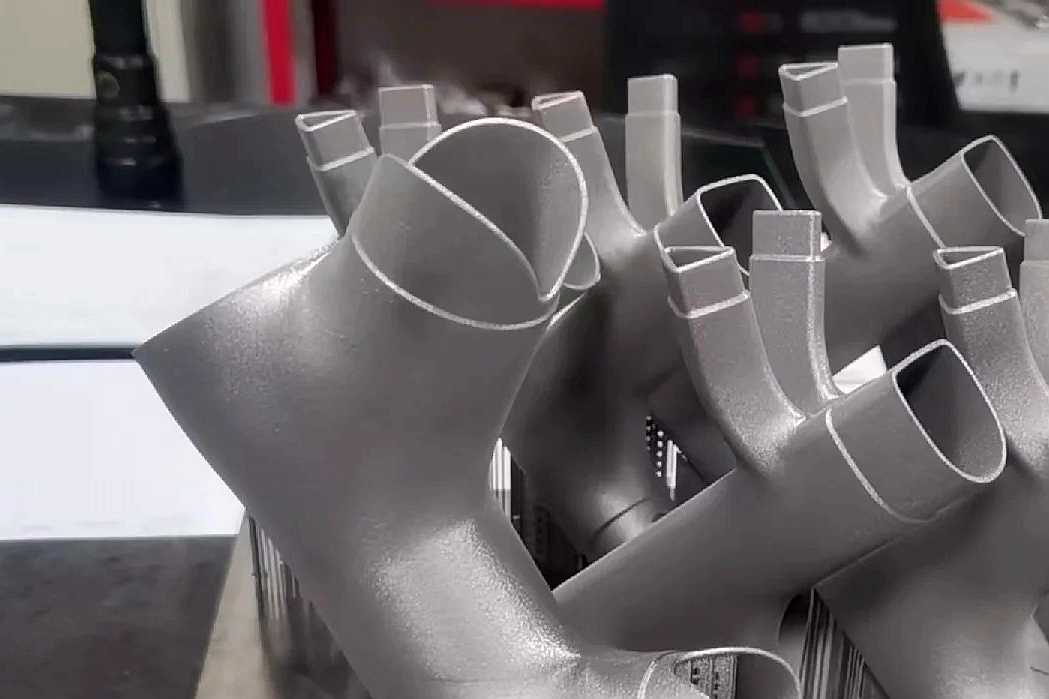

At Neway Aerotech, our superalloy 3D printing services enable the precision manufacturing of custom Haynes 188 parts using Selective Laser Melting (SLM) for complex geometries and superior high-temperature performance.

SLM Process Capabilities for Haynes 188 Components

Manufacturing Parameters

Parameter | Value | Description |

|---|---|---|

Printing Technology | Selective Laser Melting (SLM) | Enables high-resolution, complex shape fabrication |

Layer Thickness | 30–50 µm | Supports thin walls, ducts, and lattice structures |

Chamber Atmosphere | Argon, O₂ < 100 ppm | Prevents oxidation during printing |

Post-Processing | HIP, solution annealing, aging | Enhances fatigue and creep properties |

Tolerances Achievable | ±0.05 mm | Suitable for combustion chamber and nozzle features |

Why Haynes 188 is Ideal for Additive Manufacturing

Property | Value | Functional Benefit |

|---|---|---|

Temperature Limit | Up to 1095°C | Suitable for combustor liners and afterburner ducts |

Oxidation Resistance | Excellent | Maintains integrity in high-velocity flame environments |

Creep Resistance | Stable at >1000°C | Long-term durability in hot zones |

Weldability | Good in AM | Crack-resistant under rapid cooling |

Ductility & Fatigue Strength | High | Reliable for cyclic thermal and mechanical loading |

Post-Treatment Strategy for Haynes 188 3D Printed Parts

HIP: 1180°C at 100 MPa for 4 hours to eliminate porosity.

Solution Annealing: 1175°C for 2 hours followed by air cooling.

Aging: Optional aging at 870°C to improve strength.

Machining: CNC finishing applied to precision bores, sealing surfaces, and threads.

Passivation and surface polishing used for combustion-exposed parts.

Case Study: Haynes 188 3D Printed Swirler for Aerospace Combustor

Project Background

A gas turbine manufacturer needed a custom swirler component for a high-temperature combustor. The part required intricate vanes, internal flow channels, and long-term operation at 1000°C. Traditional casting could not achieve the thin wall and channel geometry needed.

Manufacturing Workflow

Design: CAD model with 1 mm vane thickness and integrated flow diverters.

Material: Atomized Haynes 188 powder, D50 = 35 µm.

Printing: SLM with 40 µm layer thickness, 350 W laser.

Post-Processing: HIP + annealing + CNC machining of flanges and inner bores.

Inspection: CMM and X-ray NDT ensured dimensional and metallurgical compliance.

Results and Verification

The printed Haynes 188 swirler withstood 1200-hour cyclic flame testing at 980–1040°C without crack formation or oxidation damage. Final tensile strength exceeded 930 MPa, and internal passages maintained smooth, clean flow with no porosity detected via CT scan.

FAQs

What industries benefit most from 3D printed Haynes 188 components?

How does Haynes 188 compare to Inconel 625 or 718 in high-temperature use?

What is the maximum part size printable with Haynes 188 via SLM?

Are CT scans and X-ray inspections included for combustion components?

Can Haynes 188 be used for both rotating and static hot-section parts?