Haynes 188

Material Introduction

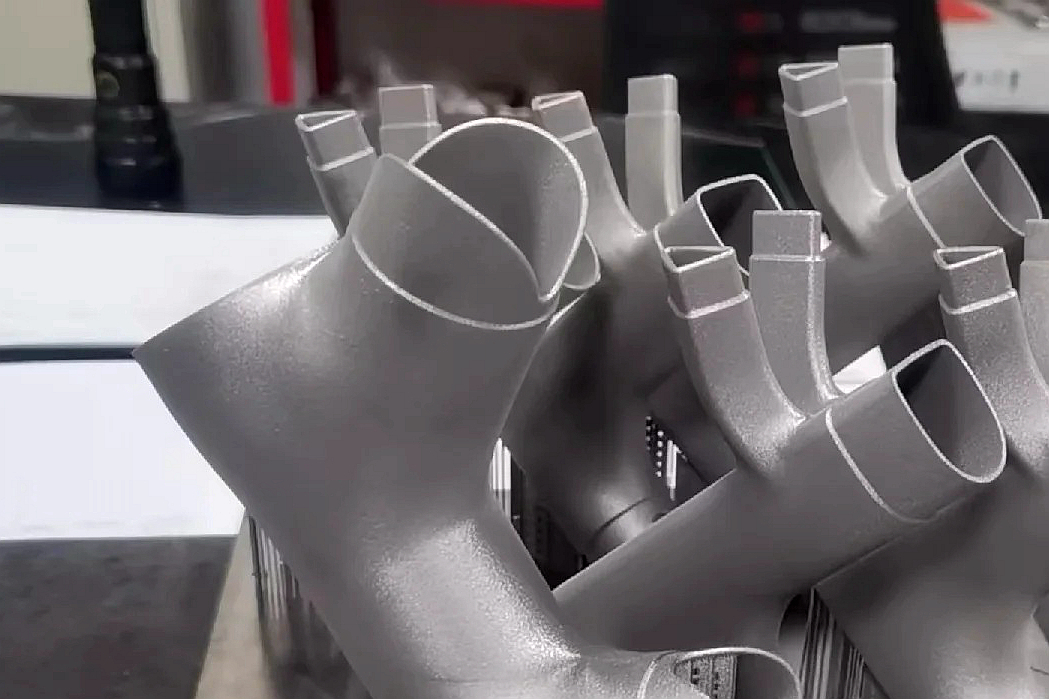

Haynes 188 is a cobalt–nickel–chromium–tungsten superalloy engineered for extreme high-temperature environments where oxidation, thermal fatigue, and creep resistance are critical to mission success. Known for its outstanding strength retention above 980°C, Haynes 188 is widely used in aerospace, power generation, and industrial gas turbine systems. When processed through advanced metal additive manufacturing platforms, such as Neway AeroTech’s high-temperature superalloy 3D printing, Haynes 188 enables designers to create lightweight, optimized geometries with internal cooling channels, lattice structures, and thin-wall profiles that would be difficult or impossible to produce via traditional casting or forging methods. Its exceptional oxidation resistance, excellent metallurgical stability, and strong weldability make it a premium material for components that must survive sustained thermal cycling, corrosive exhaust gases, and extreme mechanical loading.

International Names or Representative Grades

Country/Region | Common Name | Representative Grades |

|---|---|---|

USA | Haynes 188 | Alloy 188 |

Europe | Co-Ni-Cr-W Superalloy | 2.4684 |

Japan | High-Temperature Cobalt Alloy | Alloy 188 |

China | GH5188 | GH188 |

Aerospace Industry | Cobalt-Base Heat-Resistant Alloy | 188 |

Alternative Material Options

For applications requiring different performance balances, several alternatives may be considered based on temperature range, oxidation demands, or cost. Nickel-based superalloys, such as Inconel 738 and Inconel 939, offer exceptional creep strength at elevated temperatures and are well-suited for use in turbine blades. For even higher durability, single-crystal alloys like CMSX-4 or directionally solidified superalloys produced through directional casting deliver extreme long-term thermal stability. Where chemical corrosion is the primary concern, molybdenum-rich alloys such as Hastelloy X provide outstanding resistance to oxidizing and reducing environments. Lightweight alternatives such as Ti-6Al-2Sn-4Zr-6Mo may be chosen when high specific strength is required at moderate temperatures. These options enable designers to tailor material selections according to cost, heat tolerance, and structural demands.

Design Purpose

Haynes 188 was originally designed for severe high-temperature oxidizing environments commonly found in combustion chambers, turbine exhaust sections, and aerospace propulsion systems. Its composition of cobalt, nickel, chromium, and tungsten delivers excellent thermal stability, oxidation resistance, and creep strength that far exceeds that of conventional nickel alloys. In additive manufacturing, the intention expands to producing conformal-cooled, lightweight, topology-optimized structures that reduce mass while improving thermal efficiency, fuel performance, and long-term durability in extreme service conditions.

Chemical Composition (Typical Range)

Element | Composition (%) |

|---|---|

Cobalt (Co) | Balance |

Nickel (Ni) | 22 |

Chromium (Cr) | 22 |

Tungsten (W) | 14 |

Iron (Fe) | ≤ 3 |

Manganese (Mn) | ≤ 1.25 |

Silicon (Si) | ≤ 0.5 |

Carbon (C) | 0.06–0.14 |

Physical Properties

Property | Value |

|---|---|

Density | ~9.1 g/cm³ |

Melting Point | ~1260–1355°C |

Thermal Conductivity | 10–12 W/m·K |

Electrical Resistivity | ~1.1 μΩ·m |

Specific Heat Capacity | ~430 J/kg·K |

Mechanical Properties

Property | Typical Value |

|---|---|

Tensile Strength | 760–860 MPa |

Yield Strength | 450–520 MPa |

Elongation | 35–50% |

Hardness | 220–260 HB |

High-Temperature Strength | Excellent up to 1100°C |

Key Material Characteristics

Exceptional high-temperature oxidation resistance for turbine and combustion surfaces

Outstanding thermal fatigue resistance under repeated heating and cooling cycles

Strong creep resistance at temperatures exceeding 980°C

Excellent ductility and toughness across a wide temperature range

Stable microstructure ideal for long-term exposure in high-heat environments

Excellent weldability and crack resistance during additive fusion processes

High resistance to hot corrosion and combustion gas environments

Superior performance in thin-wall structures and complex geometries

Strong metallurgical stability during rapid thermal cycling in aerospace engines

Suitable for environments involving extreme mechanical stress and elevated temperatures

Manufacturability in Different Processes

Additive manufacturing: Powder bed fusion enables the production of high-precision, high-temperature components with complex internal cooling channels using Neway’s advanced superalloy 3D printing technology.

CNC machining: Work-hardening behavior requires optimized cutting strategies supported by superalloy CNC machining.

EDM processing: Intricate profiles and cooling passages are efficiently produced through superalloy EDM.

Deep hole drilling: Maintains dimensional stability under thermal load when processed using advanced deep hole drilling techniques.

Heat treatment: Microstructure refinement and stress relief are performed through precise superalloy heat treatment cycles.

Welding: High weldability enables effective joining using controlled superalloy welding.

Investment casting: Applicable through controlled equiaxed casting for specific shapes requiring thermal fatigue functionality.

Suitable Post-Processing Methods

Hot Isostatic Pressing (HIP) with advanced HIP processing to remove porosity and increase fatigue strength

High-temperature heat treatment to maximize creep resistance and microstructural uniformity

Surface machining for precise tolerance control in turbine or combustor sections

Oxidation-resistant coatings, such as thermal barrier coating for improved thermal cycling performance

Non-destructive inspection via advanced material testing and analysis

Polishing or abrasive finishing to reduce drag and enhance thermal flow in engine components

EDM finishing for complex internal pathways requiring smooth thermal flow

Common Industries and Applications

Aerospace turbine components, combustor liners, exhaust segments, and fuel nozzle structures

Power generation gas turbine hot-section elements

Industrial furnace components exposed to extreme oxidation

Energy sector high-temperature assemblies and heat exchangers

Defense propulsion components requiring high thermal endurance

Chemical processing environments involving corrosive gases and extreme heat

When to Choose This Material

When components must withstand temperatures above 980°C with long-term oxidation resistance

When thermal fatigue is a primary design concern for turbine or exhaust systems

When thin-wall, lightweight, or conformal-cooled structures must be produced via additive manufacturing

When mechanical loading remains severe at elevated temperatures

When corrosion and hot-gas oxidation demand exceptional alloy performance

When components require long service life in cyclic thermal environments

When nickel alloys fail due to creep or oxidation limitations

When aerospace, energy, or defense systems require maximum high-temperature reliability