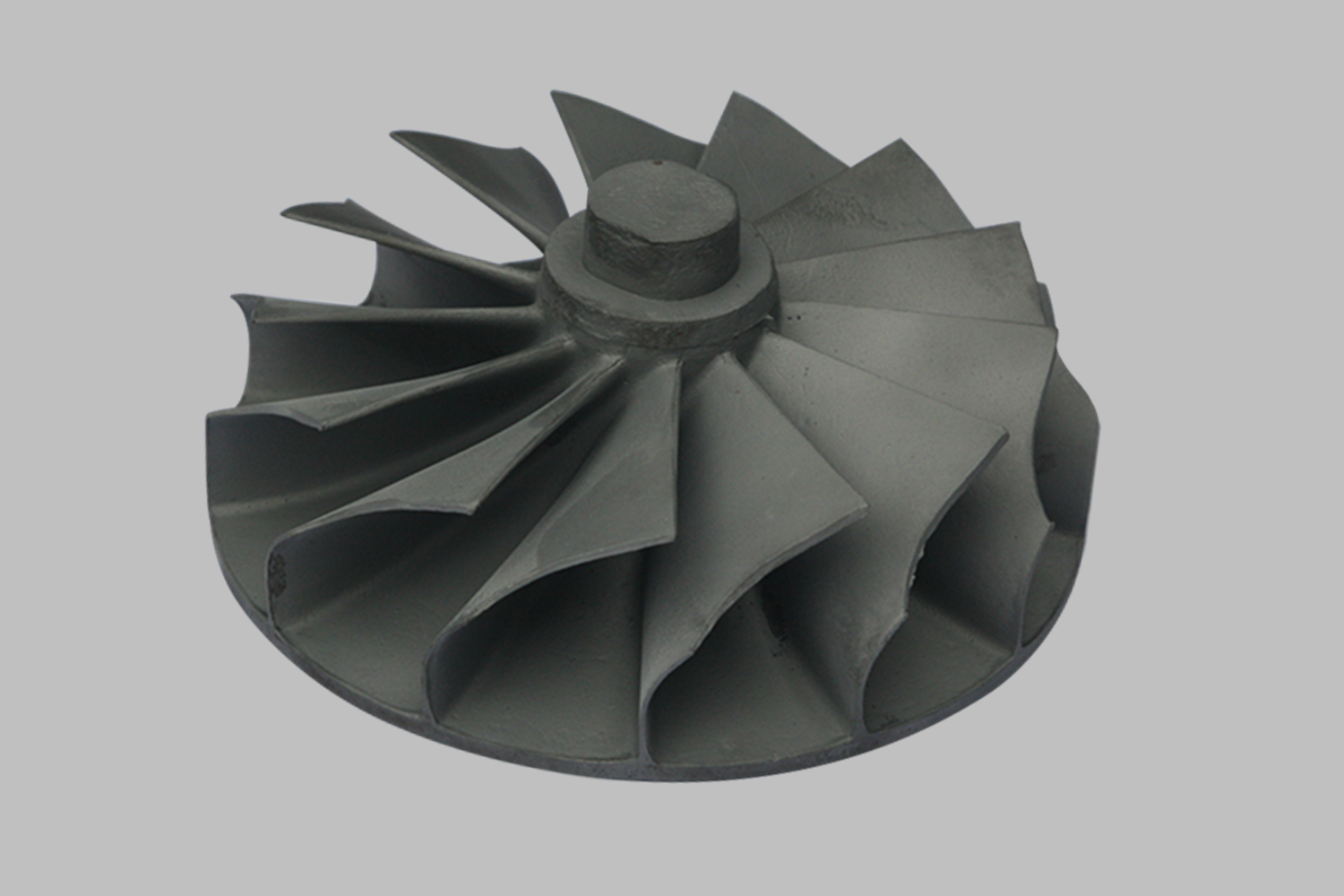

Superalloy Vacuum Casting Turbine Components Production Factory

Introduction

Neway AeroTech manufactures high-performance turbine components using advanced vacuum investment casting technology. Leveraging specialized superalloys such as Inconel and CMSX alloys, we produce turbine components, achieving dimensional tolerances within ±0.05 mm and surface finishes as precise as Ra ≤1.6 µm.

Our facility incorporates stringent quality assurance processes and precision-controlled environments, enabling turbine parts to operate reliably under temperatures exceeding 1100°C, meeting demanding aerospace and power-generation industry standards.

Core Challenges of Vacuum Casting Turbine Components

Manufacturing turbine components from high-temperature alloys such as CMSX-4, Inconel 713C, and Hastelloy X poses significant technical challenges:

Achieving uniform solidification and controlling grain structures (single-crystal, directional, equiaxed).

High melting temperatures (1300-1450°C) requiring advanced vacuum furnace capabilities.

Strict dimensional accuracy within ±0.05 mm for complex geometries.

Superior surface integrity (Ra ≤1.6 µm) essential for aerodynamic and thermal efficiency.

Detailed Vacuum Casting Process

The vacuum casting process for turbine components consists of the following key stages:

Wax Pattern Formation: Precision wax patterns crafted using CNC or additive manufacturing technologies.

Ceramic Shell Development: Layered ceramic shell coating through repeated slurry dipping and refractory sand application.

Dewaxing and Shell Firing: Removal of wax via autoclave (approximately 150°C) followed by firing at approximately 1000°C for shell strength.

Vacuum Melting and Pouring: Alloy melting in high-vacuum environments (<0.01 Pa) to eliminate oxidation and inclusions, ensuring purity.

Controlled Solidification: Precision control of cooling rates and directional solidification to achieve desired grain structures and superior mechanical properties.

Shell Removal and Finishing: Mechanical and chemical removal of ceramic shells, final CNC machining for precise dimensional adherence, and surface finish enhancement.

Comparison of Turbine Component Manufacturing Methods

Method | Dimensional Accuracy | Surface Finish (Ra) | Grain Structure Control | Mechanical Properties | Cost Efficiency |

|---|---|---|---|---|---|

Vacuum Investment Casting | ±0.05 mm | ≤1.6 µm | Excellent | Superior | Medium |

Powder Metallurgy | ±0.03 mm | ≤1.2 µm | Excellent | Superior | High |

Precision Forging | ±0.2 mm | ≤3.2 µm | Good | Good | Medium |

CNC Machining | ±0.01 mm | ≤0.8 µm | Limited | Good | High |

Manufacturing Method Selection Criteria

Optimal selection of manufacturing methods for turbine components includes:

Vacuum Investment Casting: Best suited for complex shapes, acceptable dimensional accuracy (±0.05 mm), excellent surface quality (Ra ≤1.6 µm), and specialized grain structures.

Powder Metallurgy: Ideal for ultra-high mechanical strength and precision (±0.03 mm) in advanced aerospace turbines.

Precision Forging: Appropriate for moderately complex designs with good mechanical properties, suitable for large-scale production.

CNC Machining: Effective for prototypes, limited production, or finishing operations demanding extremely tight tolerances (±0.01 mm).

Superalloy Material Performance Matrix

Alloy | Melting Range (°C) | Max Service Temp (°C) | Tensile Strength (MPa) | Oxidation Resistance | Typical Applications |

|---|---|---|---|---|---|

1315-1345 | 1150 | 1250 | Superior | Single-crystal turbine blades | |

1310-1355 | 950 | 1200 | Exceptional | High-temp turbine components | |

1260-1355 | 900 | 860 | Superior | Combustion chamber components | |

1320-1360 | 950 | 1200 | Excellent | High-temperature gas turbines | |

1320-1365 | 1150 | 1150 | Superior | Advanced aero-engine components | |

1260-1350 | 800 | 870 | Excellent | Wear-resistant components |

Material Selection Guidelines

Strategic alloy selection includes:

CMSX-4: Ideal for single-crystal turbine blades requiring extreme creep resistance and strength at temperatures up to 1150°C.

Inconel 713C: Optimal for high-strength turbine components operating at elevated temperatures (up to 950°C).

Hastelloy X: Suitable for combustion chambers needing superior oxidation resistance and moderate tensile strength (860 MPa).

Nimonic 90: Best choice for high-temperature turbine parts requiring high tensile (1200 MPa) and creep resistance (950°C).

Rene N5: Recommended for advanced aerospace turbine components due to extraordinary fatigue strength at extreme service temperatures (1150°C).

Stellite 6: Chosen for turbine applications demanding high wear resistance at moderate temperatures (800°C).

Key Post-processing Techniques

Essential post-processing includes:

Hot Isostatic Pressing (HIP): Eliminates internal porosity, enhancing fatigue life significantly.

Thermal Barrier Coating (TBC): Ceramic coatings reduce component surface temperatures, prolonging operational lifespan.

Precision CNC Machining: Final dimension adjustments achieving aerospace-grade precision (±0.01 mm).

Controlled Heat Treatment: Optimized annealing and aging cycles enhance structural integrity and performance.

Testing Methods and Quality Assurance

Neway AeroTech conducts comprehensive testing and quality assurance protocols, including:

Coordinate Measuring Machine (CMM): Verifies precise dimensions (±0.005 mm accuracy).

X-ray Non-destructive Testing: Identifies internal defects and porosity.

Metallographic Microscopy: Evaluates grain structures and microstructural integrity.

Tensile Testing: Ensures tensile and yield strengths meet specifications.

Our rigorous quality control procedures adhere strictly to AS9100 standards, guaranteeing reliability under extreme operational environments.

Case Study: CMSX-4 Single-Crystal Turbine Blades

Neway AeroTech successfully supplied CMSX-4 turbine blades for aerospace applications, demonstrating:

Operating Temperature: Continuous operation at 1150°C

Fatigue Life: Enhanced by 40%

Dimensional Precision: ±0.03 mm maintained

Certification: Fully compliant with AS9100 aerospace standards

FAQs

What are the advantages of vacuum investment casting for turbine components?

Which alloys are best suited for high-temperature turbine applications?

What dimensional accuracy can vacuum casting achieve?

How do post-processing treatments improve turbine component performance?

What testing methods ensure turbine component quality and reliability?