Stellite Alloy Insulating Shields 3D Printed for High-Temperature Applications

Introduction

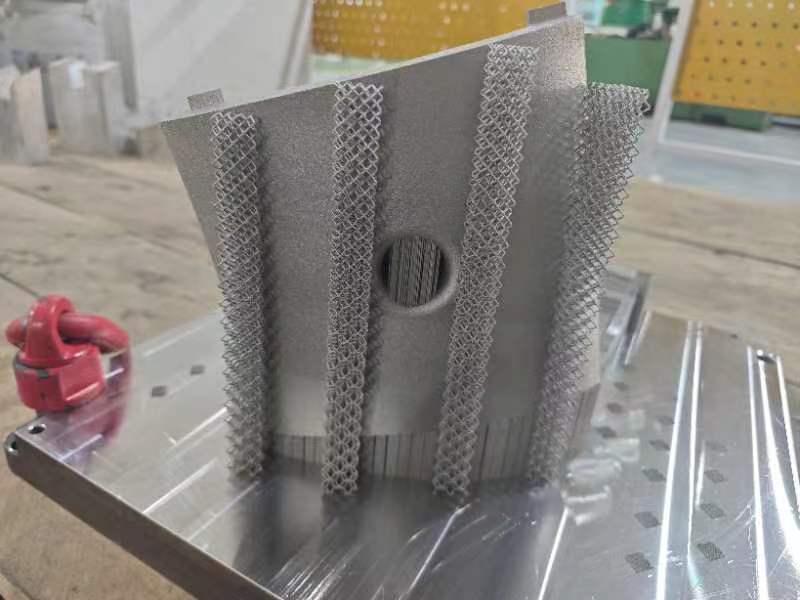

Stellite alloys are renowned for their outstanding wear resistance, oxidation stability, and mechanical strength at elevated temperatures, making them the perfect material for manufacturing high-performance insulating shields. At Neway AeroTech, we specialize in 3D printing services for Stellite alloys, delivering complex, durable, lightweight insulating shields optimized for aerospace, energy, and industrial high-temperature applications.

Leveraging advanced Selective Laser Melting (SLM) technology, Neway produces customized Stellite components with superior thermal and mechanical performance, ensuring reliability under extreme operational conditions.

Core Manufacturing Challenges for Stellite Insulating Shields

Manufacturing 3D printed insulating shields from Stellite 6 and Stellite 21 presents specific challenges:

Managing residual stresses and minimizing distortion during high-energy layer-by-layer fusion processes caused by the alloy's low thermal conductivity (11–14 W/m·K).

Achieving near-full density levels (>99.5%) to maintain optimal mechanical strength and prevent early fatigue failures.

Maintaining dimensional tolerances within ±0.05 mm, critical for achieving assembly alignment and ensuring dynamic performance.

Producing surface finishes Ra ≤5 µm, essential for minimizing oxidation sites and ensuring longer service intervals.

3D Printing Process for Stellite Alloy Insulating Shields

Our additive manufacturing process for Stellite heat shields includes:

Powder Quality Control: Using gas-atomized Stellite powders with particle sizes between 15–45 µm, ensuring consistent layer formation.

Selective Laser Melting (SLM): Controlled laser melting in an argon atmosphere to eliminate oxidation and promote high-density part formation.

Process Optimization: Fine-tuning scan speed (~600–800 mm/s), laser power (250–400 W), and hatch spacing (~0.1–0.13 mm) to balance energy input and minimize residual stresses.

Support Removal and HIP Treatment: Removal of supports followed by Hot Isostatic Pressing (HIP) at 1200°C and 100 MPa for 4 hours to eliminate internal defects.

Precision CNC Machining: Achieving final dimensional precision of ±0.01 mm and surface finishes Ra ≤1.6 µm on critical interfaces.

Heat Treatment: Applying solution annealing at 1150°C followed by air cooling to stabilize microstructure and enhance thermal fatigue performance.

Comparison of Manufacturing Methods for Stellite Insulating Shields

Manufacturing Method | Dimensional Accuracy | Surface Finish (Ra) | Thermal Stability | Wear Resistance | Cost Efficiency |

|---|---|---|---|---|---|

3D Printing (SLM) | ±0.05 mm | ≤5 µm | Superior (up to 950°C) | Superior (HRC 43–55) | Medium |

Vacuum Investment Casting | ±0.1 mm | ≤3.2 µm | Good (up to 800°C) | Good | Medium |

CNC Machining (from Solid) | ±0.01 mm | ≤0.8 µm | Excellent (above 950°C) | Good | High |

Manufacturing Method Selection Strategy

Choosing the right manufacturing method depends on part complexity, performance demands, and cost:

3D Printing (SLM): Best for highly complex and lightweight insulating shields requiring wall thicknesses as low as 1.0 mm and intricate internal lattice structures.

Vacuum Investment Casting: More suitable for simpler geometries that tolerate ±0.1 mm dimensional deviations.

CNC Machining (from Solid): Ideal for solid shields needing ultra-high precision (±0.01 mm) but at the cost of heavier component weight.

Stellite Alloy Performance Matrix

Alloy Material | Max Service Temp (°C) | Hardness (HRC) | Creep Resistance | Oxidation Resistance | Typical Applications |

|---|---|---|---|---|---|

800 | 43–50 | Good (up to 600°C) | Excellent | Thermal shields, erosion barriers | |

800 | 35–45 | Moderate (below 500°C) | Excellent | High-temperature shields, structural parts | |

850 | 48–55 | Good (up to 650°C) | Good | Abrasion-resistant insulating parts | |

800 | 42–48 | Good (600°C continuous) | Excellent | Rotor shields, wear-resistant panels | |

780 | 35–42 | Moderate (up to 500°C) | Good | Exhaust shielding components | |

950 | 30–38 | Good (up to 700°C) | Excellent | High-temperature structural shields |

Alloy Selection Strategy for Insulating Shields

Selecting the right Stellite alloy ensures optimal thermal protection and service life:

Stellite 6: Standard for insulating shields where up to 800°C operation, high wear, and corrosion resistance are necessary.

Stellite 21: Chosen for applications needing a good balance of ductility and oxidation resistance with moderate creep requirements.

Stellite 12: Recommended for shields exposed to abrasive particulates and cyclic thermal loading at temperatures up to 850°C.

Stellite 6B: Ideal for rotating shields or covers requiring fatigue resistance and wear protection.

Stellite 20: Cost-effective option for exhaust system shielding under moderate thermal and chemical exposure.

Stellite 25: Preferred for aerospace and energy sectors where high-temperature operation up to 950°C with oxidation resistance is critical.

Key Post-processing Techniques

Essential post-processing methods include:

Hot Isostatic Pressing (HIP): Achieves full-density parts (>99.9%) and improves fatigue performance by closing internal pores.

Precision CNC Machining: Fine-tuning surfaces and tolerances for tight assembly requirements (±0.01 mm).

Heat Treatment: Solution treatment at 1150°C enhances microstructural uniformity and mechanical reliability.

Surface Coating: The application of advanced TBC (Thermal Barrier Coatings) sometimes extends thermal resistance beyond 1000°C.

Testing Methods and Quality Assurance

All Neway AeroTech insulating shields undergo rigorous aerospace-grade validation:

Coordinate Measuring Machine (CMM): Dimensional verification to ±0.005 mm accuracy.

X-ray Inspection: Non-destructive inspection of internal integrity and pore distribution.

Metallographic Microscopy: Microstructure analysis for carbide distribution and phase balance.

Tensile Testing: Mechanical property validation ensuring specified strength and elongation.

Case Study: 3D Printed Stellite 6 Insulating Shields

Neway AeroTech produced 3D printed Stellite 6 insulating shields for turbine engine hot sections:

Service Temperature: Continuous exposure up to 800°C

Dimensional Precision: Maintained ±0.05 mm across complex freeform geometries

Surface Finish: Achieved Ra ≤4.5 µm for minimized oxidation sites

Certification: Fully compliant with AS9100 aerospace quality standards

FAQs

Why are Stellite alloys suitable for 3D printed high-temperature insulating shields?

What dimensional tolerances can Neway AeroTech achieve for 3D printed Stellite shields?

How does Hot Isostatic Pressing (HIP) improve the reliability of 3D printed Stellite components?

Which Stellite grades are recommended for insulating shields operating above 800°C?

What quality control standards does Neway AeroTech use for manufacturing insulating shields?