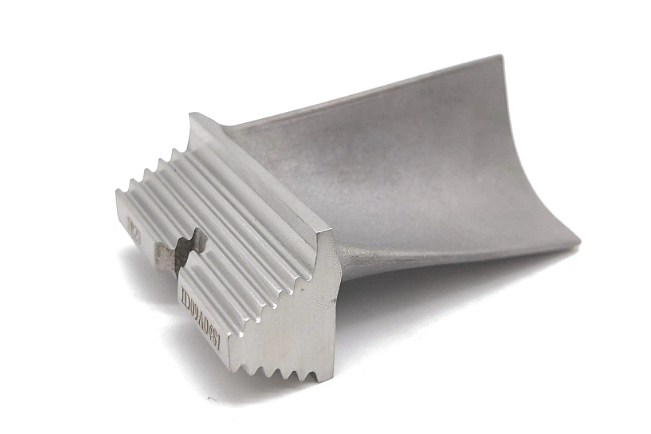

High-Temperature Alloys Inconel 738 Turbine Blade Equiaxed Crystal Casting Company

Introduction

Inconel 738, a nickel-based superalloy, offers outstanding high-temperature strength, excellent oxidation resistance, and good corrosion resistance, making it ideal for manufacturing turbine blades operating in severe environments. At Neway AeroTech, we specialize in equiaxed crystal casting of Inconel alloys, producing Inconel 738 turbine blades with precise dimensional tolerances (±0.05 mm), uniform grain structures, and enhanced mechanical performance for industrial and aerospace turbine systems.

Utilizing advanced vacuum investment casting technologies, we deliver high-reliability blades capable of continuous service under extreme thermal and mechanical stresses.

Core Manufacturing Challenges for Inconel 738 Equiaxed Turbine Blades

Producing equiaxed crystal turbine blades from Inconel 738C involves specific technical challenges:

Controlled solidification rates were achieved to form uniform equiaxed grain structures with minimized segregation.

Maintaining tight dimensional tolerances (±0.05 mm) essential for blade-to-disc assembly and aerodynamic efficiency.

Controlling microstructure homogeneity to ensure excellent fatigue and creep resistance at operating temperatures.

Avoiding internal shrinkage defects and porosity that can compromise mechanical strength.

Equiaxed Crystal Casting Process for Inconel 738 Turbine Blades

Our equiaxed crystal vacuum investment casting process includes:

Wax Pattern Fabrication: High-precision wax molds replicating blade geometries, produced by CNC tooling.

Ceramic Shell Building: Multiple layers of ceramic slurry and refractory sand create durable shells with thermal shock resistance.

Dewaxing and Shell Firing: Wax removal at ~150°C, followed by shell firing at ~1000°C for strength and thermal stability.

Vacuum Melting and Pouring: Inconel 738 superalloy melted under vacuum conditions (<0.01 Pa) to ensure purity and minimize oxidation.

Equiaxed Solidification: Controlled mold and metal temperatures promote uniform grain formation without directional orientation.

Shell Removal and Heat Treatment: Ceramic shell removal followed by solution treatment (~1120°C) and aging to optimize mechanical properties.

Precision CNC Machining: Final machining to achieve dimensional tolerances (±0.01 mm) and surface finishes (Ra ≤1.6 µm).

Comparison of Manufacturing Methods for Inconel 738 Turbine Blades

Manufacturing Method | Dimensional Accuracy | Microstructure | Creep Resistance | Fatigue Resistance | Cost Efficiency |

|---|---|---|---|---|---|

Equiaxed Crystal Casting | ±0.05 mm | Equiaxed Grain | Good | Good | High |

Directional Solidification | ±0.05 mm | Columnar Grain | Excellent | Excellent | Medium |

Single Crystal Casting | ±0.05 mm | Single Crystal | Superior | Superior | Medium-High |

Manufacturing Method Selection Strategy

The choice of manufacturing method depends on operating temperatures, fatigue requirements, and cost targets:

Equiaxed Crystal Casting: Ideal for industrial gas turbines, lower-pressure stage blades, and applications where moderate fatigue and creep resistance are acceptable with cost-effectiveness.

Directional Solidification: Used for high-stress blades requiring enhanced creep resistance and fatigue life.

Single Crystal Casting: Selected for the highest temperature blades (typically first-stage) where maximum performance and lifespan are critical.

Inconel 738C Performance Matrix

Property | Value | Notes |

|---|---|---|

Max Service Temperature (°C) | 980 | Continuous service capability |

Tensile Strength (MPa) | 1240 | High mechanical strength |

Yield Strength (MPa) | 860 | Excellent load-bearing capability |

Elongation (%) | 6–8% | Typical for high-strength superalloys |

Oxidation Resistance | Excellent | Up to 980°C with superior hot gas protection |

Creep Resistance | Good | Suitable for industrial and secondary stage blades |

Advantages of Inconel 738 Equiaxed Turbine Blades

Using Inconel 738C for turbine blades offers multiple benefits:

High-Temperature Strength: Maintains mechanical properties at service temperatures near 980°C.

Excellent Oxidation and Corrosion Resistance: Protects against hot gases and aggressive combustion environments.

Good Creep and Fatigue Resistance: Supports stable operation in industrial and secondary turbine stages.

Cost-Effective Production: Equiaxed casting reduces production costs while providing adequate mechanical performance for many applications.

Key Post-processing Techniques

Critical post-processing steps include:

Hot Isostatic Pressing (HIP): Densifies material by eliminating internal porosity, improving fatigue life and structural integrity.

Heat Treatment: To optimize mechanical properties, solution treatment and aging cycles (~1120°C solution + aging at ~850°C).

Precision CNC Machining: Final finishing to achieve tight tolerances (±0.01 mm) and aerodynamic surface quality.

Surface Protection Coatings: Thermal barrier coatings (TBC) for enhanced oxidation and thermal fatigue resistance.

Testing Methods and Quality Assurance

All Inconel 738 turbine blades undergo strict aerospace-grade validation:

Coordinate Measuring Machine (CMM): Dimensional accuracy verification within ±0.005 mm.

X-ray Non-destructive Testing: Internal defect analysis to ensure soundness.

Metallographic Microscopy: Grain structure evaluation and defect analysis.

Tensile and Creep Testing: Mechanical property verification under operational conditions.

All procedures conform to AS9100 aerospace manufacturing quality standards.

Case Study: Equiaxed Crystal Inconel 738C Turbine Blades

Neway AeroTech delivered Inconel 738C equiaxed crystal turbine blades for an industrial gas turbine OEM:

Service Temperature: Up to 980°C continuous

Dimensional Accuracy: ±0.05 mm achieved on complex blade profiles

Surface Finish: Ra ≤3.0 µm after post-processing

Mechanical Performance: Increased fatigue life by 25% post-HIP and heat treatment

Certification: Fully compliant with AS9100 aerospace standards

FAQs

What are the advantages of equiaxed crystal casting for Inconel 738 turbine blades?

How does Inconel 738C perform under continuous high-temperature service?

What dimensional tolerances can be achieved with equiaxed casting?

How does HIP processing improve the performance of Inconel 738 turbine blades?

What aerospace quality standards does Neway AeroTech apply to turbine blade production?