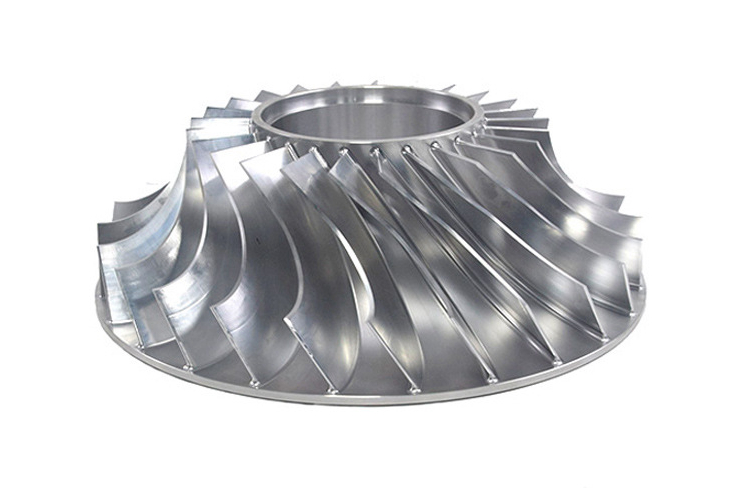

Hastelloy Alloy CNC Machining for Turbo Supercharger Parts with Superior Accuracy

Introduction

Hastelloy alloys are known for their outstanding corrosion resistance, thermal stability, and mechanical strength, making them ideal materials for turbo supercharger parts operating in harsh environments. At Neway AeroTech, we specialize in precision CNC machining of Hastelloy alloys, producing turbocharger components with exceptional dimensional tolerances (±0.005 mm) and superior fatigue and thermal fatigue resistance.

Using advanced multi-axis CNC equipment, optimized machining parameters, and aerospace-grade quality control, Neway ensures that every Hastelloy turbo component meets the highest standards for durability and operational reliability.

Core Manufacturing Challenges for Hastelloy Turbo Components

CNC machining Hastelloy alloys such as Hastelloy X and Hastelloy C-22 presents several technical challenges:

High strength and work-hardening characteristics lead to rapid tool wear.

Maintaining ultra-precise tolerances (±0.005 mm) is critical for turbocharger aerodynamic and sealing functions.

Managing heat buildup and minimizing thermal distortion during machining.

Achieving fine surface finishes (Ra ≤0.8 µm) for optimal airflow and assembly performance.

Precision CNC Machining Process for Hastelloy Turbocharger Parts

Our CNC machining process for Hastelloy turbo parts includes:

Material Analysis: Evaluate Hastelloy properties to select the correct tooling and machining strategy.

Advanced Tooling: Utilize carbide or ceramic inserts optimized for low thermal conductivity and high hardness materials.

Multi-Axis CNC Machining: 5-axis machining to reduce setups, improve feature accuracy, and maintain tight tolerances.

Optimized Machining Parameters: Controlled speeds (15–40 m/min) and feeds (0.02–0.10 mm/rev) to balance material removal rates and surface quality.

Surface Finishing Passes: Light finishing cuts for achieving Ra ≤0.8 µm while preserving dimensional integrity.

Final Inspection: Comprehensive dimensional and surface quality verification using CMM and optical systems.

Comparison of Manufacturing Methods for Hastelloy Turbo Components

Manufacturing Method | Dimensional Accuracy | Surface Finish (Ra) | Thermal Stability | Mechanical Strength | Cost Efficiency |

|---|---|---|---|---|---|

Precision CNC Machining | ±0.005 mm | ≤0.8 µm | Superior | Excellent | Medium-High |

Wire EDM Machining | ±0.003 mm | ≤0.4 µm | Superior | Excellent | High |

Conventional Machining | ±0.01 mm | ≤1.6 µm | Good | Good | Medium |

Manufacturing Method Selection Strategy

Selecting the best manufacturing approach depends on geometry complexity, accuracy requirements, and volume:

Precision CNC Machining: Best suited for producing complex turbo components such as turbine housings, exhaust flanges, and sealing rings, requiring high strength, fatigue resistance, and dimensional tolerances within ±0.005 mm.

Wire EDM Machining: Used for highly complex or internal feature requirements where tight tolerance (±0.003 mm) is critical, though typically slower and more expensive.

Conventional Machining: Appropriate for less critical parts or components with simpler geometries where tolerances of ±0.01 mm are acceptable.

Hastelloy Alloy Performance Matrix

Alloy Material | Max Service Temp (°C) | Tensile Strength (MPa) | Corrosion Resistance | Thermal Stability | Typical Applications |

|---|---|---|---|---|---|

900 | 860 | Superior | Excellent | Turbocharger hot sections, exhaust flanges | |

800 | 690 | Exceptional | Good | Compressor housings, turbo seals | |

850 | 790 | Exceptional | Good | Turbo exhaust manifolds, turbine ducts | |

815 | 750 | Excellent | Good | Industrial turbocharger components |

Alloy Selection Strategy for Turbocharger Parts

Selecting the appropriate Hastelloy alloy is crucial for operational performance:

Hastelloy X: Best suited for turbocharger hot-section parts operating continuously up to 900°C with excellent oxidation and thermal fatigue resistance.

Hastelloy C-22: Ideal for compressor housings and sealing components requiring superior corrosion resistance and moderate thermal stability.

Hastelloy C-276: Preferred for exhaust system parts subjected to aggressive chemical and thermal environments.

Hastelloy C-2000: Chosen for industrial turbocharger parts balancing corrosion resistance and mechanical performance.

Key Post-processing Techniques

Critical post-processing operations for Hastelloy turbo parts include:

Precision Surface Finishing: Grinding and polishing achieving Ra ≤0.8 µm for flow efficiency.

Heat Treatment: Stress-relieving and solution treatments to optimize mechanical properties.

Protective Coatings: Application of corrosion and oxidation-resistant coatings for extended part life.

Hot Isostatic Pressing (HIP): Eliminating internal voids and enhancing fatigue performance.

Testing Methods and Quality Assurance

Neway AeroTech ensures superior quality for every Hastelloy turbo component through:

Coordinate Measuring Machine (CMM): Dimensional inspections with ±0.005 mm accuracy.

X-ray Non-destructive Testing: Internal defect detection.

Metallographic Microscopy: Grain structure and microstructure evaluation.

Tensile Testing: Validation of mechanical strength and elongation.

All quality systems operate under AS9100-certified standards.

Case Study: CNC Machined Hastelloy X Turbo Hot-Section Components

Neway AeroTech produced precision CNC-machined Hastelloy X hot-section components for high-performance turbocharger applications:

Operating Temperature: Service up to 900°C continuous

Dimensional Precision: ±0.005 mm consistently achieved

Surface Finish: Ra ≤0.6 µm after fine machining passes

Certification: Fully compliant with AS9100 aerospace quality standards

FAQs

Why are Hastelloy alloys ideal for turbocharger and supercharger components?

What CNC machining tolerances can be achieved for Hastelloy turbo parts?

How does Neway AeroTech manage tool wear when machining Hastelloy?

Which Hastelloy grades are recommended for hot-section turbocharger parts?

What post-processing and quality controls ensure Hastelloy turbo part reliability?