Aerospace Superalloy Combustion Chamber Component SLS 3D Printing Service

Introduction to SLS 3D Printing for Aerospace Combustion Components

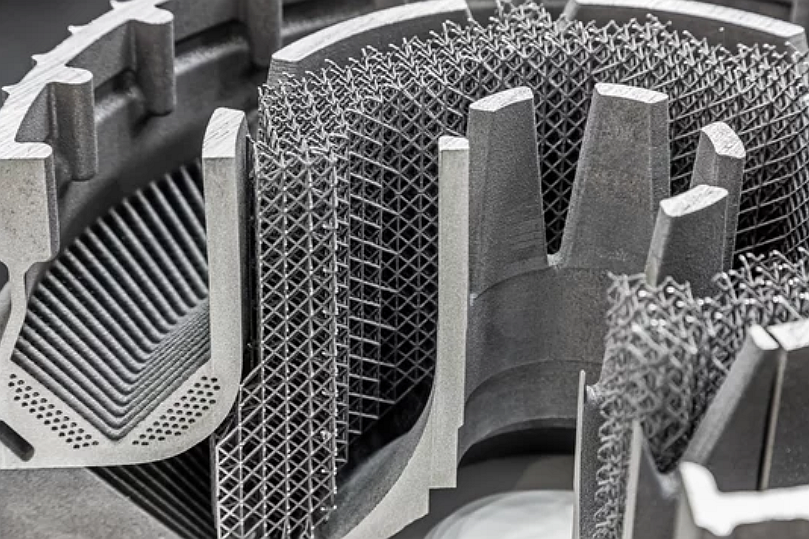

Selective Laser Sintering (SLS) is a reliable method for manufacturing complex combustion chamber components from aerospace-grade superalloys. This layer-wise powder fusion process ensures uniform density, controlled microstructure, and thermal integrity across intricate geometries under extreme heat and pressure.

At Neway Aerotech, our SLS 3D printing services support the fabrication of superalloy combustion parts for propulsion systems, aero engines, and turbine combustion assemblies.

SLS 3D Printing Overview

Process Capabilities

Parameter | Value |

|---|---|

Layer Thickness | 40–60 μm |

Minimum Feature Size | ~0.5 mm |

Dimensional Tolerance | ±0.1 mm per 100 mm |

Max Chamber Temperature | >1000°C for superalloy builds |

Density (after HIP) | ≥99.7% |

SLS enables the creation of lightweight lattice structures, internal cooling networks, and complex wall profiles in a single build cycle.

Why SLS for Aerospace Combustion Chambers?

Non-contact layer fusion preserves thin-wall geometry

Supports integration of complex features (cooling holes, lattice reinforcements, integrated ports)

High-resolution powder melting ensures mechanical performance in 1000°C+ environments

Fully compatible with post-processing such as HIP, EDM, and coating

Material Considerations

Common Superalloys for SLS Combustion Chambers

Material | Max Temperature (°C) | Strength @ 800°C (MPa) | Oxidation Resistance | Application Use Case |

|---|---|---|---|---|

700–750 | ~970 | Excellent | Aero combustor liners, fuel nozzle mounts | |

>980 | ~1100 | Superior | Turbine combustion cans, swirler bodies | |

>1000 | ~1200 | Excellent | Burner rings, igniter housings | |

~1175 | ~880 | Exceptional | Combustion walls in oxidizing gas paths |

Case Study: SLS Fabrication of Inconel 939 Combustion Liner Segment

Project Background

A customer in the aerospace and aviation sector required a one-piece combustion liner with 3D-printed internal cooling channels, lattice stiffeners, and integrated fuel inlets. The material selected was Inconel 939, suitable for 980–1050°C operating temperatures.

Manufacturing Workflow

Design for Additive: Integrated 1 mm cooling passages, 0.7 mm lattice walls, and optimized chamber contour

SLS Build: Layer thickness 50 μm, build time 38 hours, dimensional tolerance ±0.08 mm

HIP Treatment: 1200°C, 100 MPa for 4 hours to reach 99.8% density

EDM Finishing: Spark erosion of nozzle ports and sealing flanges with ±0.005 mm tolerance

Coating: Applied thermal barrier coating to inner walls

Post-Processing & Inspection

CMM verification of all functional features

X-ray inspection showed no shrinkage or pore clusters

SEM analysis confirmed uniform grain fusion

Ultrasonic immersion testing validated internal integrity

Results and Verification

The final Inconel 939 combustor segment achieved dimensional precision within ±0.08 mm and a finished Ra ≤ 0.6 μm on sealing zones.

All internal cooling paths were clear with measured wall thickness variation below ±0.05 mm after EDM refinement.

X-ray and ultrasonic testing confirmed >99.8% density with no subsurface defects or layer delamination.

The part endured 1000-hour high-pressure hot gas testing with zero distortion or fatigue cracking.

FAQs

What types of superalloys are best suited for SLS-printed combustor parts?

How is porosity addressed in SLS turbine combustion components?

Can film cooling channels be directly printed and post-processed using EDM?

What is the maximum wall thickness achievable for SLS combustion hardware?

What post-treatment is needed for aerospace certification of SLS parts?