Superalloy Deep Core Machining Components Manufacturing Service

High-Integrity Core Machining for Complex Components

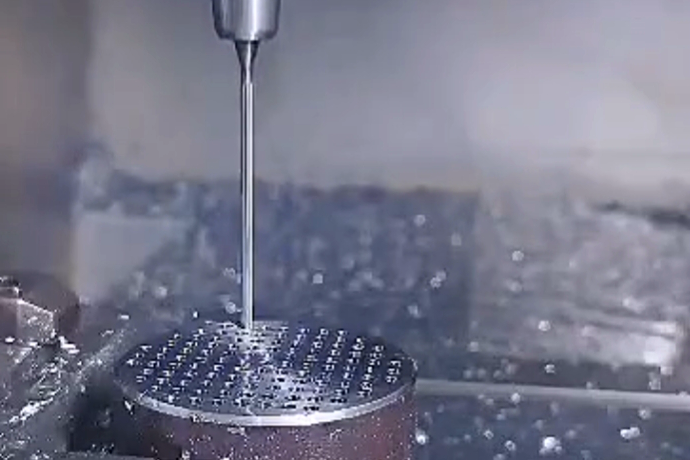

Deep core machined features are fundamental to aerospace turbines, heat exchangers, fuel injection systems, and pressure equipment. These cores often extend into geometrically complex and structurally dense superalloy parts, requiring machining depths of over 20×D with high concentricity, clean internal transitions, and thermally stable finishes.

Neway AeroTech offers end-to-end superalloy CNC machining and deep hole drilling for core-featured components using high-performance materials such as Inconel 718, CMSX-4, Rene 41, and Hastelloy X.

Core Technologies for Superalloy Deep Core Features

Deep core features demand simultaneous control of tool deflection, heat dissipation, and geometry verification.

Gun drilling and BTA boring for through-cores over 500 mm depth

5-axis CNC machining for inlet and outlet transition regions

EDM machining to refine sharp radius internal corners

3D bore mapping and coordinate inspection to track exit location and deviation

Precision fixturing and pre-machining simulation prevent distortion or drift in complex structural components.

Superalloys Used in Deep Core Components

Alloy | Max Temp (°C) | Yield Strength (MPa) | Application |

|---|---|---|---|

704 | 1035 | Engine housings, combustor liners | |

1140 | 980 | Turbine blades, thermal shields | |

980 | 950 | Missile structures, aerospace frames | |

1175 | 790 | Reactor vessels, pressure manifolds |

These alloys are selected for durability under thermal cycling, pressure fluctuation, and corrosive exposure.

Case Study: CMSX-4 Deep Core Cooled Turbine Segment

Project Background

An aerospace client required a 400 mm CMSX-4 turbine segment with internal coolant cores up to 12 mm in diameter and 22×D in depth. Surface finish Ra ≤ 0.5 μm, concentricity ≤ 0.008 mm. A hybrid of deep hole drilling and EDM finishing was applied.

Typical Deep Core Component Models and Applications

Model | Description | Material | Depth Ratio | Industry |

|---|---|---|---|---|

TCS-580 | Turbine core segment with dual 25×D bores | CMSX-4 | 25×D | |

HEV-310 | Heat exchanger vessel with stepped core channels | Inconel 718 | 23×D | |

RPC-600 | Reactor pressure casing with longitudinal bores | Hastelloy X | 20×D | |

MSC-400 | Missile casing core with angled intersecting channels | Rene 41 | 21×D |

Geometry, flow path design, and thermal resistance are all validated by simulation and inspection.

Deep Core Machining Challenges

Concentricity under 0.008 mm through walls over 400 mm thick

Intersection quality in cores with multi-angle cross-bores

Thermal deflection in CMSX and Rene during deep drilling

Recast layer and surface integrity in deep EDM core paths

Material stress release affecting final part flatness post-machining

Solutions for CNC and EDM Machined Core Components

100 bar coolant-fed gun drilling with tool runout control

3+2 axis boring and interpolation for inlet-outlet passage blending

Post-drill EDM polishing to Ra ≤ 0.4 μm

HIP and stress-relief heat treatment to eliminate residual stress

Results and Verification

Manufacturing Methods

Parts began as vacuum castings or precision forgings. Cores were drilled using BTA systems with live-monitoring spindle feedback. Bore depth exceeded 22×D with ±0.01 mm tolerance over 300+ mm.

Precision Finishing

Cores were refined using EDM and brush-lapping tools. Bore roundness <0.006 mm, Ra ≤ 0.4 μm. Intersecting passage burrs were removed using orbital deburring.

Post-Processing

HIP was conducted at 1030°C, followed by heat treatment and surface passivation. TBC coatings were applied selectively for turbine and combustor applications.

Inspection

CMM inspection confirmed bore paths, diameters, and entry angles. X-ray testing validated intersection clearance. SEM ensured recast layers were within specification.

FAQs

What core diameters and depths are supported in superalloy parts?

Can multiple intersecting channels be machined in one operation?

How do you ensure bore alignment across thick-walled components?

Which materials offer the best performance in heat exchanger cores?

What non-destructive tests validate core accuracy and integrity?