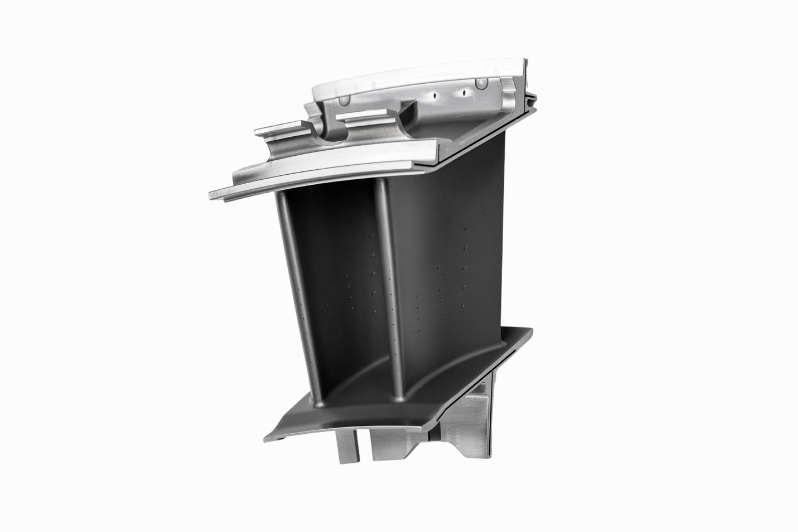

Inconel 718 Superalloy Directional Casting Turbine Vane Parts

Introduction

Turbine vanes are crucial in regulating hot gas flow within gas turbines, requiring exceptional thermal fatigue resistance, dimensional stability, and oxidation tolerance. Inconel 718 is a precipitation-hardened nickel-iron superalloy known for its high strength, weldability, and corrosion resistance. When manufactured using directional casting, Inconel 718 vanes exhibit enhanced creep resistance and fatigue performance due to columnar grain alignment.

Neway AeroTech offers vacuum investment casting of Inconel 718 turbine vane parts using controlled directional solidification technology, serving aerospace, power generation, and marine turbine manufacturers worldwide.

Core Technology of Directional Casting for Inconel 718 Vanes

Wax Pattern Fabrication High-precision wax patterns are produced to replicate vane geometries, including cooling slots and attachment platforms, with ±0.05 mm tolerance.

Shell Mold Construction Refractory ceramic shells (6–8 mm thick) are built using slurry and stucco layering to withstand high temperatures and directional solidification loads.

Grain Selector Integration Spiral grain selectors are built into the mold base to initiate [001] directional grain growth along the vane length, reducing transverse grain boundaries.

Vacuum Induction Melting Inconel 718 alloy is melted under vacuum (≤10⁻³ Pa) at approximately 1380–1420°C to minimize oxidation and segregation.

Directional Solidification The mold is lowered through a controlled thermal gradient at 2–4 mm/min, promoting columnar grain formation from base to tip.

Shell Removal and Surface Cleaning Ceramic molds are removed by high-pressure blasting and leaching, preserving vane features and edge integrity.

Hot Isostatic Pressing (HIP) HIP processing at 1175°C and 150 MPa eliminates residual porosity and improves mechanical properties.

Heat Treatment A tailored solution and aging heat treatment stabilizes the γ″ and γ′ phases for peak high-temperature strength and phase uniformity.

Inconel 718 Material Properties in Directional Casting

Maximum Operating Temperature: 700–750°C

Tensile Strength: ≥1240 MPa at room temperature

Creep Resistance: Maintains ≥180 MPa at 650°C for 1000 hours

Yield Strength: ≥1030 MPa

Fatigue Strength: Excellent under thermal cycling

Grain Orientation: Columnar grains aligned along [001] direction

Case Study: Directionally Cast Inconel 718 Vanes for Industrial Gas Turbines

Project Background

Neway AeroTech was contracted to manufacture first-stage turbine vanes using Inconel 718 for a 60 MW gas turbine. The client required long-term creep resistance, dimensional accuracy, and zero-defect quality for parts operating continuously above 700°C.

Common Applications

Power Generation Turbines (e.g., Siemens SGT, GE 6FA): Directionally cast vanes enhance fatigue and creep resistance under base-load operation.

Aeroengine Guide Vanes (e.g., CF6, LEAP): Vanes with tight geometrical tolerances and fatigue stability in high-thrust environments.

Marine Gas Turbines (e.g., LM2500): Turbine vanes designed for resistance to corrosion and thermal cycling in coastal and naval operations.

Manufacturing Solution for Inconel 718 Directional Cast Vanes

Wax Pattern and Gating Design Patterns and gating systems are optimized using CFD simulation to minimize turbulence, reduce segregation, and promote unidirectional solidification.

Vacuum Casting Execution Inconel 718 alloy is poured into ceramic molds under vacuum, with directional solidification initiated through grain selectors and chill plates.

HIP and Heat Treatment HIP removes micro-voids, followed by heat treatment to optimize γ″/γ′ strengthening and microstructural uniformity.

CNC and EDM Finalization Critical faces, bolt holes, and cooling passages are machined using CNC and EDM to final tolerances.

Inspection and Quality Assurance All vanes undergo X-ray, ultrasonic, and CMM inspection to confirm internal soundness and dimensional precision.

Key Challenges in Casting Inconel 718 Vanes

Preventing segregation and porosity in thick-root or cooling channel regions

Managing withdrawal rate to maintain uniform directional grain growth

Controlling microstructure and avoiding grain coarsening in the airfoil

Maintaining cooling slot precision during casting and post-processing

Results and Verification

Directionally aligned [001] columnar grain structure confirmed via EBSD

HIP removed 100% of detectable internal porosity

Heat treatment resulted in stable γ″/γ′ phase distribution

Mechanical properties exceeded 1240 MPa tensile and 180 MPa creep benchmarks

Final vane dimensions held within ±0.03 mm across full batch production

FAQs

What are the advantages of directional casting for Inconel 718 turbine vanes?

How does Inconel 718 perform compared to other superalloys?

What quality inspections are required for turbine vane certification?

Can directional casting be applied to large vane segments or multi-stage assemblies?

What industries commonly use Inconel 718 directional cast vanes?