High-Depth Superalloy CNC Machined Drilling Components

Extreme-Depth Drilling for Advanced Applications

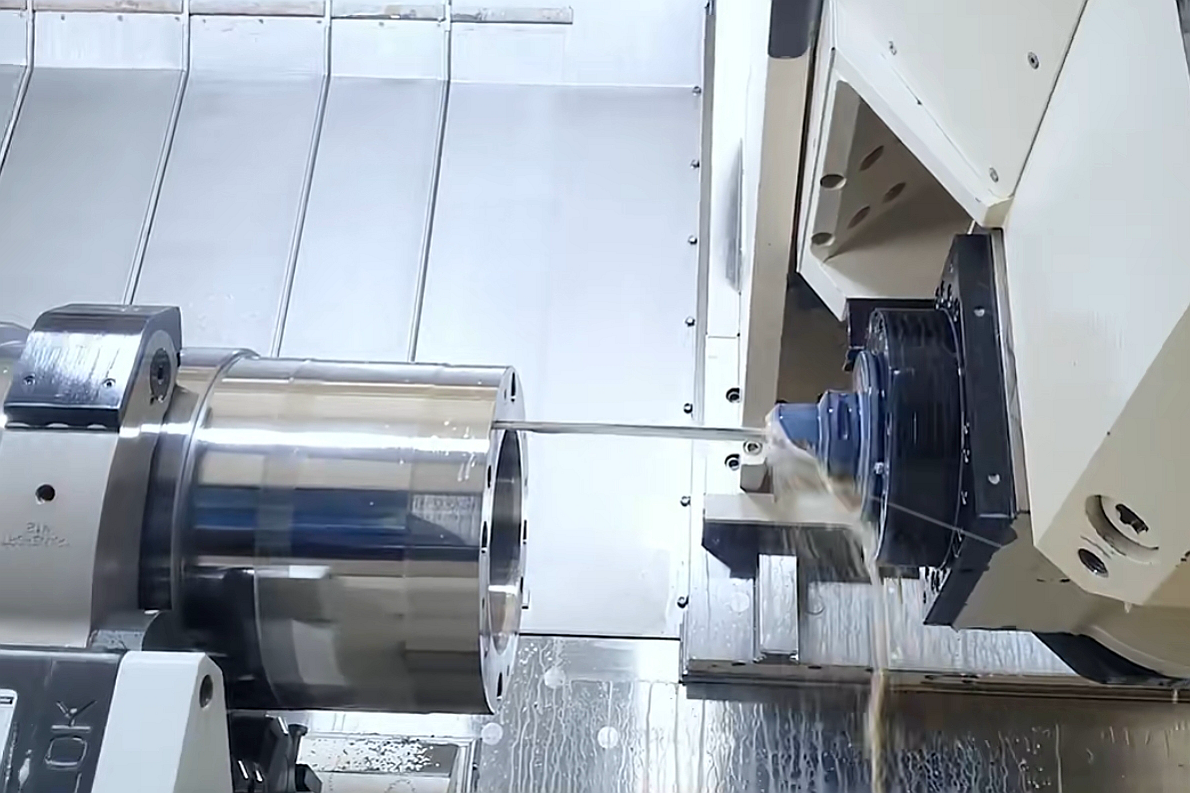

In critical aerospace, energy, and defense systems, components with high-depth drilled features play a key role in coolant distribution, fuel injection, and structural venting. These bores often exceed 25×D, requiring precise superalloy CNC machining and deep hole drilling processes to ensure structural integrity under extreme thermal and mechanical loads.

Neway AeroTech specializes in long-depth CNC-drilled components made from Inconel 718, CMSX-4, Hastelloy X, and Rene 41 with precision bores, counterbores, and angled channels.

Core Technology for Deep CNC Drilling in Superalloys

Deep hole features in superalloys require tool stability, thermal control, and real-time monitoring to prevent deviation.

Gun drilling and BTA boring for hole depths >25×D with internal cooling

5-axis CNC machining for angled entry features

Rotary and peck drilling strategies to control chip evacuation

Coolant-fed carbide tooling rated for 1000°C cutting conditions

All processes are controlled to ISO 10791 and NADCAP standards.

Typical Superalloy Materials for High-Depth Drilling

Alloy | Max Temp (°C) | Yield Strength (MPa) | Use Case |

|---|---|---|---|

704 | 1035 | Jet engine vent tubes | |

1140 | 980 | Turbine liner bores | |

980 | 950 | Missile pressure bodies | |

1175 | 790 | Heat-resistant ducts |

These alloys are optimized for thermal fatigue, creep resistance, and dimensional stability.

Case Study: 26×D Bore in Hastelloy X Pipe Housing

Project Background

A nuclear customer required a straight-through bore 5 mm in diameter, 130 mm in depth (26×D) in Hastelloy X. Tolerances: roundness <0.007 mm, surface finish Ra ≤ 0.4 μm, no burrs or cracks. Chip evacuation and thermal deflection were the primary concerns.

Typical Deep Drilled Component Models and Applications

Part Model | Description | Material | Depth Ratio | Industry |

|---|---|---|---|---|

DHC-600 | Injector sleeve with 2 mm bore over 55 mm | Inconel 718 | 27×D | |

LHP-480 | Heat pipe shell with concentric dual bores | Rene 41 | 25×D | |

FTV-200 | Film cooling channel in single crystal base | CMSX-4 | 30×D | |

HXD-350 | Pressure header with axial and cross bores | Hastelloy X | 26×D |

Bore geometry and cooling flow performance depend on accurate alignment and smooth internal finish.

Deep Drilling CNC Challenges in Superalloy Components

Tool deflection over 0.02 mm in holes >25×D

Heat buildup above 500°C without internal coolant control

Chip accumulation leads to scoring and dimensional taper

Workpiece distortion in thin-walled sections post-drilling

Entry misalignment affects downstream intersecting channels

CNC Machining Solutions for Long Hole Superalloy Drilling

BTA systems with 100 bar coolant pressure and real-time torque sensors

Peck cycle optimization to flush chips every 2×D increment

Multi-axis machining to align angled ports within ±0.01 mm

Heat treatment before and after machining to relieve residual stress

Results and Verification

Manufacturing Methods

Components were machined from forged blanks or investment castings. Gun drilling was applied on Inconel, Rene, and Hastelloy to achieve holes with depth-to-diameter ratios exceeding 25:1.

Precision Finishing

Bores were refined with polishing heads and EDM finishing where applicable. Surface finish ≤ Ra 0.4 μm. Final bore diameter accuracy ±0.01 mm. Entry faces were CNC faced to flatness <0.01 mm for sealing surfaces.

Post-Processing

HIP treatment was used to eliminate internal voids, followed by stress-relief heat treatment at 900–980°C. Select components received passivation or TBC coatings depending on end-use application.

Inspection

CMM verified concentricity and bore alignment within 0.006 mm. X-ray confirmed continuous bore depth and exit point. SEM used for micro crack detection and burr-free validation.

FAQs

What’s the longest bore depth achievable with superalloy CNC machining?

How do you prevent tool deflection in deep holes?

Can EDM be used for bore correction or exit cleanup?

How are bore dimensions verified internally without destructive testing?

What alloys are best for deep-hole aerospace fuel passages?