Corrax (CX) On-Demand Custom Automotive Parts 3D Printing

Introduction to Corrax Stainless Tool Steel for Automotive 3D Printing

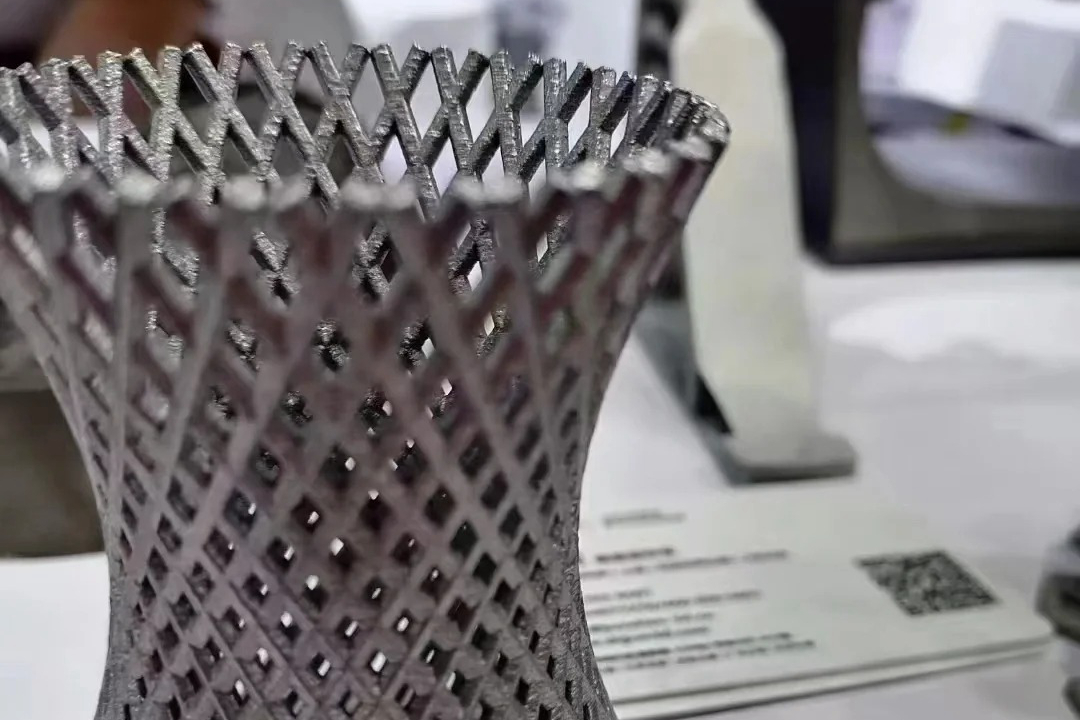

Corrax (CX) is a precipitation-hardened stainless tool steel known for its high strength, corrosion resistance, and excellent polishability. Its dimensional stability and performance after age hardening make it well-suited for automotive molds, die inserts, brackets, and performance components that require precision and durability.

At Neway Aerotech, our stainless steel 3D printing services enable on-demand manufacturing of custom Corrax parts using Selective Laser Melting (SLM) for optimized automotive tooling and end-use components with short lead times.

SLM Additive Manufacturing Capabilities for Corrax (CX)

Process Specifications

Parameter | Value | Relevance for Automotive Components |

|---|---|---|

Layer Thickness | 30–50 µm | Supports high detail resolution |

Surface Roughness (as-built) | Ra 8–12 µm | Ideal for molds and contact surfaces |

Hardness After Aging | ~48 HRC | Durable for wear-prone tooling |

Build Atmosphere | Argon | Maintains corrosion and mechanical integrity |

Machinability | Excellent post-aging | Supports post-print drilling and reaming |

Why Corrax is Ideal for Automotive Applications

Property | Value | Automotive Use Case |

|---|---|---|

Tensile Strength | ~1200 MPa (aged) | High-strength brackets and insert components |

Aging Response | Adjustable (H900–H1025) | Tunable for toughness or hardness requirements |

Corrosion Resistance | Comparable to 420 stainless | Suitable for exposed under-hood environments |

Thermal Stability | Excellent | Maintains shape in heated mold tooling |

Polishability | Very high | Suitable for Class A surface molds and housings |

Post-Processing and Finishing Strategy

Heat Treatment: Age hardened at 520–550°C for desired strength and dimensional precision.

CNC Machining: Applied to mounting faces, threaded bores, or parting lines in molds.

Passivation: Improves corrosion resistance for field-deployed components.

Surface Finishing: Polishing or blasting depending on end-use (Class A surfaces or structural use).

Case Study: 3D Printed Corrax Mold Insert for Automotive HVAC Housing Tool

Project Background

An automotive Tier 1 supplier needed a custom injection mold insert for a plastic HVAC housing component with integrated clips and undercuts. The insert required corrosion resistance due to repeated exposure to humid environments and cooling lubricant.

Manufacturing Workflow

Design: Detailed insert model with cooling channels and clip-release features.

Material: Corrax tool steel powder, D50 ~35 µm.

Printing: SLM at 40 µm layer height, 350 W laser, argon shielding.

Post-Processing:

Heat aged at 525°C for 4 hours.

Mating surfaces CNC machined to ±0.01 mm.

Cooling channels reamed and cleaned.

Validation:

CMM inspection of core/cavity geometry.

Tool installed and ran 10,000 injection cycles with zero wear or distortion.

Results and Verification

The Corrax insert reduced mold development time by 50% compared to traditional machining. Surface polish met VDI 3400 Class 12 finish, and the insert maintained form through 200+ hours of production without crack initiation or corrosion signs. Customer expanded use to additional sensor and trim tooling.

FAQs

What’s the difference between Corrax and traditional tool steels like H13 in automotive molds?

Can Corrax 3D printed parts be used in structural applications beyond tooling?

Is Corrax suitable for underhood brackets or vibration-dampened assemblies?

How is aging heat treatment optimized for Corrax strength vs. ductility?

What surface treatments improve polishability and corrosion protection on Corrax prints?