Cobalt-based Alloys

Material Introduction

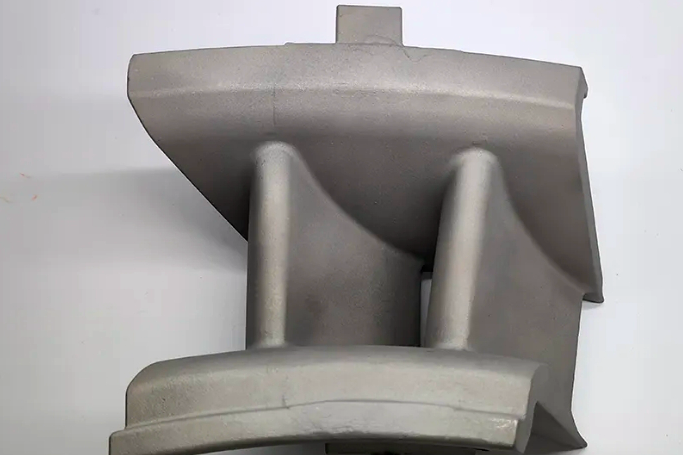

Cobalt-based alloys are a family of high-performance superalloys engineered for extreme temperature, wear, and corrosion environments, making them ideal for precision cobalt-based equiaxed crystal casting components. With a cobalt-rich matrix strengthened by chromium, tungsten, molybdenum, carbon, and other alloying elements, these materials offer outstanding hot hardness, thermal fatigue resistance, and exceptional resistance to metal-to-metal wear and high-temperature oxidation. When combined with Neway AeroTech’s advanced superalloy parts manufacturing capabilities, cobalt-based alloys can be cast into complex equiaxed structures with stable grain morphology, tight dimensional control, and robust integrity. This makes them especially suitable for stationary gas turbine components, hot-section hardware, valve seats, pump wear rings, and sliding or impact-loaded parts operating in aggressive media. Through precise process control, optimized gating design, and tailored heat treatment, Neway AeroTech consistently delivers cobalt-based castings with reliable performance in demanding aerospace, energy, and industrial applications.

Alternative Material Options

When operating conditions or design requirements fall outside the ideal window for cobalt-based alloys, alternative materials can be selected according to temperature, corrosion, and cost constraints. For high-temperature rotating blades, combustor hardware, and turbine discs that demand higher creep strength and lower density, nickel-based alloys such as nickel-chromium equiaxed alloys or advanced casting superalloys provide excellent alternatives. In corrosive chemical or marine environments, Monel alloys or Hastelloy alloys offer superior resistance to acids, chlorides, and reducing media. Where both high-temperature strength and oxidation resistance are critical, Inconel alloys are a common choice for turbine and furnace components. For weight-sensitive applications in aerospace structures or rotating elements, high-strength titanium alloys can significantly reduce mass while maintaining mechanical performance. In scenarios where sliding wear is less severe and cost efficiency is the priority, wear-resistant casting steels from special alloy casting may be preferred.

International Equivalent / Comparable Grade

Country/Region | Equivalent / Comparable Grade | Specific Commercial Brands | Notes |

International (UNS) | R30006 / R30075 / R30188 | Co–Cr–W (Stellite-type), Co–Cr–Mo (F75-type), Haynes 188 | Typical UNS designations for cobalt-based wear- and heat-resistant alloys. |

USA (ASTM/ASME) | ASTM F75, ASTM A494 Co alloys | ASTM F75 Co–Cr–Mo, A494 CW-6M, A494 HF | Widely used for medical, valve, and high-temperature casting components. |

Europe (EN) | CoCr28Mo6, CoCr29W9 | EN CoCr28Mo6 implant alloys, CoCrW wear alloys | European designations for cobalt–chromium–molybdenum and cobalt–chromium–tungsten alloys. |

Germany (DIN) | DIN CoCrMo / CoCrW cast grades | DIN CoCr28Mo6, CoCr29W9-based foundry alloys | Commonly used in power generation and valve components. |

China (GB/T) | CoCrMo / CoCrW casting alloys | Domestic Co–Cr–Mo implant alloys, Co–Cr–W wear alloys | Chinese industry alloys aligned with ASTM F75 and EN CoCr28Mo6. |

Japan (JIS) | JIS cobalt–chromium casting alloys | Co–Cr dental and industrial wear-resisting cobalt alloys | Used for hot-section parts, dental and precision industrial castings. |

ISO | ISO 5832-4 (Co–Cr–Mo casting) | ISO Co–Cr–Mo alloys for medical and structural applications | Defines chemistry and mechanical properties for cobalt-based cast implants. |

Commercial Brand Families | Stellite, Haynes, Tribaloy | Stellite alloys, Haynes 188, Tribaloy series | Representative families of cobalt-based wear and heat-resistant alloys. |

Design Purpose

Cobalt-based alloys for equiaxed crystal casting were developed to deliver reliable strength, wear resistance, and corrosion stability at temperatures where conventional steels and many nickel alloys rapidly degrade. Their design philosophy focuses on maintaining hardness and microstructural stability under thermal cycling, sliding or impact wear, and exposure to oxidizing or carburizing atmospheres. Chromium and tungsten (or molybdenum) provide robust solid-solution strengthening and form protective oxides, while carefully controlled carbon and carbide-forming elements create a finely distributed carbide network that resists adhesive and abrasive wear. In equiaxed casting, the grain structure is optimized to minimize hot cracking and casting defects while providing isotropic properties for non-directional load paths. Working with Neway AeroTech’s equiaxed crystal casting platform, these alloys target mission-critical components, such as valve trims, turbine hot-section parts, sealing surfaces, and tooling inserts, that must withstand long-term service in harsh chemical, steam, or combustion conditions.

Chemical Composition

Element | Cobalt (Co) | Chromium (Cr) | Tungsten (W) / Molybdenum (Mo) | Nickel (Ni) | Carbon (C) | Others (Si, Mn, Fe, etc.) |

Composition (%) | Balance (~55–65) | 25–30 | W 4–7 and/or Mo 0–3 | 0–5 | 0.3–1.4 | Each typically <2.0; impurities tightly controlled |

Physical Properties

Property | Density | Melting Range | Thermal Conductivity | Electrical Conductivity | Thermal Expansion |

Value | ~8.3–8.7 g/cm³ | ~1300–1400°C | ~14–20 W/m·K | ~3–5% IACS | ~13–15 µm/m·°C (20–800°C) |

Mechanical Properties

Property | Tensile Strength (Room Temp.) | Yield Strength (Room Temp.) | Elongation | Hardness | High-Temperature Strength |

Value | ~650–900 MPa | ~400–650 MPa | ~1–6% | ~320–480 HB (≈ 32–48 HRC) | Retains significant strength up to ~800–900°C |

Key Material Characteristics

Excellent high-temperature wear resistance for sliding, galling, and erosive environments, even at elevated temperatures.

Excellent oxidation and hot corrosion resistance in combustion gases, steam, and chemical process atmospheres.

Stable hardness and microstructure under thermal cycling, reducing softening and distortion over long-term service.

Good castability in equiaxed cobalt-based alloy casting, allowing for the creation of complex shapes with a controlled grain structure.

The carbide-reinforced microstructure provides excellent resistance to adhesive and abrasive wear under boundary lubrication conditions.

High compressive strength and edge stability for sealing surfaces, valve seats, and cutting or forming tools.

Robust performance under combined mechanical, thermal, and chemical loading, particularly in power generation and oil and gas environments.

Good compatibility with downstream heat treatment and hot isostatic pressing to improve toughness and reduce porosity.

Resistant to sulfidation and carburization in aggressive combustion or furnace atmospheres.

Capable of long service life where downtime costs are high and reliability is critical.

Manufacturability And Post Process

Equiaxed crystal casting: Primary route for cobalt-based alloys; suitable for complex stationary parts, valve trims, and wear blocks.

Special alloy casting: Supports tailored compositions and near-net-shape designs for high-volume industrial components.

Hot Isostatic Pressing (HIP): Reduces internal porosity, improves fatigue and creep resistance for critical rotating or pressure-containing parts.

Heat treatment: Solution and aging cycles refine carbides, stabilize microstructure, and balance hardness with toughness.

Superalloy CNC machining: Used to achieve tight tolerances and precision sealing surfaces; requires rigid tooling, optimized feeds and speeds.

Electrical Discharge Machining (EDM): Ideal for intricate features, sharp corners, and difficult-to-machine geometries in hardened cobalt alloys.

Superalloy deep hole drilling: Enables cooling channels and long, accurate bores in thick-walled valves and turbine hardware.

Superalloy welding: Supports repair of worn surfaces and addition of cobalt-based hardfacing layers on critical regions.

Material testing and analysis: Ensures chemistry, microstructure, and mechanical properties meet stringent aerospace and energy standards.

Typical post-process steps include precision grinding, lapping, honing, and shot peening to achieve required surface finish and fatigue performance.

Suitable Surface Treatment

Thermal Barrier Coating (TBC): Applied to hot-section cobalt alloy parts to reduce metal temperature and extend service life.

Carbide-based hardfacing overlays: Further enhance wear resistance for valve seats, sealing faces, and cutting edges.

Shot peening: Introduces compressive residual stresses to improve fatigue strength and resistance to crack initiation.

Precision grinding and lapping: Achieve low roughness (e.g., Ra ≤ 0.4–0.8 µm) on sealing and bearing surfaces.

Polishing: Used on medical or hygienic components to minimize crevice corrosion and fouling.

Specialized diffusion or oxidation treatments: Improve scale adhesion and high-temperature oxidation behavior in aggressive environments.

Surface inspection and non-destructive testing, supported by material testing and analysis, verify coating integrity and bond quality.

Common Industries and Applications

Power generation: Stationary gas turbine vanes, combustor tiles, transition ducts, and wear pads exposed to hot gas and steam.

Oil and gas: Valve seats, choke beans, pump wear rings, and sliding components in erosive, corrosive multiphase flow.

Chemical processing: Components in corrosive and high-temperature reactors, furnaces, and process control valves.

Aerospace and aviation: Hot-section hardware, guide vanes, and wear-resistant fittings operating under severe thermal cycles.

Nuclear: Components requiring radiation resistance, corrosion resistance, and long-term stability at elevated temperatures.

Marine and mining: Wear-resistant parts in pumps, dredging systems, and abrasive slurry handling.

Industrial valves and flow-control hardware: Seat rings, cages, and trim inserts exposed to cavitation, flashing, and particulate erosion.

Tooling and dies: Hot-work inserts, forming dies, and cutting tools where wear and thermal fatigue dominate design.

When to Choose This Material

Severe high-temperature wear: Ideal when components experience simultaneous sliding, impact, or erosion above 500–600°C.

Oxidizing and corrosive atmospheres: Recommended for hot gas, steam, or chemical environments where steels scale or corrode rapidly.

Demanding reliability: Suitable for critical power or process equipment where unplanned downtime and failures are unacceptable.

High contact stress applications: Preferred for valve seats, bearings, and sealing interfaces requiring high hardness and edge stability.

Thermal cycling conditions: Performs well where components are repeatedly heated and cooled, limiting crack initiation and propagation.

Long service life requirements: Justified where lifecycle cost and maintenance intervals outweigh initial material cost.

Complex equiaxed castings: A strong choice when equiaxed cobalt alloy casting enables near-net shapes with minimal machining.

Mixed wear and corrosion mechanisms: Effective where both chemical attack and mechanical wear act simultaneously on the same surfaces.