Ti-6.5Al-1Mo-1V-2Zr (TA15) Titanium Selective Laser Melting (SLM) 3D Printing

Introduction to TA15 Titanium Alloy Additive Manufacturing

TA15 (Ti-6.5Al-1Mo-1V-2Zr) is a near-α titanium alloy developed for high strength, excellent creep resistance, and superior weldability. With SLM 3D printing, TA15 enables the fabrication of lightweight, high-performance aerospace and structural components with complex geometries.

At Neway Aerotech, our SLM titanium 3D printing services deliver precision TA15 components optimized for aircraft, energy, and defense-grade applications.

SLM Technology for TA15 Titanium Alloy

Process Capabilities and Parameters

Parameter | Value | Description |

|---|---|---|

Layer Thickness | 30–50 μm | Fine resolution for complex aerospace geometries |

Build Chamber Atmosphere | Inert Argon | Prevents oxidation and alpha case formation |

Laser Power | 200–400 W | Optimized for uniform fusion and minimal porosity |

Relative Density | ≥ 99.5% | Ensures structural integrity |

Heat Treatment | Anneal @ 800–850°C | Refines microstructure and reduces residual stress |

TA15 Material Properties and Performance

Property | Value | Relevance in Application |

|---|---|---|

Ultimate Tensile Strength | 1100–1200 MPa | High load capacity in aerospace frames |

Yield Strength | ~1000 MPa | Structural support under dynamic stress |

Density | 4.48 g/cm³ | Lightweight compared to steels or nickel alloys |

Fatigue Limit (R=0.1) | ~550 MPa | Long service life in cycling environments |

Operating Temperature | Up to 500°C | Thermal stability for engine and airframe parts |

Why Choose TA15 for Additive Manufacturing

TA15 combines near-α alloy strength with good weldability, making it ideal for SLM 3D printing.

Its creep resistance and low oxygen sensitivity ensure stability during high-altitude and thermal fluctuation conditions.

Unlike Ti-6Al-4V, TA15 offers improved high-temperature strength and is widely used in high-speed aircraft and rocket structures.

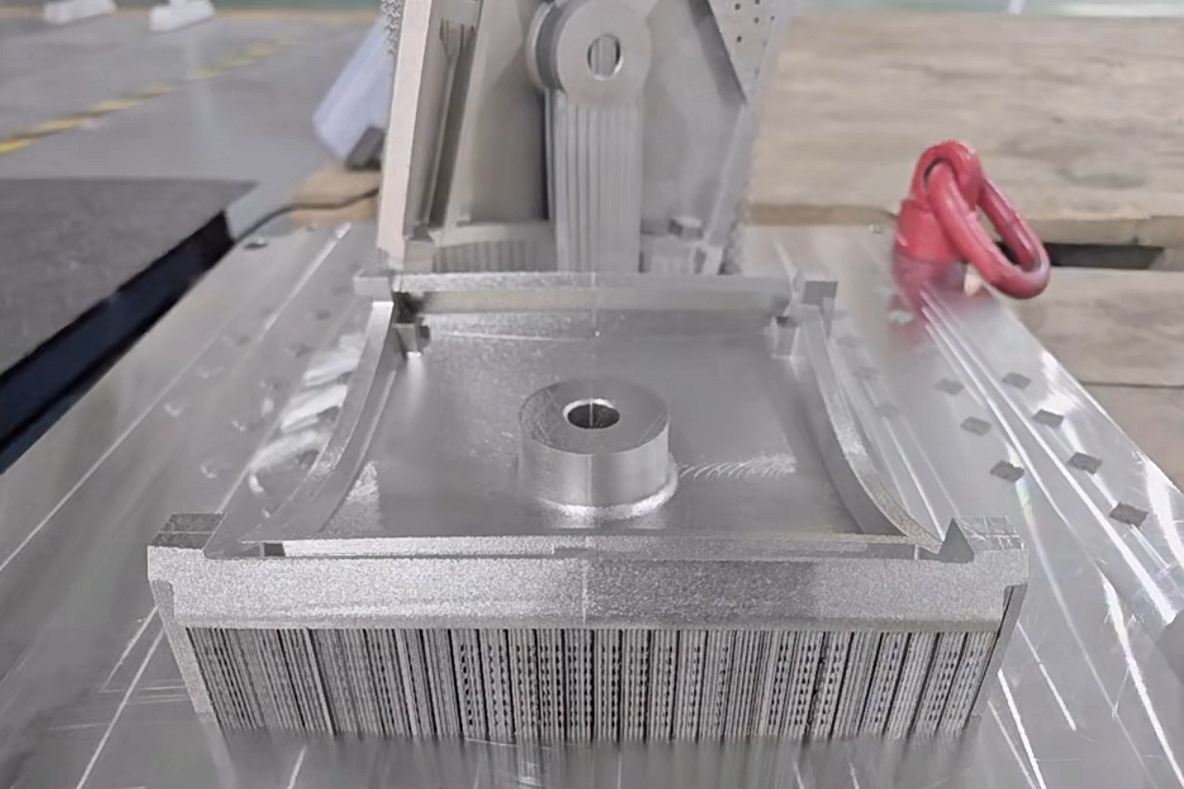

Case Study: TA15 SLM 3D Printed Truss Support Bracket for Aerospace Airframe

Project Background

An aerospace OEM required a high-strength, lightweight truss support bracket optimized for topology and weight reduction. The bracket needed to withstand 40 kN axial load at 480°C, with geometric constraints not suitable for machining.

Manufacturing Workflow

Design: Topology optimized geometry imported in STL; minimum wall thickness 1.2 mm; fillets and radii >1 mm for fusion reliability.

Material: TA15 titanium powder, D50 ~35 µm, argon atomized.

Printing Process: SLM at 40 µm layers, 350 W laser, argon atmosphere, 200 mm/s scan speed.

Post Processing: HIP at 920°C / 100 MPa for 2 hours; annealed at 830°C for stress relief.

Machining & Fitting: Mounting holes and flange surfaces finished via 5-axis CNC to ±0.01 mm tolerance.

Surface Finishing & Inspection

Ra reduced from 14 μm to 3 μm via micro blasting and mechanical polishing.

CMM inspection confirmed geometric accuracy within ±0.02 mm.

X-ray CT scan detected no internal porosity or fusion defects.

Fatigue tested to 10⁷ cycles at 500 MPa with no failure.

Results and Verification

The SLM-printed TA15 bracket achieved a 38% weight reduction over forged aluminum equivalent and passed both tensile (1150 MPa) and fatigue (10⁷ cycles) tests. The customer approved production for flight hardware following qualification in simulated altitude and thermal load conditions.

FAQs

How does TA15 compare to Ti-6Al-4V in mechanical and thermal performance?

What is the recommended post-process heat treatment for SLM printed TA15 parts?

Can TA15 be used in structural aerospace components with safety-critical loads?

How fine can internal lattice structures be printed with TA15 using SLM?

What surface finishing is best for improving fatigue life in TA15 printed components?