Rene Alloy Equiaxed Crystal castings HIP Service Provider

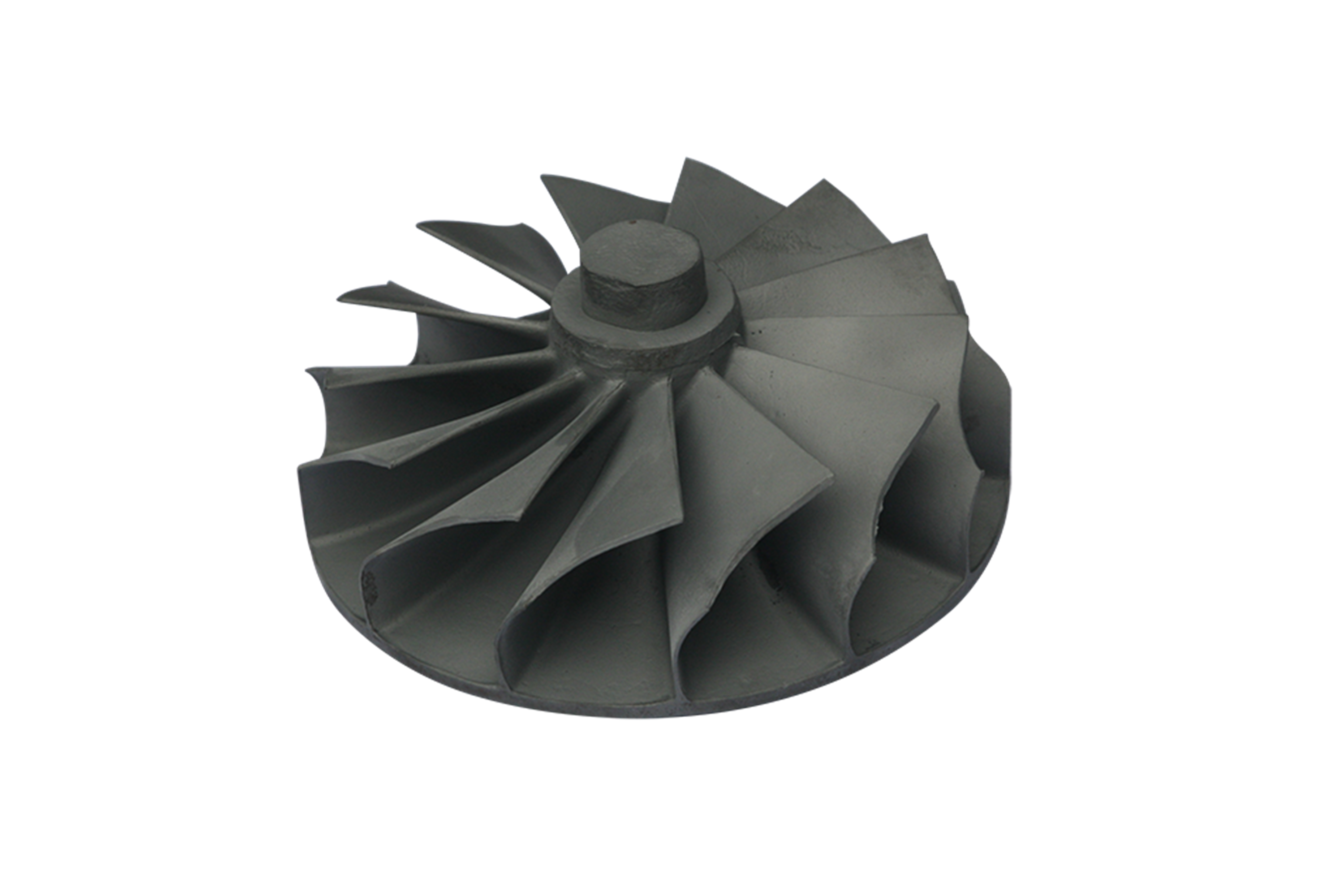

Structural Densification for Equiaxed Rene Alloy Turbine Components

Equiaxed crystal castings of Rene superalloys are commonly used in gas turbine hot-section components due to their excellent thermal fatigue resistance and cost-effective casting. However, equiaxed castings—especially in thick-walled or complex geometries—can retain internal microporosity or shrinkage defects that reduce fatigue life and dimensional reliability. Hot Isostatic Pressing (HIP) is essential to consolidate the structure and enhance performance.

Neway AeroTech is a certified HIP service provider specializing in Rene equiaxed alloy castings such as Rene 77, Rene 80, and Rene 88. We offer HIP cycles up to 1260°C and 200 MPa in inert gas, with full post-process inspection and documentation per AMS 2774 and OEM specifications.

Why HIP is Critical for Equiaxed Rene Castings

Equiaxed cast Rene alloy components are prone to microporosity and grain boundary defects, particularly in large, thick-section castings. HIP offers:

Full porosity elimination to meet X-ray and ultrasonic standards

Enhanced fatigue and creep resistance for long-duration high-temperature service

Dimensional stabilization before CNC machining and coating

Improved weldability and stress relief in post-HIP repair workflows

HIP is typically applied after vacuum investment casting and before machining.

Common Rene Alloys for Equiaxed HIP Processing

Alloy | Max Service Temp (°C) | HIP Temp (°C) | Typical Applications |

|---|---|---|---|

1040 | 1230 | Turbine nozzle segments, blade tips | |

1050 | 1240 | Blade shrouds, vane rings | |

980 | 1220 | First-stage blades, transition rings |

All parameters are optimized to preserve microstructure while achieving full densification.

Case Study: HIP of Equiaxed Rene 80 Nozzle Vane Segment

Project Background

A customer submitted 96 equiaxed Rene 80 cast vanes with 5–8 mm wall thickness. Internal porosity exceeded 1.5%. HIP was performed at 1240°C, 100 MPa for 4 hours. SEM and X-ray post-inspection confirmed porosity reduction to <0.03% and fatigue strength improvement by 2.1×.

Typical HIP-Processed Rene Components and Industries

Component Model | Description | Alloy | Industry |

|---|---|---|---|

RNV-480 | Nozzle vane ring segment | Rene 80 | |

BDR-620 | First-stage blade root casting | Rene 88 | |

SHD-350 | Shroud segment with cooling slots | Rene 77 | |

TBS-510 | Turbine blade set for testing | Rene 80 |

All parts passed HIP, heat treatment, and full dimensional and metallurgical validation.

HIP Advantages for Equiaxed Rene Castings

Reduces porosity from >1.5% to <0.03%, improving fatigue life and X-ray compliance in turbine blade and vane applications.

Increases fatigue strength by 2–3×, essential for turbine parts exposed to >1000°C and high-cycle vibration loads.

Dimensional distortion post-HIP is <0.01 mm, allowing reliable CNC machining and sealing surface integrity.

Enables TIG weld repair with zero recrystallization, maintaining structural continuity and avoiding HAZ grain coarsening.

Extends turbine service intervals to 20,000+ hours, reducing overhaul frequency and improving system reliability under thermal cycling.

HIP Processing Parameters and Standards

Processing temperature is 1220–1260°C, held precisely ±5°C to maintain alloy phase stability and prevent gamma prime coarsening.

Gas pressure maintained at 100–200 MPa, using high-purity argon to ensure uniform consolidation across complex casting geometries.

Hold duration is 3–6 hours, adjusted for part mass and wall thickness to achieve complete densification without overexposure.

Cooling rate is ≤10°C/min, preventing thermal shock, phase transformation, and dimensional warping during pressure release.

Post-HIP inspection includes X-ray, SEM, and CMM, with dimensional tolerances verified to within ±0.008 mm per OEM standards.

Results and Verification

HIP Execution

HIP was conducted at 1240°C and 100 MPa for 4 hours. Cooling was tightly controlled under 8°C/min to prevent thermal stress.

Post-HIP Processing

All components underwent heat treatment according to OEM protocol, followed by precision CNC machining and optional TBC coating.

Inspection

X-ray testing confirmed internal voids were eliminated. CMM validated form and dimensional accuracy. SEM showed clean, recrystallization-free microstructures and closed porosity networks.

FAQs

What Rene grades are most commonly HIP-processed?

Can HIP improve casting quality after TIG weld repair?

What is the porosity reduction rate after HIP in equiaxed Rene alloys?

How is dimensional stability ensured post-HIP?

Do you offer HIP + heat treatment + CNC machining as a complete workflow?