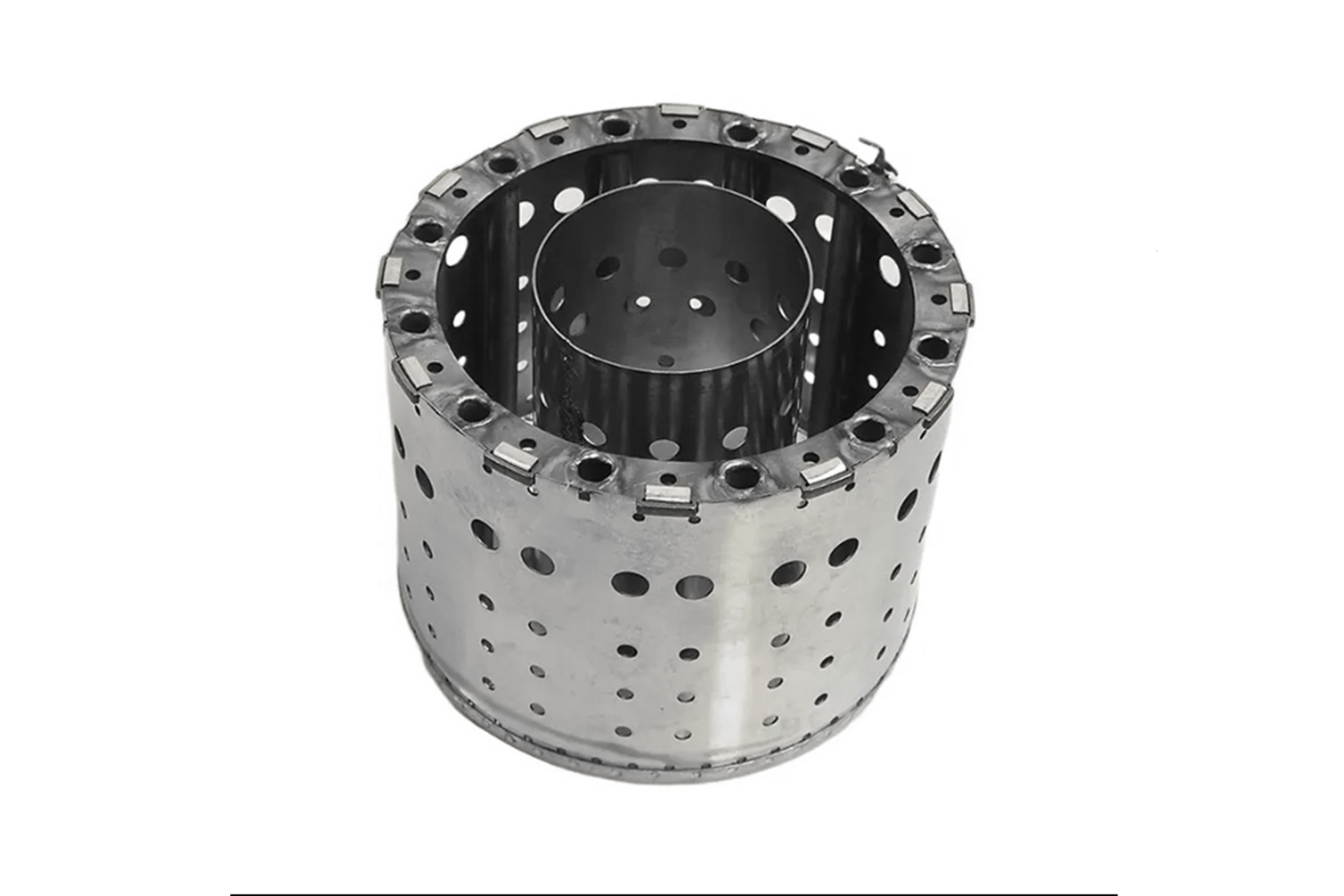

Rene 41 Vacuum Investment Casting Aerospace Exhaust Systems Manufacturer

Introduction

Rene 41 is a high-performance nickel-based superalloy developed for extreme heat environments, offering exceptional tensile strength, oxidation resistance, and creep resistance up to 1100°C. As an experienced vacuum investment casting manufacturer, we supply Rene 41 components for aerospace exhaust systems with dimensional precision of ±0.05 mm and porosity under 1%.

Our castings are ideal for aerospace propulsion and exhaust systems, where mechanical integrity, thermal stability, and long-term oxidation resistance are critical.

Core Technology: Vacuum Investment Casting of Rene 41

We utilize vacuum investment casting to produce Rene 41 components, ensuring structural integrity and oxidation resistance. The alloy is vacuum melted and poured at ~1400°C into ceramic shell molds preheated to ~1050°C. Controlled solidification (cooling rate: 30–80°C/min) promotes refined equiaxed grain structures (0.5–2 mm) and dimensional accuracy within ±0.05 mm.

Material Characteristics of Rene 41 Alloy

Rene 41 is a precipitation-strengthened nickel-based superalloy designed for high-stress, high-temperature aerospace environments. It offers excellent mechanical properties and oxidation resistance at elevated service temperatures. Key characteristics include:

Property | Value |

|---|---|

Density | 8.36 g/cm³ |

Ultimate Tensile Strength (at 815°C) | ≥1240 MPa |

Yield Strength (at 815°C) | ≥1035 MPa |

Elongation | ≥12% |

Creep Rupture Strength (1000h @ 982°C) | ≥190 MPa |

Operating Temperature Limit | Up to 1100°C |

Oxidation Resistance | Excellent |

Rene 41 maintains dimensional and mechanical stability in exhaust ducts, transition zones, and nozzle assemblies under continuous thermal and gas exposure.

Case Study: Aerospace Exhaust Component Production

Project Background

An aerospace engine OEM required cast Rene 41 nozzle segments and ducting for a high-bypass turbofan engine exhaust system. Our team produced vacuum-cast parts conforming to AMS 5545 and customer specifications, incorporating HIP and precision machining for sealing surfaces and flange interfaces.

Typical Exhaust System Applications

Turbofan Engine Nozzle Segments (e.g., PW1000G, CFM LEAP): Rene 41 segments withstand hot exhaust flow and thermal cycling while maintaining dimensional accuracy and oxidation protection.

Afterburner Transition Ducts: High-temperature ducting components operating in transient thermal environments in military jet exhaust systems.

Thrust Reverser Structural Elements: Cast Rene 41 components subjected to stress reversal and dynamic heating during deceleration and landing.

Exhaust Liner Supports and Hinge Arms: Lightweight structural supports for liner assemblies exposed to direct turbine exhaust gases.

These applications require thermal fatigue resistance, low thermal expansion mismatch, and long service durability in high-cycle exhaust environments.

Manufacturing Solutions for Rene 41 Exhaust Parts

Casting Process Wax patterns are assembled and invested into ceramic molds. The alloy is vacuum melted and cast at ~1400°C, with controlled cooling to prevent hot tearing and segregation. The process yields consistent dimensional accuracy and internal soundness.

Post-processing Hot Isostatic Pressing (HIP) is performed at 1190°C and 100 MPa to remove internal porosity and improve fatigue performance. Solution aging treatments are applied to optimize precipitation hardening for high-temperature strength.

Post Machining Critical surfaces are finished using CNC machining for bolt holes, sealing edges, and duct interfaces. EDM is used for thin cross-sections, and deep hole drilling creates access ports or internal cooling holes.

Surface Treatment Parts can be treated with thermal barrier coatings (TBC) or aluminide coatings to protect against oxidation, thermal fatigue, and gas erosion.

Testing and Inspection Each casting is inspected with X-ray radiography, CMM dimensional analysis, mechanical testing at elevated temperatures, and metallographic inspection for phase consistency and grain integrity.

Core Manufacturing Challenges

Avoiding hot tearing and shrinkage in large, thin-wall exhaust segments.

Maintaining phase stability and oxidation resistance above 1000°C.

Meeting tight tolerance requirements in duct interfaces and bolted assemblies.

Results and Verification

Dimensional accuracy within ±0.05 mm validated by 3D CMM scanning.

Porosity <1% confirmed via post-HIP X-ray inspection.

Creep rupture strength ≥190 MPa at 982°C verified by long-duration stress testing.

No grain degradation or surface oxidation after 1000-hour thermal exposure at 1100°C.

FAQs

Why is Rene 41 the preferred alloy for aerospace exhaust system castings?

How does vacuum casting improve the quality of Rene 41 components?

What heat treatments are required for Rene 41 to achieve high-temperature strength?

Can Rene 41 castings be customized for specific exhaust geometries?

What inspection processes ensure aerospace compliance for Rene 41 exhaust parts?