Precision Aluminum 3D Printing with Advanced SLM and LMD Technologies

Introduction to High-Precision Aluminum Additive Manufacturing

Aluminum alloys are favored across aerospace, automotive, energy, and industrial sectors for their lightweight strength, excellent thermal conductivity, and corrosion resistance. With advanced 3D printing methods—namely Selective Laser Melting (SLM) and Laser Metal Deposition (LMD)—precision aluminum components can now be manufactured with intricate geometries, tight tolerances, and significantly reduced lead times.

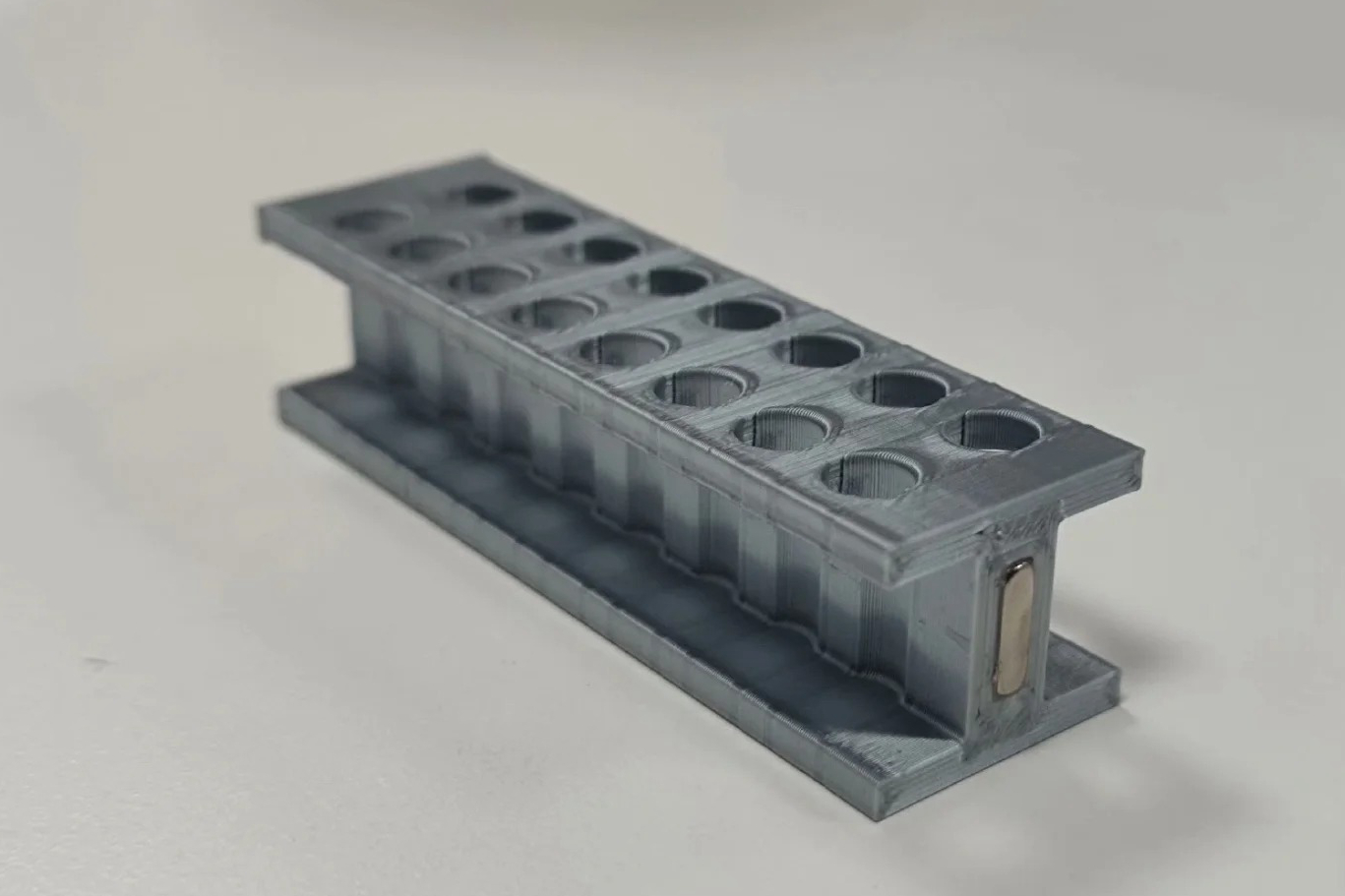

At Neway Aerotech, our aluminum 3D printing services integrate both SLM and LMD technologies to deliver optimized components for performance-critical applications such as heat exchangers, housings, brackets, and structural frames.

Additive Manufacturing Technologies: SLM vs. LMD

Process Comparison

Parameter | SLM (Selective Laser Melting) | LMD (Laser Metal Deposition) |

|---|---|---|

Layer Thickness | 30–50 μm | 300–800 μm |

Feature Accuracy | ±0.05 mm | ±0.2 mm |

Surface Roughness (Ra) | 8–15 μm | 10–25 μm |

Build Size | ≤ 300 × 300 × 400 mm | Up to 1000 mm (multi-axis possible) |

Applications | Lightweight brackets, housings | Structural repairs, large profiles |

SLM excels in fine-feature builds and high-resolution prototypes, while LMD is ideal for larger, low-porosity structures and component repair.

Aluminum Alloys Used in SLM and LMD Printing

Alloy | Strength (MPa) | Characteristics | Applications |

|---|---|---|---|

AlSi10Mg | 320–370 | High stiffness, excellent printability | Aerospace brackets, UAV frames, engine parts |

AlSi7Mg | 280–320 | Better elongation, good surface finish | Heat sinks, enclosures, structural elements |

AlSc-based Alloys | 400–500 | High strength, fine grain structure | Motorsports, satellite, high-performance frames |

Why Choose Aluminum SLM and LMD Technologies

Dimensional Accuracy: Ideal for tolerance-critical features like sealing interfaces, heat exchanger cores, and housings.

Lightweight Efficiency: Enables part consolidation and topological optimization, cutting up to 50% weight.

Rapid Turnaround: Ideal for development timelines where tooling is infeasible.

Post-Process Compatibility: Easily machined, anodized, and joined with other metals.

Scalability: LMD supports large-format parts, hybrid repairs, or cladding applications.

Post-Processing Strategy

Stress Relief & Heat Treatment: 300–350°C for 2 hours for AlSi10Mg to improve mechanical stability.

HIP: Optional for improved fatigue performance in high-cycle aerospace components.

CNC Machining: Used for interfaces, threads, and sealing features.

Anodizing: Adds corrosion resistance and color coding for assemblies.

Case Study: Aluminum SLM-Manufactured Satellite Electronics Housing

Project Background

A commercial space client required a high-strength, weight-optimized aluminum housing for avionics with EMI shielding ribs, integrated fastening bosses, and internal cooling fins. Traditional CNC approaches were over budget and incompatible with internal channel designs.

Manufacturing Workflow

Material: AlSi10Mg, gas-atomized powder, D50 ~35 μm.

Process: SLM printing at 40 μm layer height, build time: 9 hours.

Post-Processing:

Heat treated at 320°C.

Machined mounting faces and connector ports to ±0.01 mm.

Surface anodized for durability and thermal reflection.

Inspection: CMM inspection and CT scanning validated all internal structures.

Results and Verification

The SLM-produced housing achieved a 46% weight reduction and integrated five features that previously required machining and assembly. All dimensions passed tolerance checks, and vibration and thermal shock testing validated the housing for space qualification.

FAQs

What is the difference between SLM and LMD for aluminum 3D printed parts?

Can internal channels and cooling fins be printed in aluminum?

What aluminum alloys are available for 3D printing at Neway Aerotech?

What finishing options are available for appearance and corrosion resistance?

Are both small and large aluminum parts printable with these technologies?