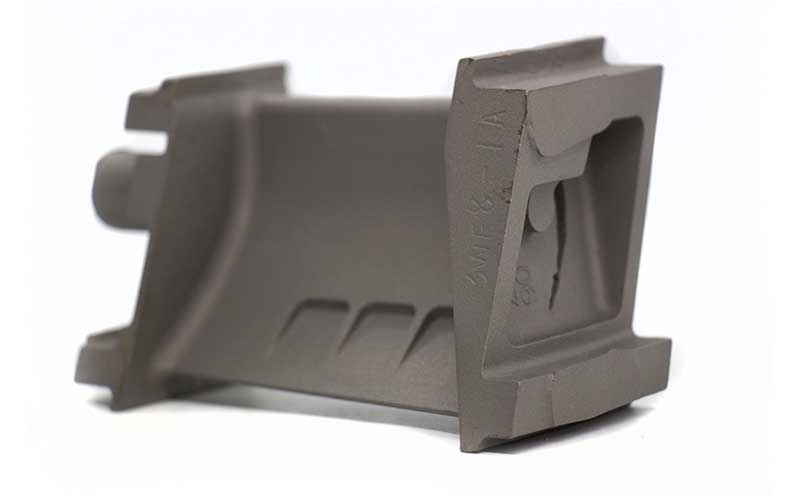

Nimonic 115 Precision Casting Aerospace Engine Vane Parts Factory

Introduction

Nimonic 115 is a nickel-chromium-cobalt-based superalloy developed for use in advanced aerospace engines, offering outstanding high-temperature strength, oxidation resistance, and creep resistance up to 1040°C. At our specialized precision casting factory, we manufacture Nimonic 115 vane components with ±0.05 mm dimensional tolerance, low porosity (<1%), and refined grain structure, ensuring optimal performance in critical jet engine environments.

Our parts are built to meet the rigorous thermal and mechanical demands of modern aerospace and aviation turbine systems.

Core Technology: Precision Investment Casting of Nimonic 115

Our Nimonic 115 components are produced using high-precision ceramic shell investment casting under vacuum, with alloy melting around 1420°C and mold preheating at 1050–1100°C. Controlled solidification rates of 40–90°C/min produce uniform equiaxed grains (0.5–2 mm), low shrinkage, and consistent porosity below 1%. This method supports tight geometrical control and ensures compliance with critical turbine specifications.

Material Characteristics of Nimonic 115 Alloy

Nimonic 115 is a nickel-based wrought/cast alloy strengthened by γ' (gamma prime) precipitation and solid-solution hardening, offering high thermal fatigue resistance. It’s ideal for advanced turbine vanes in high-thrust jet engines. Key properties include:

Property | Value |

|---|---|

Melting Range | 1345–1390°C |

Density | 8.3 g/cm³ |

Tensile Strength (at 950°C) | ≥940 MPa |

Yield Strength (at 950°C) | ≥670 MPa |

Creep Rupture Strength (1000h @ 950°C) | ≥180 MPa |

Elongation | ≥12% |

Oxidation Resistance | Excellent up to 1040°C |

These properties enable Nimonic 115 to maintain integrity and reliability under continuous thermal cycling and hot gas exposure.

Case Study: Nimonic 115 Aerospace Engine Vane Parts

Project Background

A Tier 1 aerospace engine manufacturer required high-performance stator vanes for a next-generation turbofan engine operating in high-pressure and high-temperature zones (up to 1040°C). Our factory supplied precision-cast Nimonic 115 vanes meeting AMS 5824 and ISO 9001 standards, optimized for aerodynamic profile control and high-cycle fatigue endurance.

Typical Aerospace Engine Vane Applications

HPT Guide Vanes (e.g., LEAP, PW1100G): Used in the first turbine stage to direct exhaust flow at 1000+°C, where creep and oxidation resistance are essential.

Afterburner Vanes (e.g., F414, EJ200): Operate under thermal shock and fluctuating loads; Nimonic 115 provides structural stability and metallurgical reliability.

Intermediate Pressure Vanes (e.g., Trent 7000): Face prolonged cyclic thermal conditions, requiring low-porosity castings and uniform γ' distribution.

Advanced VSV Assemblies: Integrated into variable stator vane systems with precise wall thickness and fatigue resistance.

These components are vital for optimizing airflow, combustion efficiency, and durability in modern jet propulsion systems.

Vane Component Manufacturing Solutions

Casting Process Investment casting under vacuum ensures metallurgical cleanliness. Wax patterns are molded into 8–10-layer ceramic shells. Alloy is vacuum poured at ~1420°C, and solidification is controlled to ensure fine grain structure and high casting yield.

Post-processing Castings undergo Hot Isostatic Pressing (HIP) at 1180°C and 100 MPa to reduce porosity and enhance fatigue life. Final CNC machining ensures edge profiles, mounting flanges, and cooling passages meet strict tolerance standards.

Surface Treatment Thermal Barrier Coatings (TBC), typically 7–8% yttria-stabilized zirconia (YSZ), are plasma-sprayed to insulate vanes from extreme gas temperatures, reducing surface metal temperatures by up to 200°C.

Testing and Inspection Every part undergoes X-ray inspection, CMM validation, and tensile testing at elevated temperatures. Metallographic microscopy ensures proper phase distribution and grain structure control.

Core Manufacturing Challenges of Engine Vane Components

Casting thin-wall geometries with tight tolerances (±0.05 mm) while avoiding hot tearing and segregation.

Controlling γ' distribution and carbide precipitation to ensure fatigue resistance and uniform mechanical strength.

Maintaining surface integrity suitable for coating adhesion and aerodynamic efficiency.

Results and Verification

Our delivered Nimonic 115 vane components achieved:

Porosity <1% and uniform equiaxed grains (0.5–2 mm), verified by X-ray and metallographic testing.

Dimensional accuracy of ±0.05 mm confirmed via 3D CMM analysis.

High-temperature strength above 940 MPa at 950°C, validated through destructive and non-destructive testing.

Excellent coating adhesion and oxidation resistance after 1000-hour exposure testing at 1040°C.

FAQs

What makes Nimonic 115 ideal for aerospace turbine vane applications?

How is casting precision maintained in thin-wall Nimonic 115 components?

What post-processing treatments improve Nimonic 115 fatigue life?

Can Nimonic 115 vanes be customized for specific OEM engine models?

What testing procedures ensure mechanical and metallurgical compliance?