Material Testing and Analysis for High-Temperature Alloy Parts Integrity

Ensuring Structural Soundness Under Extreme Thermal and Mechanical Loads

Components manufactured from high-temperature alloys such as Inconel, Rene, CMSX, and Hastelloy are used in turbine engines, nuclear systems, and chemical reactors. These components must maintain integrity in environments exceeding 1000°C, where oxidation, creep, thermal fatigue, and microstructural instability can compromise performance. Comprehensive material testing and analysis is critical to ensure that parts meet safety, durability, and performance standards.

Neway AeroTech offers a full suite of destructive and non-destructive testing (NDT) services for high-temperature alloys, including microstructural characterization, mechanical testing, chemical composition analysis, and defect evaluation. Our laboratory capabilities are aligned with aerospace, energy, and nuclear qualification standards.

Key Material Testing Methods for Superalloy Components

Testing methodologies must validate physical properties, chemical composition, and microstructure before and after service or processing.

Tensile testing at elevated temperature for yield, UTS, and elongation

Scanning Electron Microscopy (SEM) for grain boundaries, phase distribution, and crack propagation

CMM inspection for geometric tolerances post-machining or post-HIP

Glow Discharge Mass Spectrometry (GDMS) for bulk chemistry and trace elements

X-ray inspection for porosity, weld integrity, and casting defects

All testing follows ASTM, ISO, and customer-specific OEM standards.

Alloys Commonly Tested for Integrity

Alloy | Max Temp (°C) | Typical Applications | Testing Focus |

|---|---|---|---|

704 | Discs, flanges, nozzles | Tensile, GDMS, CMM | |

980 | Blades, housings | SEM, X-ray, tensile | |

1140 | Airfoils, vanes | SEM, microstructure, creep | |

1175 | Combustor panels | GDMS, SEM, grain size |

Testing ensures microstructural and chemical integrity across as-cast, post-machined, and post-service states.

Case Study: SEM and GDMS on Rene 88 Turbine Blade

Project Background

A turbine blade made from Rene 88 underwent inspection after 3000 service hours at 950°C. SEM analysis identified γ′ coarsening and crack nucleation at grain boundaries. GDMS confirmed no elemental depletion. CMM measured root wear. Blade was classified repairable.

Commonly Analyzed Components and Applications

Component | Alloy | Testing Methods | Industry |

|---|---|---|---|

Turbine Airfoil | CMSX-4 | SEM, tensile | |

Fuel Injector Housing | Hastelloy X | GDMS, X-ray | |

Nozzle Ring | Inconel 718 | Tensile, CMM | |

Blade Shroud | Rene 88 | SEM, creep, GDMS |

Each part is tested based on its function, operating temperature, and stress exposure.

Key Challenges in Superalloy Testing and Analysis

Creep strain measurement at >1000°C requires extensometers with accuracy below ±0.5%

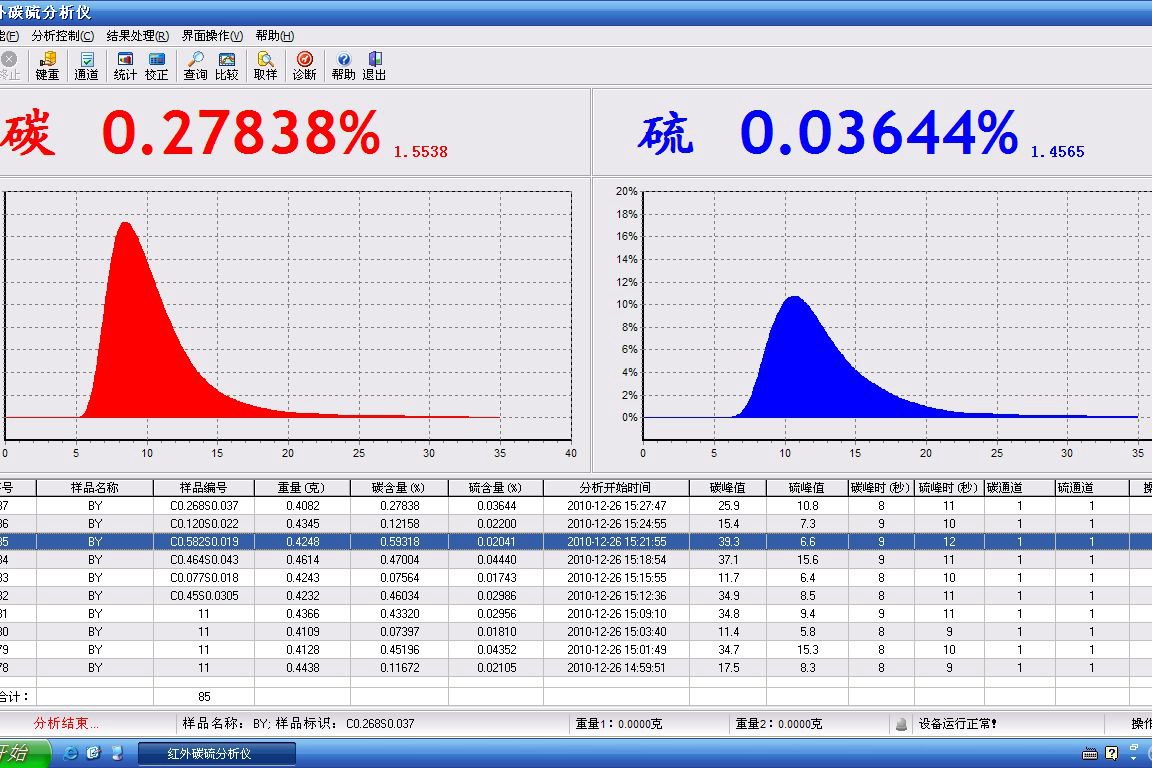

GDMS detection limits <1 ppm critical for residuals like sulfur and oxygen in Hastelloy and CMSX

Microcrack detection <5 μm requires high-magnification SEM and sample prep precision

Component distortion >0.02 mm post-HIP or machining affects CMM accuracy

Phase balance validation between γ and γ′ phases critical for turbine service life

Comprehensive Testing Solutions

High-temperature mechanical frames for tensile and creep up to 1200°C

Argon-purged GDMS analysis for oxidation-sensitive materials

Cryogenic sample prep for brittle fracture surface analysis under SEM

X-ray radiography with digital imaging for porosity mapping

**Automated CMM scanning for features within ±0.005 mm tolerance

Results and Verification

Mechanical Testing

Alloys were tested at service-matched temperatures. Rene 88 parts retained >90% yield strength after simulated 3000-hour thermal aging.

Surface and Dimensional Analysis

CMM and SEM verified dimensional consistency and grain integrity. Cooling holes and root fits were within ±0.01 mm spec.

Chemical Validation

GDMS showed bulk chemistry deviation <0.03 wt.%. Trace elements within OEM tolerances.

Structural Integrity

X-ray confirmed no internal cracking or pore clusters. SEM confirmed <12% porosity and phase uniformity.

FAQs

What testing is essential for post-HIP verification of cast turbine parts?

How is γ′ phase distribution evaluated in CMSX alloys?

What role does GDMS play in high-temperature alloy QA?

Can you assess distortion after machining or coating?

Are your test results qualified to aerospace and nuclear standards?