Inconel Vacuum Investment Casting Turbine Components Welding Service

High-Performance Welding for Cast Inconel Turbine Parts

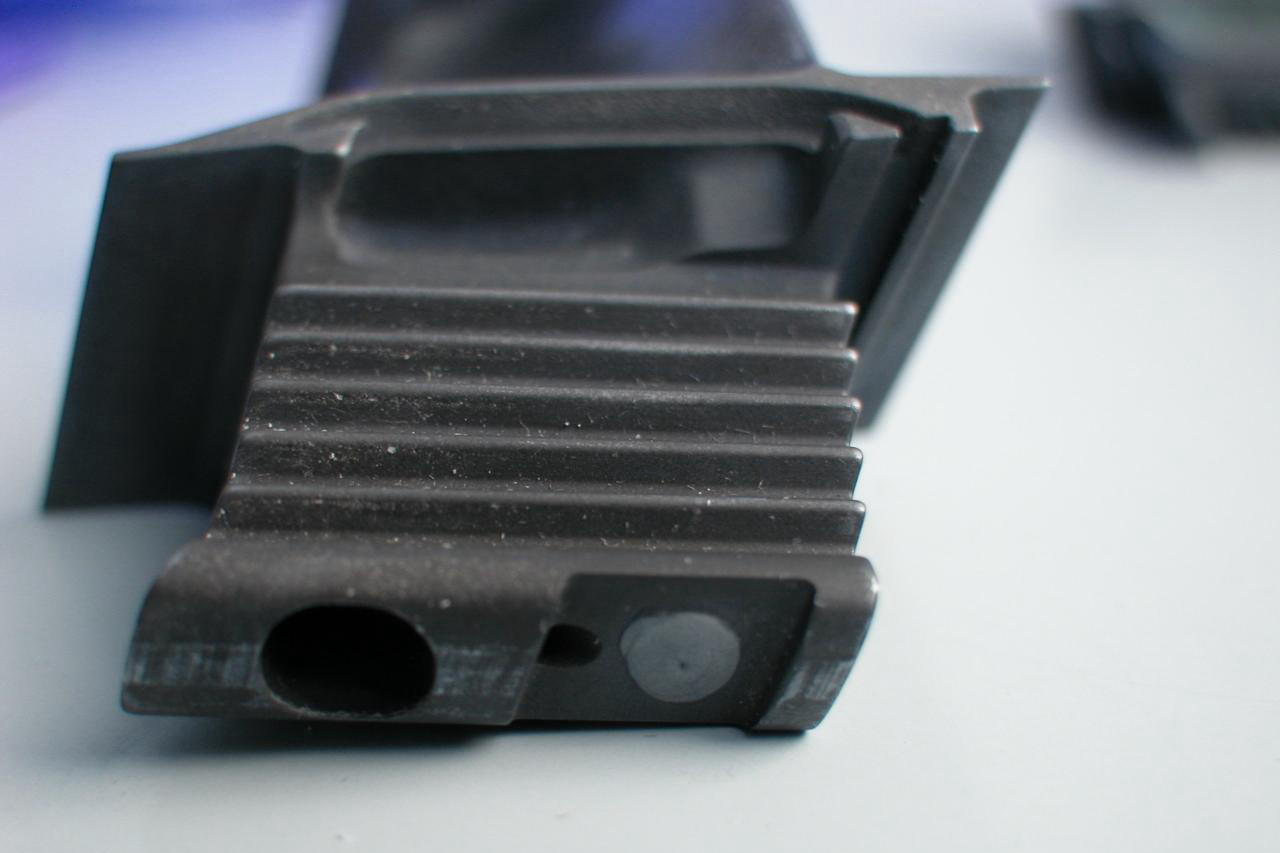

Inconel turbine components produced via vacuum investment casting are engineered to endure extreme thermal loads and corrosive environments. However, their complex geometries often require post-casting joining, repair, or modification. Welding Inconel alloys demands precise control to prevent microcracking, distortion, and phase imbalance in the heat-affected zone (HAZ).

Neway AeroTech provides certified superalloy welding services for Inconel turbine blades, vanes, exhaust parts, and structural housings manufactured through vacuum investment casting. Our solutions integrate laser and TIG welding technologies, tailored post-weld heat treatments, and multi-step inspection processes to guarantee mechanical reliability and metallurgical consistency.

Core Welding Technologies for Inconel Turbine Components

Neway AeroTech combines advanced joining processes and metallurgical control to weld complex Inconel turbine geometries.

TIG welding with Inconel 625/718 filler for structural parts

Laser welding for localized, low-distortion joints in thin cast walls

Vacuum welding chamber capability for oxidation-sensitive applications

Pre- and post-weld heat treatment for microstructure homogenization

We maintain NADCAP-compliant processes and AS9100D quality control throughout welding operations.

Common Inconel Grades and Turbine Applications

Grade | Max Temp (°C) | Yield Strength (MPa) | Application |

|---|---|---|---|

704 | 1035 | Turbine blades, nozzle segments | |

980 | 827 | Exhaust cones, support rings | |

950 | 760 | Turbine wheel vanes | |

1050 | 880 | Hot section casings, end caps |

These alloys are frequently joined or repaired after casting due to assembly constraints or post-machining defects.

Case Study: TIG Weld Repair on Inconel 718 Turbine Blade Segment

Project Background

A customer submitted cast Inconel 718 turbine blade segments exhibiting minor tip cracking after finish machining. Weld repair involved localized TIG buildup using matching filler metal, followed by stress relief heat treatment and X-ray inspection. Restored blades met OEM dimensional and metallurgical specs.

Typical Welded Turbine Component Models and Applications

Component | Weld Type | Alloy | Industry |

|---|---|---|---|

Nozzle Segment | TIG, root + cover pass | Inconel 718 | |

Exhaust Cone | Laser perimeter weld | Inconel 625 | |

Blade Tip Extension | TIG buildup | Inconel 713C | |

Hot Section Flange | Vacuum laser weld | Inconel 738 |

Each weld is designed for long-term high-cycle fatigue performance under thermally aggressive conditions.

Welding Challenges in Cast Inconel Turbine Parts

Gamma prime phase instability during welding can cause HAZ cracking

Hot tearing and liquation common in Inconel 713C and 738

Residual stress must be minimized post-weld to avoid distortion

Weld dilution control is critical for corrosion resistance

Inspection access is limited in closed or contoured turbine geometries

Certified Welding Solutions for Inconel Casting Repair and Joining

Automated TIG welding systems for controlled multi-pass welding

Pulse laser welding for minimal HAZ and micro-joining

Post-weld heat treatment to stabilize microstructure

HIP processing available for porosity removal in repaired regions

Surface passivation and TBC coatings for protection in combustion zones

Results and Verification

Welding Execution

Welding was performed using Inconel-specific filler matched to base alloy composition. Pre-weld grinding and fit-up used CMM-aided alignment. Weld zones were built in multi-layer mode, followed by blended contour finishing.

Post-Weld Processing

Stress-relief heat treatment was performed at 980°C to reduce HAZ hardness gradients. Components received HIP where requested, followed by optional coating for thermal resistance.

Inspection

X-ray NDT confirmed no inclusions or voids. CMM verified dimensional recovery. SEM validated grain continuity and microcrack absence. All repairs passed OEM inspection and returned to flight status.

FAQs

What welding processes are suitable for cast Inconel turbine parts?

How do you prevent cracking during Inconel welding?

Can turbine blades be repaired after casting defects?

What inspection methods are used post-welding?

Do you offer HIP and coating after welding?