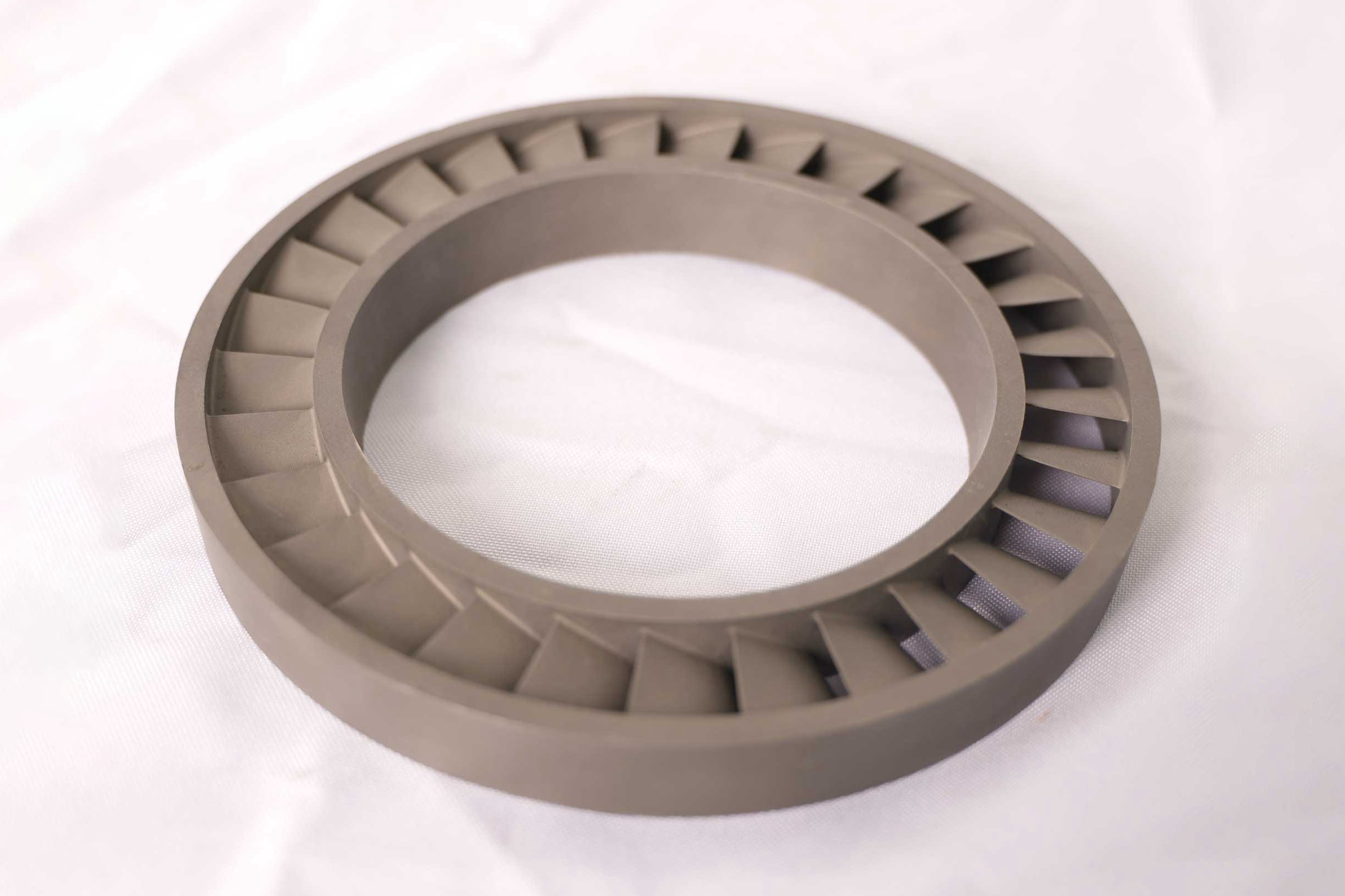

Inconel alloy Precision Forging Turbine Discs and Blades

Introduction

Inconel alloy precision forging enables the production of turbine discs and blades with outstanding mechanical strength, thermal stability, and fatigue resistance. At Neway AeroTech, we utilize this advanced process to forge Inconel 718, 625, and 738 components that operate reliably under extreme stress, high temperatures (up to 750°C), and cyclic loading in aerospace, power generation, and oil and gas sectors.

Precision forging refines the microstructure, eliminates casting defects, and delivers near-net shape turbine components with dimensional tolerances as tight as ±0.02 mm.

Core Technology of Inconel Alloy Precision Forging

Alloy Billet Preparation: High-purity Inconel billets (e.g., 718, 625, 738) are preheated to forging temperatures of 1050–1150°C.

Die Forging Process: Using closed-die forging under controlled deformation rates, the material is shaped with minimal internal stress and superior grain flow.

Microstructure Control: Grain size controlled to ASTM 9–12 with directional alignment, improving fatigue life and mechanical stability.

Solution and Aging Treatment: Post-forging heat treatment cycles optimize phase distribution and achieve tensile strengths above 1200 MPa.

Final Machining: CNC machining achieves surface finishes better than Ra 1.6 µm and dimensional tolerances within ±0.02 mm.

Surface Coating (Optional): Thermal Barrier Coatings (TBC) applied to protect against oxidation and thermal fatigue in turbine applications.

Material Characteristics of Forged Inconel Alloys

Property | Inconel 718 | Inconel 625 | Inconel 738 |

|---|---|---|---|

UTS (at 650°C) | 1240–1380 MPa | 930–1040 MPa | 1130–1250 MPa |

Creep Resistance | Excellent to 700°C | Excellent to 650°C | Superior up to 980°C |

Fatigue Resistance | High-cycle fatigue rated | Excellent under cyclic loads | High thermal fatigue life |

Corrosion Resistance | Excellent (oxidation/chloride) | Outstanding in harsh media | Very good at high temp |

Grain Structure | Controlled, ASTM 9–12 | Controlled, fine grain | Directionally solidified |

Case Study: Forged Inconel Turbine Components for Aeroengine Program

Project Background

A global jet engine OEM required high-performance forged Inconel discs and blades capable of surviving 750°C turbine temperatures and extreme centrifugal loads. Neway AeroTech provided a complete forging-to-finishing solution.

Common Applications and Component Types

High-Pressure Turbine (HPT) Discs: Forged from Inconel 718, offering structural integrity at 15,000+ RPM with fatigue life >30,000 cycles.

Low-Pressure Turbine (LPT) Blades: Inconel 738 forged blades provide thermal fatigue resistance during long flight hours in commercial engines.

Turbomachinery Blades: Forged Inconel 625 blades used in power plant turbines for corrosion resistance in high-humidity exhaust environments.

Compressor Discs: Inconel 718 forged discs ensure tight tolerances and durability in the demanding environment of aerospace compressors.

Manufacturing Solution for Inconel Forged Turbine Parts

Billet Heating: Inconel 718 billets are heated to 1100°C under a protective atmosphere to avoid oxidation during forging.

Precision Closed-Die Forging: Forging presses apply controlled force and strain rate to maintain optimal grain flow and dimensional stability.

Flash Removal and Shaping: Minimal flash trimmed, producing near-net shape parts that reduce machining effort by up to 40%.

Heat Treatment: Solution and aging treatments performed at 980–1150°C to develop phase precipitation and mechanical strength.

Final Machining: Machining conducted on multi-axis CNC platforms ensures tolerances within ±0.02 mm for tight aerodynamic clearances.

Surface Enhancement: TBC coatings applied on blades to minimize oxidation and extend life in hot sections.

Non-Destructive Testing (NDT): X-ray and ultrasonic testing verify internal defect-free integrity for high-reliability aerospace use.

Dimensional Inspection: All critical geometries verified using Coordinate Measuring Machine (CMM).

Manufacturing Challenges and Solutions

Forging high-alloy materials while avoiding grain growth

Achieving complex blade airfoil shapes with minimal post-machining

Maintaining fatigue and creep performance at elevated temperatures

Achieving repeatability in tight-tolerance aerospace geometries

Results and Validation

Mechanical Strength: Forged components achieved tensile strengths >1300 MPa, yield strengths >1000 MPa post-aging.

Fatigue Life: Fatigue tests exceeded 35,000 cycles at 700°C without crack initiation.

Creep Resistance: Creep rupture testing confirmed integrity at 750°C for >10,000 hours.

Surface Finish: Final Ra <1.6 µm achieved through CNC finishing and polishing.

Dimensional Accuracy: All components met geometric tolerance goals within ±0.02 mm across blade profiles and disc bores.

FAQs

What Inconel grades are most commonly forged for turbine discs and blades?

What mechanical advantages does forged Inconel offer over cast alternatives?

How does Neway AeroTech control grain structure in forged turbine components?

Can forged Inconel blades be coated with thermal barrier coatings?

What quality assurance processes are used for forged aerospace turbine parts?