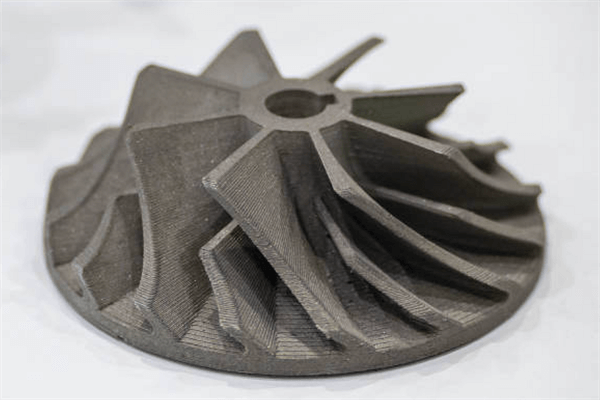

Inconel 718 Superalloy Turbo Charger 3D Printing Additive Manufacturing Supplier

Introduction to 3D Printing Turbocharger Parts in Inconel 718

Inconel 718 is a nickel-based superalloy ideal for turbocharger components operating under extreme thermal and mechanical stress. Additive manufacturing enables the production of intricate, lightweight turbo geometries that cannot be achieved through conventional machining or casting.

At Neway Aerotech, our Inconel 718 3D printing services provide precision turbocharger components with high fatigue resistance, corrosion durability, and thermal performance, serving aerospace, automotive, and energy industries.

Additive Manufacturing Technologies for Turbo Components

Applicable 3D Printing Methods

Technology | Layer Thickness (μm) | Surface Roughness (Ra, μm) | Feature Resolution (mm) | Common Applications |

|---|---|---|---|---|

SLM | 30–50 | 5–15 | ≥0.2 | Turbine housings, impellers, bearing brackets |

DMLS | 40–60 | 6–18 | ≥0.25 | Exhaust volutes, scroll channels, end plates |

SLM is the preferred process for Inconel 718 due to its excellent density control and fine structural detail.

Inconel 718 Performance in Turbocharger Environments

Property | Value | Benefit in Turbo Applications |

|---|---|---|

Yield Strength @ 700°C | ≥ 720 MPa | Maintains structure under high-speed rotor heat loads |

Fatigue Resistance | > 10⁸ cycles @ 650 MPa | Ensures life span in high-vibration, thermal cycling zones |

Oxidation Resistance | Up to 980°C | Suitable for exhaust-facing parts without degradation |

Creep Rupture Resistance | > 1000 hours @ 704°C / 620 MPa | Supports continuous operation under boosted conditions |

Weldability & Printability | Excellent for SLM | Ensures crack-free additive processing and post machining |

Material Selection Justification

Inconel 718 is selected over cast iron or aluminum due to its stability at 700–980°C and fatigue reliability in continuous boost cycles.

Its superior weldability and crack resistance make it well-suited for post-print repair or hybrid assembly.

Fine precipitate strengthening (γ″ and γ′ phases) ensures stability during repeated heating/cooling cycles.

Case Study: 3D Printed Inconel 718 Turbocharger Exhaust Housing

Project Background

A performance automotive client required a lightweight turbo exhaust housing that could withstand 950°C exhaust temperatures and operate continuously at 120,000 rpm. Complex internal scroll geometries and thin-wall cooling channels were essential.

Manufacturing Workflow

Material: Inconel 718 powder with particle size D50 = 35 µm, spherical morphology.

Printing: SLM additive manufacturing with 30 μm layer height, using argon inert atmosphere for oxidation control.

Build Strategy: Internal scroll supported by lattice core; downskin optimization to ensure 45° angle wall overhangs.

Post Processing: Hot Isostatic Pressing at 1200°C/100 MPa for 4 hours to eliminate micro-porosity.

CNC Finishing: Machined sealing flanges to ±0.01 mm flatness and internal bore concentricity within 0.02 mm.

Surface Finishing

Internal surfaces vapor polished to Ra ≤ 6 μm for optimal gas flow.

TBC Coating applied to exterior walls for radiant heat deflection.

Final part passivated to prevent surface oxidation during initial heat cycles.

Inspection & Verification

CMM inspection confirmed dimensional conformity within ±0.03 mm.

X-ray CT scanning detected zero internal delamination.

Ultrasonic testing validated wall density in thin-walled scroll sections.

Flow test passed at 1800 L/min with <1.5% back pressure variance across samples.

Results and Verification

The printed Inconel 718 turbo housing achieved 30% weight reduction over cast version and successfully passed 1000-hour endurance at 950°C. It maintained full dimensional integrity under thermomechanical fatigue and withstood 300,000 turbine revolutions per durability test cycle.

FAQs

What is the maximum operating temperature of Inconel 718 printed turbo parts?

How does Inconel 718 compare to 625 in turbocharger applications?

Can printed turbo components be welded to other materials?

What surface treatments improve oxidation resistance on turbo housings?

Do you offer topology optimization for printed turbocharger designs?