Inconel 625 Superalloy Random Grain Structure Casting Pump and Valve Parts Foundry

Introduction

Pump and valve components used in chemical processing, marine, power generation, and high-temperature fluid systems face severe mechanical loads, corrosive media, and high thermal stress. These components require materials with excellent corrosion resistance, strength, and thermal fatigue endurance. Inconel 625, a solid-solution strengthened nickel-chromium-molybdenum alloy, is ideal for such applications due to its superior resistance to pitting, chloride-induced stress corrosion, and oxidation.

Neway AeroTech is a professional superalloy casting foundry offering Inconel 625 pump and valve parts produced via random grain structure casting. Our vacuum investment casting process ensures dimensional accuracy, isotropic mechanical properties, and outstanding corrosion resistance. We serve industries such as chemical processing, marine systems, and power generation.

Core Technology of Random Grain Casting for Inconel 625 Components

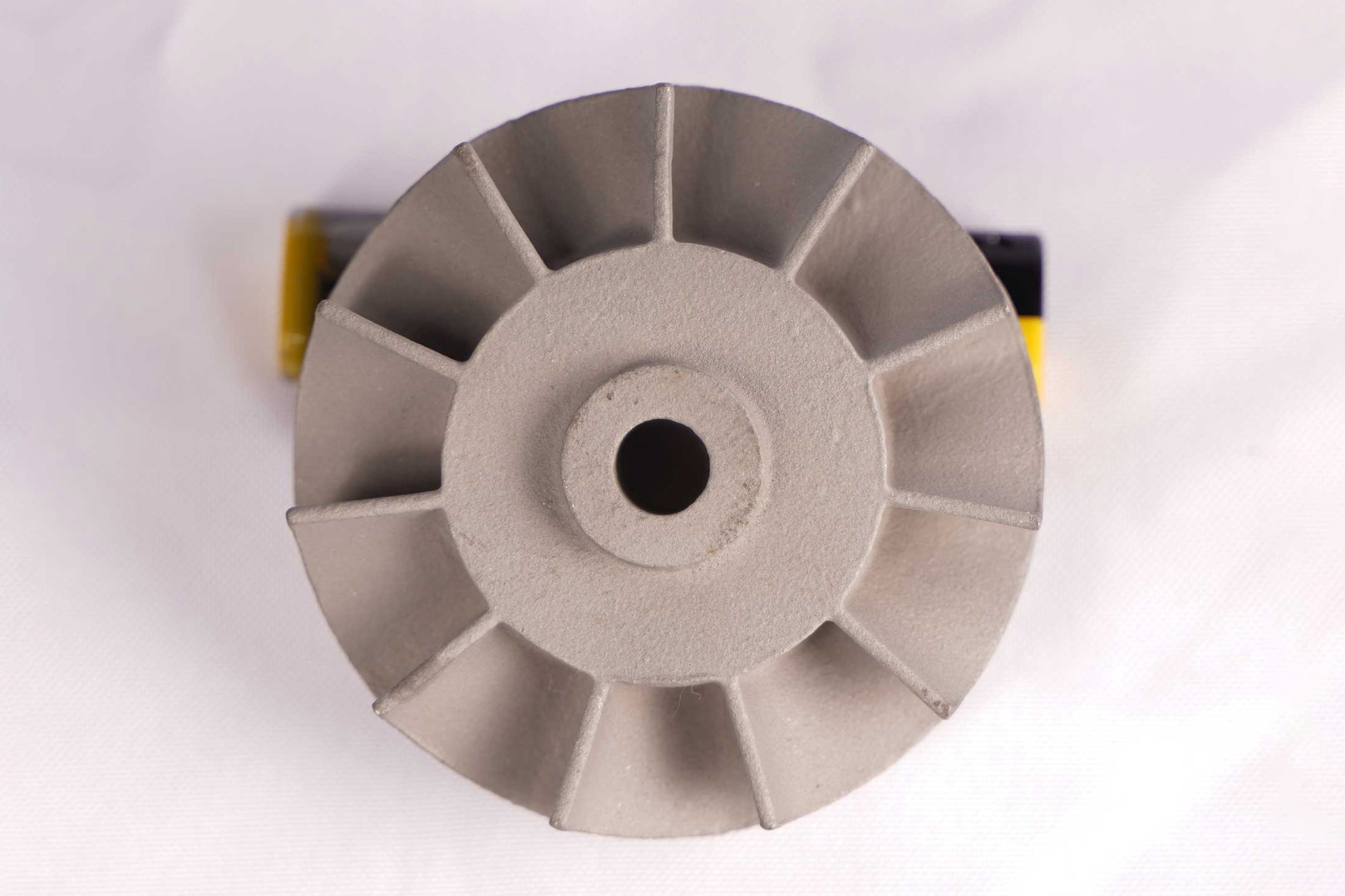

Wax Pattern Development Pump housings, impellers, valve bodies, and flanges are replicated via high-precision wax patterns with ±0.05 mm tolerance.

Ceramic Shell Mold Construction 6–8 mm thick multilayer ceramic shells are applied for high thermal stability and accurate surface replication.

Vacuum Induction Melting Inconel 625 is melted at ~1350–1400°C under vacuum (≤10⁻³ Pa) to ensure purity and minimize oxide formation.

Random Grain Equiaxed Solidification The molten alloy solidifies in preheated molds, producing equiaxed, randomly oriented grains (ASTM 4–6), ensuring uniform mechanical behavior.

Shell Removal and Cleaning Shells are removed by high-pressure blasting and leaching, protecting internal passages and sealing surfaces.

Heat Treatment Solution annealing at 980–1040°C optimizes corrosion resistance and relieves residual stress.

CNC Finishing and EDM Critical surfaces including threaded ports, sealing faces, and valve seats are finalized via CNC machining and EDM.

Inspection and Testing Parts undergo CMM, pressure testing, and X-ray inspection as required for structural integrity.

Inconel 625 Material Properties in Cast Form

Max Service Temperature: ~980°C

Tensile Strength: ≥830 MPa

Yield Strength: ≥414 MPa

Corrosion Resistance: Exceptional against seawater, acids, alkalis, and oxidizing salts

Creep Resistance: Good under moderate temperature/pressure loading

Grain Structure: Equiaxed random grains (ASTM 4–6)

Case Study: Inconel 625 Valve and Pump Parts for Offshore Platform

Project Background

Neway AeroTech manufactured Inconel 625 valve bodies, stems, and pump casings for a deepwater oil and gas platform. The components operated in high-pressure, chloride-rich conditions at 250°C. Requirements included zero leakage, strong resistance to pitting, and structural integrity after prolonged exposure.

Applications

Seawater Circulation Pumps Tolerate aggressive marine environments with high flow rates and cavitation exposure.

Chemical Process Valves Require corrosion resistance in acidic, oxidizing, or alkali-heavy fluids.

Feedwater Pump Bodies Withstand high thermal gradients and pressure in steam cycles and waste heat recovery.

Cryogenic Control Valves Maintain dimensional stability under fluctuating pressure and thermal cycling.

Manufacturing Workflow at Neway AeroTech

Design for Casting (DFC) Our engineering team supports DFM and CFD-backed gating design for optimal mold filling and solidification.

Vacuum Investment Casting Execution Inconel 625 is cast in vacuum-controlled conditions with equiaxed grain formation, ensuring uniform isotropic strength.

Post-Casting Heat Treatment, Annealing, and stress-relieving treatments restore ductility and corrosion performance.

Machining and Assembly Prep CNC turning, milling, threading, and EDM are used to achieve sealing surface quality and dimensional tolerances.

Final Inspection and Certification All parts undergo dimensional validation via CMM, and NDT methods including X-ray and pressure testing per customer standards.

Key Challenges

Preventing micro-segregation in thick-section valve components

Managing porosity and oxide inclusion risk during melt and pour

Ensuring long-term corrosion resistance after machining and welding

Achieving full traceability and compliance with oil & gas quality standards

Results and Verification

Grain size ASTM 5–6 confirmed via metallography

Tensile and yield strength exceeded NACE MR0175 requirements

Leak testing passed at 1.5× operating pressure

100% dimensional conformance confirmed via CMM

100% NDT pass rate across production batches

FAQs

What are the advantages of Inconel 625 in pump and valve applications?

How does equiaxed casting benefit corrosion-resistant parts?

Can Inconel 625 castings be welded or repaired?

What testing is performed to validate structural integrity?

Which industries use Inconel 625 cast pump and valve parts?