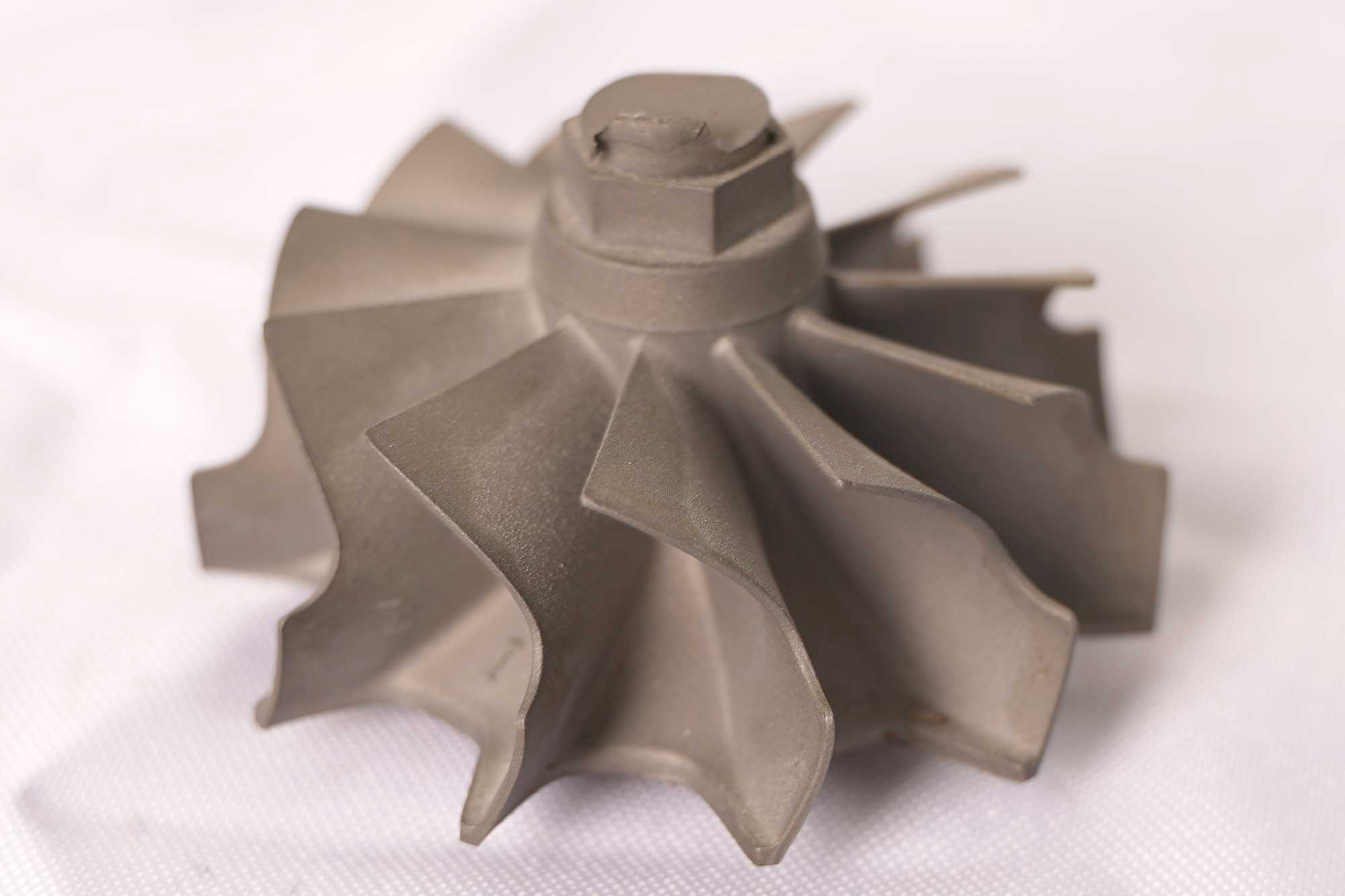

High-Temperature Alloy Precision Forging Turbine Rotors

Introduction

High-temperature alloy precision forging is essential for manufacturing turbine rotors that must endure extreme thermal, mechanical, and centrifugal loads. At Neway AeroTech, we produce forged turbine rotors from advanced superalloys such as Inconel 718, Rene 88, and FGH97, providing outstanding tensile strength (>1300 MPa), low-cycle fatigue resistance, and structural integrity in environments exceeding 700°C. These components are widely used in aerospace, power generation, and military and defense sectors.

By refining the grain flow and eliminating porosity, precision forging ensures long service life, enhanced rotor balancing, and optimized performance in high-speed turbine systems.

Core Technology of High-Temperature Alloy Precision Forging

Billet Preparation: Superalloy ingots are heated to 1050–1150°C, ensuring plasticity while maintaining grain integrity during deformation.

Closed-Die Forging: Controlled-force forging forms rotors under high pressure, aligning grain flow along radial and axial stress lines to improve strength.

Grain Structure Optimization: Fine and uniform grains (ASTM 10–12) are achieved, minimizing fatigue crack initiation and creep deformation under cyclic thermal loading.

Solution and Aging Heat Treatment: Post-forging heat treatment develops γ′ strengthening phases, improving tensile and fatigue properties.

Precision Machining: Multi-axis CNC machining ensures final tolerances within ±0.01 mm, critical for balancing and fit.

Surface Enhancement: Thermal Barrier Coating (TBC) optionally applied to improve oxidation and heat resistance in hot-section rotors.

Material Characteristics of Forged High-Temperature Alloy Rotors

Property | Specification |

|---|---|

Common Alloys | Inconel 718, Rene 88, FGH97, Udimet 720 |

Ultimate Tensile Strength | 1200–1450 MPa |

Yield Strength | ≥950 MPa |

Operating Temperature | Up to 750°C |

Fatigue Resistance | Low- and high-cycle fatigue rated |

Creep Resistance | Excellent at sustained high temperatures |

Dimensional Tolerance | ±0.01 mm (CNC-finished) |

Grain Size | ASTM 10–12 |

Case Study: Forged Superalloy Turbine Rotor for Industrial Gas Turbine

Project Background

A turbine OEM required forged rotors with high fatigue strength and zero-defect tolerance for a 50 MW-class industrial gas turbine. The component needed to operate above 700°C, withstanding 15,000+ rotational cycles under continuous stress.

Common Rotor Applications and Functions

Gas Generator Rotors: Central to turbine engines, transmitting torque from combustion to downstream stages under sustained high-speed rotation.

Power Turbine Rotors: Used in industrial and marine turbines, these components endure combined thermal gradients and torsional loads.

Aeroengine HP Rotors: Forged from Inconel 718 and FGH97, optimized for cyclic fatigue in aerospace engines operating at >15,000 RPM.

Steam Turbine Rotors: Forged from high-Cr nickel alloys, built for thermal stability and dimensional control in thermal power plants.

Rotor Manufacturing Solution

Billet Forging: Superalloy billets heated to 1120°C and forged using high-tonnage hydraulic presses for grain alignment and net shaping.

Flash Removal and Final Shape Forming: Forgings trimmed and resized to achieve concentricity and eliminate geometrical distortion.

Solution + Aging Treatment: Full cycle heat treatment at 1150°C (solution) and 760–800°C (aging) produces γ′ phase strengthening.

Finish Machining: 5-axis CNC machining delivers final blade root slots, bearing journals, and aerodynamic profiles within ±0.01 mm.

Surface Treatment (TBC): For hot-section rotors, TBC coatings provide oxidation and heat protection.

Inspection and Testing: Internal soundness validated using X-ray and ultrasonic NDT. Geometry confirmed via CMM inspection.

Balance and Validation: Dynamic balancing performed to ISO grade G1.0 to ensure vibration-free operation at high RPM.

Manufacturing Challenges and Solutions

Maintaining low residual stress during multi-stage forging

Achieving accurate grain flow in complex geometries

Ensuring dimensional repeatability for rotor-stator alignment

Verifying long-term creep and fatigue resistance at 750°C

Results and Validation

Mechanical Strength: UTS >1350 MPa, YS >1000 MPa consistently achieved after full processing.

Fatigue Performance: LCF and HCF tests showed life expectancy beyond 35,000 cycles under simulated service loads.

Dimensional Accuracy: Final tolerances measured via CMM were within ±0.01 mm on all critical rotor sections.

Surface Quality: Ra <1.6 µm confirmed after machining and optional coating for aerodynamic efficiency.

Internal Integrity: 100% passed NDT with no subsurface defects detected via radiographic and ultrasonic testing.

FAQs

What high-temperature alloys are suitable for precision-forged turbine rotors?

How does grain orientation affect rotor performance in turbine engines?

What’s the typical dimensional tolerance for finished forged rotors?

Can turbine rotors be coated with thermal barrier coatings?

What quality control methods are used to verify rotor integrity?