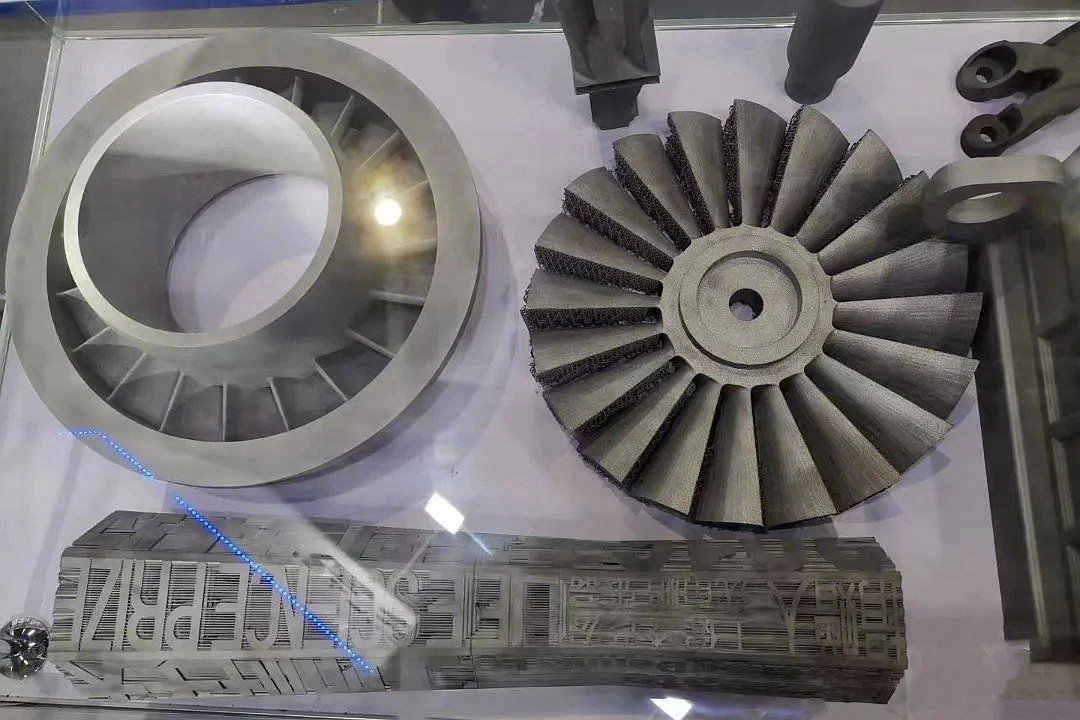

Hastelloy X Super Alloy 3D Printing Custom Turbine Wheel Components

Introduction to 3D Printing Hastelloy X Turbine Wheels

Hastelloy X is a nickel-chromium-iron-molybdenum superalloy designed for exceptional strength, oxidation resistance, and thermal stability at elevated temperatures. It is widely used in combustion-zone turbine parts, where heat resistance and fatigue performance are critical.

At Neway Aerotech, our Hastelloy X additive manufacturing services leverage Selective Laser Melting (SLM) to produce custom turbine wheel components with optimized airflow geometry, internal cooling channels, and net-shape efficiency.

Additive Manufacturing Process for Turbine Components

SLM Process Capabilities for Hastelloy X

Parameter | Value | Description |

|---|---|---|

Layer Thickness | 30–50 μm | Supports fine contours and blade edges |

Surface Roughness (as built) | Ra 8–15 μm | Post-processing improves flow and fatigue life |

Build Volume | Up to 250 × 250 × 300 mm | Suitable for single-stage turbine wheel designs |

Feature Accuracy | ±0.05 mm | Ensures profile tolerance and airfoil fidelity |

Post-Processing | HIP + Aging, CNC finishing | Required for fatigue and dimensional performance |

Why Hastelloy X Is Ideal for Turbine Wheels

Property | Value | Functional Benefit |

|---|---|---|

Operating Temperature | Up to 1175°C | Excellent for combustion-facing turbine sections |

Oxidation Resistance | Stable to 1150°C | Maintains surface integrity during thermal cycling |

Tensile Strength | >750 MPa at 1000°C | Retains strength under turbine loading conditions |

Thermal Fatigue Resistance | High | Withstands repeated ignition/shutdown cycles |

Weldability | Excellent in SLM | Allows repair and complex builds without cracking |

Material and Post-Treatment Strategy

Powder: Gas atomized Hastelloy X, D50 = 35 µm, spherical morphology.

Printing: SLM in argon chamber at 40 μm layer height for precision blade geometry.

Heat Treatment: HIP at 1160°C / 100 MPa for 4 hours; aging at 760°C to stabilize grain boundaries.

Machining: CNC finishing for bore concentricity, balancing surfaces, and hub interfaces.

Case Study: 3D Printed Hastelloy X Turbine Impeller for Power Generation

Project Background

A power turbine OEM required a custom turbine impeller for a high-efficiency microturbine project. The part required high-temperature creep resistance, tight blade tolerance, and integrated cooling holes that were not possible with traditional casting.

Manufacturing Workflow

Design: STL file included 17 airfoils with internal channels; max OD 120 mm; wall thickness 1.5 mm.

Printing: SLM at 40 μm layers using 350 W laser; inert chamber with O₂ < 100 ppm.

Post-Processing:

HIP and aging for strength.

Flow path polished to Ra ≤ 4 μm.

CMM inspection and X-ray ensured dimensional and internal quality.

Dynamic Balancing: Finished wheel balanced per ISO 1940 G2.5 standard.

Results and Verification

The 3D printed Hastelloy X turbine wheel passed 1000-hour thermal fatigue testing at 1100°C and 60,000 rpm. Airfoil deviation was under ±0.02 mm, and internal cooling channels showed uniform cross-sectional flow. The component exceeded performance benchmarks for use in a 250 kW microturbine.

FAQs

What is the thermal fatigue performance of SLM Hastelloy X turbine wheels?

How does 3D printing improve cooling channel integration in impellers?

What heat treatment is required after printing Hastelloy X components?

Can Hastelloy X be used for rotating and stationary turbine components?

What is the typical lead time for a custom 3D printed turbine wheel?