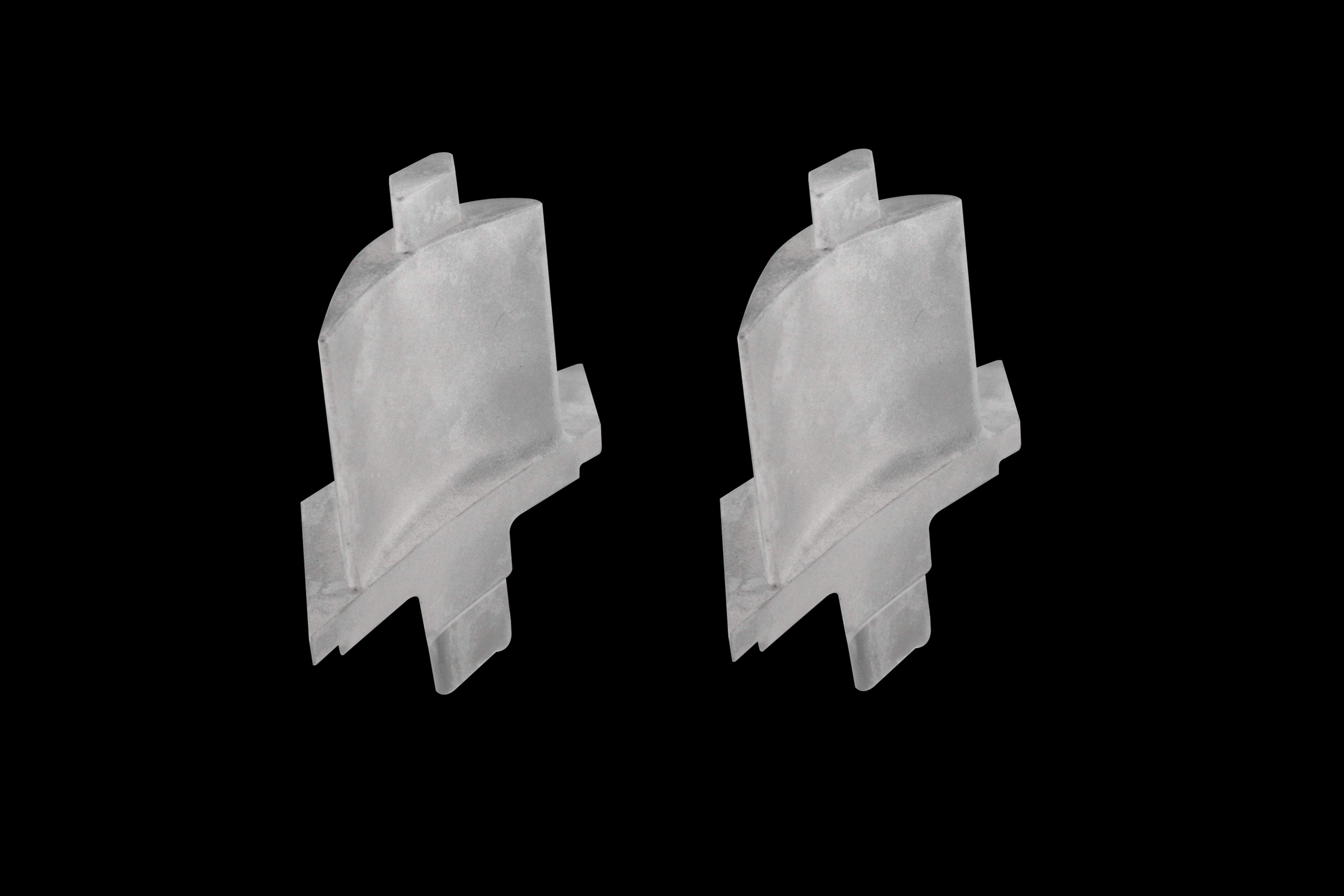

CMSX-8 Superalloy CNC Machining Steam Turbine Blades

Introduction

CMSX-8 superalloy CNC machining is a vital post-casting process that transforms single crystal blades into fully functional, dimensionally precise components used in advanced steam turbine systems. At Neway AeroTech, we apply precision machining to CMSX-8 blades for power generation and industrial steam turbines where high thermal loads, pressure gradients, and corrosion are major design challenges.

CMSX-8 offers superior creep strength, oxidation resistance, and phase stability at temperatures up to 1100°C, making it ideal for last-stage and reheat steam turbine blades subjected to thermal fatigue and high-cycle operation.

Core Technology of CMSX-8 CNC Machining

Pre-Machining Inspection: Cast blades undergo X-ray inspection and dimensional verification to confirm suitability for machining.

Fixturing and Orientation: Custom jigs ensure stable clamping and accurate orientation of airfoil and root for repeatable multi-axis operations.

5-Axis CNC Machining: Airfoil profiles, platform faces, and root geometries are machined to ±0.01 mm using carbide tooling with optimized coolant strategies.

Cooling Slot and Hole Finishing: Film cooling holes and radial slot features finished using EDM and high-precision drilling to avoid surface microcracking.

Stress Relief and Cleaning: Post-machining thermal cycle and ultrasonic cleaning ensure dimensional stability and surface readiness for coating.

Final Quality Assurance: Critical features verified using CMM, with contour accuracy and surface finish (Ra ≤ 0.8 µm) documented.

Material Characteristics of CMSX-8 in Machined Form

Property | Value |

|---|---|

Max Operating Temperature | 1100°C |

Ultimate Tensile Strength | ≥1250 MPa |

Creep Resistance | Excellent |

Grain Structure | Single crystal <001> |

γ′ Volume Fraction | ~70% |

Fatigue Resistance | Very High |

Surface Finish (Post-CNC) | Ra ≤ 0.8 µm |

Case Study: CNC Machined CMSX-8 Blades for High-Output Steam Turbine Upgrade

Project Background

A utility provider required upgraded blades for a reheat-stage steam turbine running above 1000°C. The client selected CMSX-8 for its long-term creep performance and oxidation stability. Machining accuracy was critical for aerodynamic performance and vibration minimization.

Typical Applications of CMSX-8 CNC Machined Steam Turbine Blades

Reheat Stage Blades in Power Turbines: CMSX-8 blades machined for high-load reheat sections where thermal cycling and creep damage are dominant.

Last-Stage Blades in Combined-Cycle Turbines: Precision-machined blades endure wet steam conditions, requiring corrosion resistance and exact fit to minimize flutter.

Industrial Steam Expander Blades: Used in process steam systems for power recovery, CMSX-8 offers fatigue life and stability under variable loading.

Steam Turbine Retrofit Components: CMSX-8 blades machined to replace older equiaxed or DS blades with improved durability and thermal stability.

Manufacturing Workflow

Casting Validation: CMSX-8 blades validated for grain orientation using EBSD and internal soundness via X-ray.

Workholding and Setup: 5-axis fixtures calibrated to hold each blade with consistent alignment throughout machining.

Machining Process: Multi-surface blade features cut with ±0.01 mm accuracy; tool paths optimized for superalloy hardness and blade curvature.

EDM and Hole Drilling: Cooling features produced using spark erosion and microdrilling to preserve structural integrity.

Stress Relief: Controlled thermal treatment to relieve machining stress before finishing and coating.

Final Inspection: All blade surfaces measured with CMM and profile laser scanning for airfoil fidelity.

Results and Validation

Dimensional Precision: Airfoil and root features achieved within ±0.01 mm; repeatability confirmed across full production run.

Surface Quality: Ra ≤ 0.8 µm on pressure and suction sides; burr-free edges and defined trailing edge maintained.

Creep and Fatigue Endurance: Machined CMSX-8 blades met creep life target of 1000 hours at 1050°C and >25,000 HCF cycles.

Cooling Hole Accuracy: Hole diameters within ±0.02 mm and spacing within ±0.05 mm; airflow verified via flow bench testing.

No Structural Defects: X-ray and EBSD confirmed no grain misalignment or internal casting defects post-machining.

FAQs

Why is CMSX-8 suitable for steam turbine blade applications?

What challenges exist when machining CMSX-8 blades?

How does CNC precision affect aerodynamic performance of turbine blades?

Can CMSX-8 blades be coated after CNC machining?

Does Neway AeroTech offer small-lot or prototype machining for steam turbine retrofits?