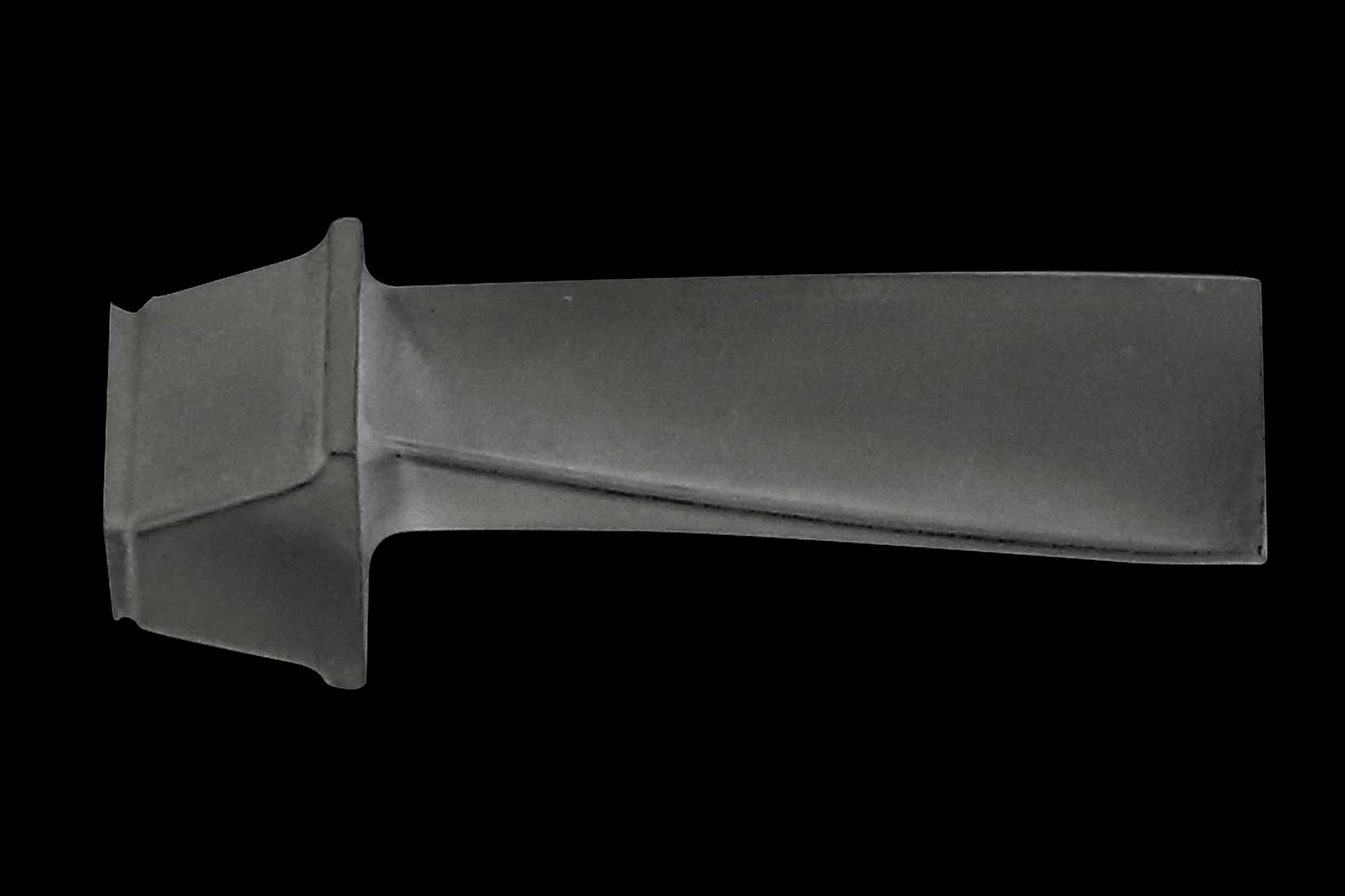

CMSX-486 Vacuum Investment Casting Rocket Engine Blades

Introduction

CMSX-486 vacuum investment casting is a specialized process used to manufacture high-performance turbine blades for rocket engine turbopumps and thrust-generation assemblies. At Neway AeroTech, we utilize advanced directional solidification technology to cast CMSX-486 single crystal blades with excellent creep resistance, thermal fatigue durability, and oxidation stability in environments exceeding 1150°C.

CMSX-486 is engineered for applications requiring high γ′ content, superior hot-corrosion resistance, and excellent phase stability, making it ideal for reusable rocket engine turbine stages, where material integrity under extreme stress is non-negotiable.

Core Technology of CMSX-486 Casting

High-Precision Wax Patterning: Wax blades produced with ±0.05 mm accuracy to replicate intricate root, platform, and cooling geometries.

Ceramic Shell Mold Construction: Shells built using 8–10 layers of high-purity ceramic, providing thermal and mechanical integrity during casting.

Vacuum Melting and Casting: CMSX-486 alloy melted and poured under vacuum (<10⁻³ torr) to maintain chemical purity and eliminate oxygen inclusion.

Directional Solidification: The Bridgman process enables controlled <001> single crystal growth with withdrawal rates of 3–6 mm/min.

Post-Casting Heat Treatment: Solution and aging at high precision to develop optimal γ/γ′ phase structure and eliminate residual segregation.

CNC Machining and Finishing: Airfoil, root interface, and platform faces are machined to ±0.02 mm using 5-axis CNC machining.

Optional Surface Coating: TBC coatings applied to minimize metal temperature and extend blade life in combustion environments.

Material Properties of CMSX-486

Property | Value |

|---|---|

Max Operating Temperature | 1170–1200°C |

Ultimate Tensile Strength | ≥1250 MPa |

Creep Rupture Life | >1000 hrs at 1100°C / 137 MPa |

γ′ Volume Fraction | ~70% |

Oxidation Resistance | Excellent |

Grain Structure | Single crystal <001> |

Phase Stability | Superior under cyclic thermal stress |

Case Study: CMSX-486 Rocket Turbopump Blade for Reusable Engine System

Project Background

A spaceflight propulsion company required rocket engine turbine blades for a staged combustion cycle engine capable of multiple reuses. The blades needed to maintain crystal integrity and fatigue resistance under extreme thermal loads and rapid cycle starts. CMSX-486 was selected due to its optimized creep and oxidation properties.

Applications of CMSX-486 in Rocket Engine Blades

Rocket Turbopump Turbine Blades: Operate under >1150°C hot gas flow, with >30,000 RPM rotational speeds and cyclic temperature variations.

Oxidizer Turbine Stages: CMSX-486 blades used in LOX turbomachinery for staged combustion systems requiring extreme mechanical strength and low deformation.

Thrust Chamber Drive Turbines: Blades maintain structural accuracy despite exposure to aggressive combustion gas chemistry and high backpressure environments.

Reusable Engine Hot Section Blades: Applied in commercial space launch systems designed for 10+ reuse cycles without performance degradation.

Manufacturing Workflow

Wax Assembly and Mold Orientation: Blade waxes are aligned and assembled into clusters for <001> orientation growth during casting.

Ceramic Mold Building and Drying: Shell thickness controlled to avoid thermal distortion and ensure clean separation after casting.

Vacuum Casting with Directional Solidification: CMSX-486 poured at ~1500°C, with directional withdrawal to create a single grain aligned to the primary stress axis.

Heat Treatment: Solution at 1280–1320°C and aging at 1080–870°C enhance γ′ formation and creep resistance.

Precision CNC Finishing: Root slots, seal faces, and cooling holes machined using high-speed CNC platforms to ensure accurate assembly.

Surface Coating (If Needed): Air plasma-sprayed TBCs applied to blades in extended high-cycle conditions.

Quality Inspection: X-ray NDT checks for casting voids; EBSD testing confirms crystal orientation; CMM used for final dimensional verification.

Results and Validation

Creep Resistance: Passed >1000-hour creep tests at 1100°C/137 MPa with elongation <1.2%.

Thermal Fatigue Performance: Endured 25,000+ cycles from ambient to 1170°C with no grain boundary initiation or cracking.

Dimensional Control: Final blade features confirmed within ±0.02 mm across bore, platform, and root sections.

Grain Orientation Compliance: EBSD confirmed <001> alignment within 10° for all production blades.

Oxidation Stability: TBC-coated blades maintained integrity after 1500-hour thermal exposure at 1200°C in simulated exhaust gas.

FAQs

What makes CMSX-486 suitable for reusable rocket engine turbine blades?

How does vacuum investment casting ensure crystal alignment in CMSX-486 components?

What’s the difference between CMSX-486 and CMSX-4 or CMSX-10 in thermal performance?

How does Neway AeroTech validate single crystal orientation in each blade?

Can CMSX-486 blades be customized for small-lot or prototype rocket engine programs?