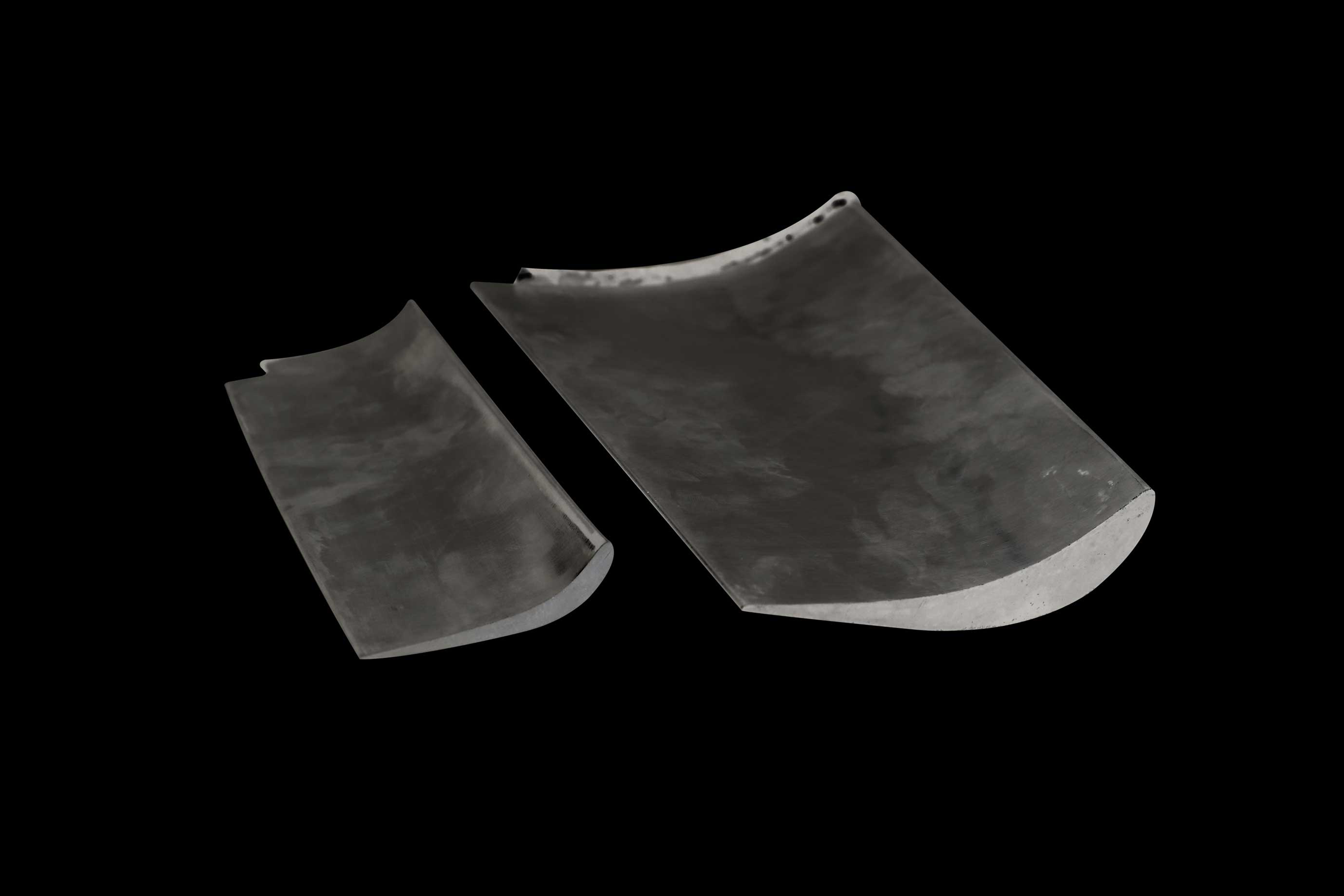

CMSX-2 Superalloy CNC Machining Compressor Blades

Introduction

CMSX-2 superalloy CNC machining is a critical post-processing step in the production of advanced compressor blades for high-performance turbine engines. At Neway AeroTech, we specialize in machining single-crystal CMSX-series superalloys with extreme dimensional accuracy (±0.01 mm), smooth aerodynamic surfaces, and excellent fatigue reliability for aerospace propulsion systems and military engines.

CMSX-2, with its high γ′ content and directional mechanical properties, provides excellent creep strength and oxidation resistance up to 1100°C, making it ideal for HPC (high-pressure compressor) and turbine transition blades where thermal stress and mechanical load are intense.

Core Technology of CMSX-2 CNC Machining

Pre-Machining Inspection: Cast blades undergo X-ray inspection and dimensional pre-checks to ensure suitability for CNC processing.

Fixture and Alignment Setup: Custom-designed fixtures and blade orientation systems ensure repeatable and secure clamping without stress distortion.

5-Axis CNC Machining: High-speed machining of airfoil surfaces, platform faces, root forms, and shroud edges to ±0.01 mm tolerance using carbide tools and advanced coolant strategies.

Surface Finish Control: Surface roughness reduced to Ra ≤0.8 µm on flow path areas for improved aerodynamic efficiency and fatigue performance.

Cooling Hole and Slot Machining: Micro EDM and high-precision drilling systems are used to open cooling holes, trailing edge slots, and seal slots on CMSX-2 parts.

Stress Relieving and Cleaning: Low-temperature heat treatment followed by ultrasonic cleaning ensures dimensional stability and readiness for coating.

Final Inspection: Coordinate Measuring Machine (CMM) and surface profilometry validate contour, edge definition, and positional tolerances.

Material Characteristics of CMSX-2 in Machined Blade Form

Property | Value |

|---|---|

Max Operating Temperature | ~1100°C |

Ultimate Tensile Strength | ≥1240 MPa |

Creep Resistance | Excellent at elevated temperature |

Microstructure | Single crystal, <001> oriented |

γ′ Volume Fraction | ~65% |

Machinability | Low (requires carbide or ceramic tooling) |

Surface Finish (Post-CNC) | Ra ≤0.8 µm |

Case Study: CNC Machined CMSX-2 Blades for High-Pressure Compressor Module

Project Background

A military aircraft engine program required precision-machined CMSX-2 compressor blades for the third stage of a high-pressure compressor (HPC) module. The customer specified tight dimensional tolerances (±0.01 mm), high fatigue life, and consistent blade profile for performance matching.

Typical Applications of CMSX-2 CNC Machined Compressor Blades

GE F110 Engine HPC Blades: CMSX-2 blades used in early turbine stages, combining high creep strength and tight profile control.

Eurojet EJ200 Compressor Blades: Machined CMSX-2 airfoils ensure aerodynamic balance and longevity in supersonic fighter platforms.

Industrial Aero-Derivative Compressor Modules: Used in energy sector turbines for gas compression and offshore power turbines requiring single crystal creep strength with tight dimensional control.

Manufacturing Solution

Blade Casting Validation: Each blade is inspected for dimensional consistency and grain orientation using EBSD.

Custom Fixturing: 5-axis workholding fixtures designed to accommodate complex airfoil geometry without distortion.

Precision Machining: All profile sections, root fillets, and seal notches are machined in a single setup to ensure tolerance stack-up control.

Toolpath Optimization: CAM software used to generate cutter paths that minimize tool deflection and heat generation on the superalloy surface.

Cooling Feature Finishing: EDM and high-accuracy gun drilling used to finish film cooling holes and radial cooling slots without microcracking.

Stress Relief and Cleaning: Controlled post-machining heat cycle applied to reduce residual stress and surface tension effects.

Final Metrology: 3D laser scanning and CMM used to verify airfoil contour, platform thickness, and all critical dimensions.

Results and Validation

Dimensional Accuracy: All blade profiles met ±0.01 mm tolerances; bore and platform faces aligned within ±0.005 mm.

Surface Finish Quality: Ra ≤0.8 µm achieved on all leading edges and pressure sides, exceeding aerodynamic performance targets.

Fatigue Life Assurance: Machined blades demonstrated fatigue strength retention over 20,000 high-cycle fatigue cycles at 900°C in simulation.

Cooling Hole Accuracy: Cooling hole positions within ±0.05 mm and diameter within ±0.02 mm; flow area verified through airflow testing.

Defect-Free Machining: Post-machining inspections confirmed no microcracks, burrs, or stress-related warping.

FAQs

Why is CMSX-2 used for compressor blades and not just turbine blades?

What makes CNC machining of CMSX-2 challenging compared to other superalloys?

How does surface finish affect compressor blade aerodynamic performance?

What quality control methods are used to verify machined blade geometry?

Can CMSX-2 blades be repaired or re-machined if damaged during service?