CMSX-11 Single Crystal Casting Turbine Blades and Vanes

Introduction

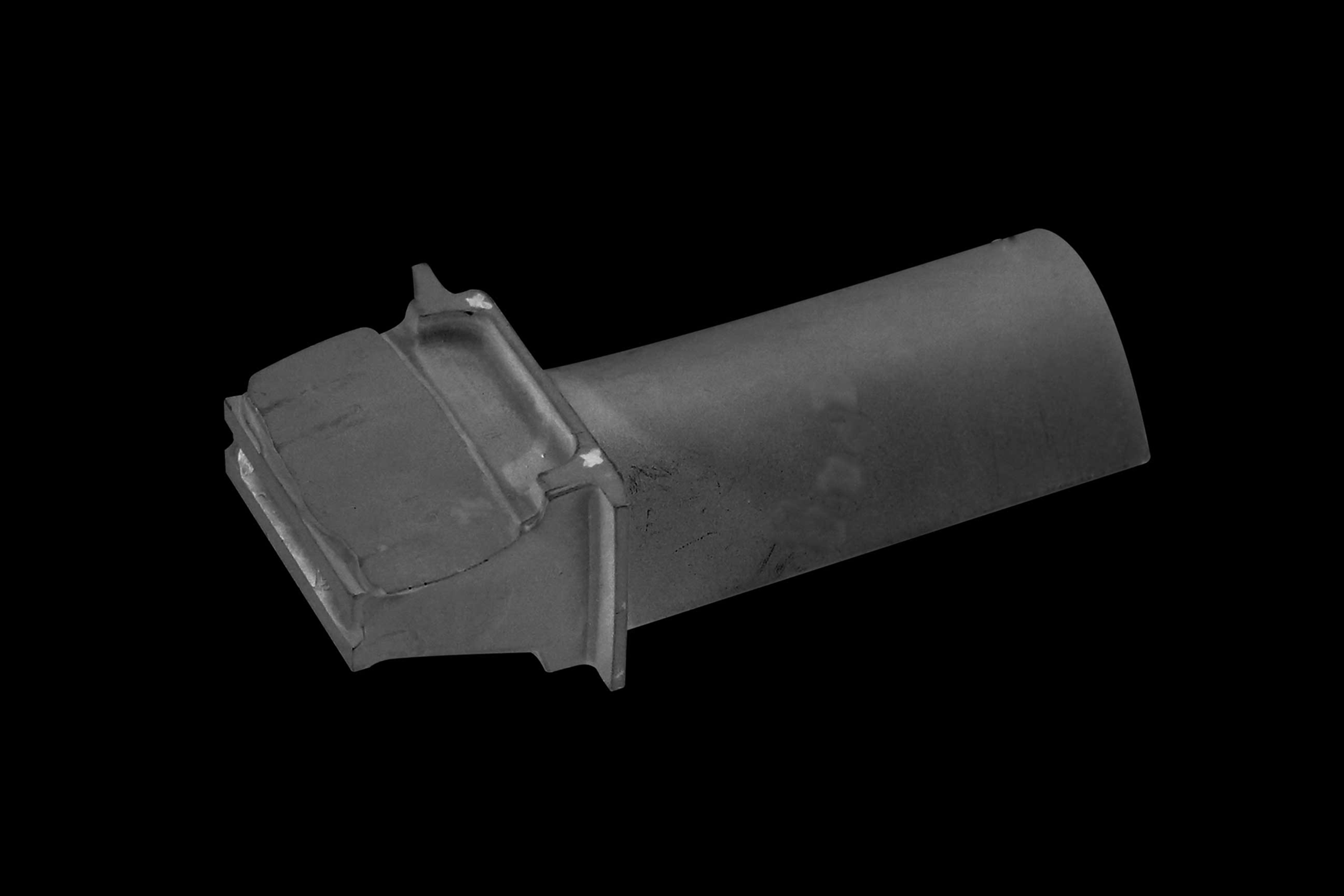

CMSX-11 single crystal casting enables the production of next-generation turbine blades and vanes that operate reliably under extreme heat, high mechanical stress, and corrosive gas environments. At Neway AeroTech, we manufacture CMSX-11 blades and vanes using advanced vacuum directional solidification techniques, tailored for aerospace engines, power generation turbines, and military propulsion systems.

CMSX-11 offers improved creep rupture life, higher γ′ content (~72%), and enhanced oxidation resistance compared to earlier CMSX alloys, making it ideal for first-stage turbine components operating above 1150°C.

Core Technology of CMSX-11 Casting

Wax Pattern Generation: Precise airfoil, platform, and root geometries are molded using high-fidelity wax tooling with ±0.05 mm repeatability.

Ceramic Shell Mold Building: 8–10 ceramic layers are applied to create a high-strength mold suitable for vacuum investment casting.

Vacuum Melting and Pouring: CMSX-11 superalloy is melted and cast under vacuum (<10⁻³ torr) to ensure chemical stability and eliminate oxidation.

Directional Solidification (DS): Blades and vanes are cast using the Bridgman method at 3–6 mm/min withdrawal, ensuring single crystal growth along the <001> direction.

Post-Casting Heat Treatment: Solution and aging treatment optimizes γ′ distribution and dissolves segregations to achieve full mechanical properties.

CNC Machining and Finishing: Root attachments, cooling holes, and platform surfaces are machined using multi-axis CNC machining with tolerances within ±0.02 mm.

Thermal Barrier Coating (Optional): TBC coatings improve surface durability, corrosion resistance, and blade life in hot gas streams.

Material Properties of CMSX-11

Property | Value |

|---|---|

Max Operating Temperature | 1180–1200°C |

γ′ Volume Fraction | ~72% |

Creep Rupture Strength | >1000 hrs at 1100°C / 137 MPa |

Oxidation Resistance | Excellent |

Grain Structure | Single crystal <001> |

Fatigue Resistance | Very high (thermal and mechanical fatigue) |

Typical Applications | HPT blades and vanes, power turbine nozzles |

Case Study: CMSX-11 Blade and Vane Set for First-Stage Military Turbine

Project Background

A military aircraft engine manufacturer required a high-performance blade and vane system for the first stage of a high-thrust turbofan. CMSX-11 was selected for its improved γ′ stability and resistance to high-cycle thermal fatigue, delivering performance above 1150°C with extended mission profiles.

Applications of CMSX-11 Turbine Blades and Vanes

F414 HPT Blades (CMSX-11): Single crystal blades capable of continuous operation above 1170°C with high fatigue resistance in combat engines.

LM2500+ Turbine Vanes (CMSX-11): Used in marine and industrial power turbines requiring long-term oxidation and creep resistance.

Next-Gen Fighter Turbine Vanes: CMSX-11 vanes designed for stealth propulsion units under transient afterburner conditions.

APU Blades in Military Transports: Compact, high-cycle airfoils used in auxiliary turbines operating with frequent starts and stops.

Manufacturing Process

Wax Assembly and Orientation Control: Wax cluster design ensures consistent <001> alignment and uniform casting performance.

Shell Construction: Ceramic molds are dried under controlled temperature and humidity to prevent cracking and distortion.

Vacuum Casting with DS Furnace: Withdrawal rates and temperature gradients are optimized to achieve complete single crystal structure.

Post-Casting Heat Treatment: Two-step aging following high-temperature solutioning maximizes creep and oxidation performance.

CNC Machining: Blade roots, tenons, platform flanges, and vane shrouds are machined with ±0.02 mm tolerance using high-speed CNC tools.

Surface Treatment and Coating: TBC applied to high-heat-exposed zones for longer service life; polishing ensures aerodynamic smoothness.

Inspection and Validation: X-ray NDT checks for casting defects; EBSD confirms crystal orientation; CMM ensures geometric accuracy.

Results and Validation

Creep Performance: Passed 1000-hour creep rupture test at 1100°C under 137 MPa with minimal deformation.

Fatigue Endurance:

25,000 thermal cycles from 300°C to 1150°C passed with no crack initiation.

Grain Orientation Compliance: EBSD showed <001> alignment within 10° tolerance for 100% of blades and vanes.

Oxidation Resistance: TBC-coated blades maintained integrity after 1500-hour oxidation test at 1180°C.

Dimensional Accuracy: CNC and CMM validation confirmed ±0.02 mm tolerances on all machined features.

FAQs

What performance advantages does CMSX-11 offer over CMSX-4 or CMSX-10?

Can CMSX-11 be used for both blades and vanes in the same turbine stage?

What is the typical lifespan of CMSX-11 single crystal airfoils in aerospace applications?

How does Neway AeroTech control grain orientation and eliminate stray grains in CMSX-11 casting?

Can CMSX-11 blades be TBC-coated and still maintain cooling effectiveness and fatigue life?