How do Stellite alloys improve the performance of firearm components?

Exceptional Wear Resistance and Hardness

Stellite alloys, which are cobalt-based, are renowned for their exceptional resistance to abrasion, galling, and erosion. In firearm components such as extractors, ejectors, and sear surfaces, these parts are subject to repeated sliding contact and impact. The high carbon content in alloys like Stellite 6 forms hard carbides within a tough cobalt-chromium matrix, resulting in a surface that resists deformation and material loss significantly better than conventional tool steels. This directly translates to longer service life, maintained headspace, and consistent timing in automatic weapons, reducing the frequency of part replacement and maintenance downtime.

Retained Strength at High Temperatures

During sustained or rapid fire, critical components like barrel extensions, gas piston rings, and compensators can experience significant heat buildup. Unlike many steels that rapidly soften at elevated temperatures, Stellite alloys retain a large percentage of their hardness and strength even at red-hot conditions. This property, known as red-hardness, prevents peening, dimensional distortion, and catastrophic failure under thermal stress. This makes Stellite an ideal choice for military and defense applications where weapon reliability under extreme conditions is paramount.

Superior Corrosion and Oxidation Resistance

The high chromium content in Stellite alloys provides outstanding resistance to corrosion and oxidation. Firearms used in marine environments or with corrosive ammunition primers are highly susceptible to pitting and rust. Components made from Stellite are inherently more resilient to these attack vectors, ensuring functional reliability and preventing degradation that could lead to jams or mechanical failure. This corrosion resistance complements its wear properties, offering a comprehensive solution for durability in harsh operating conditions.

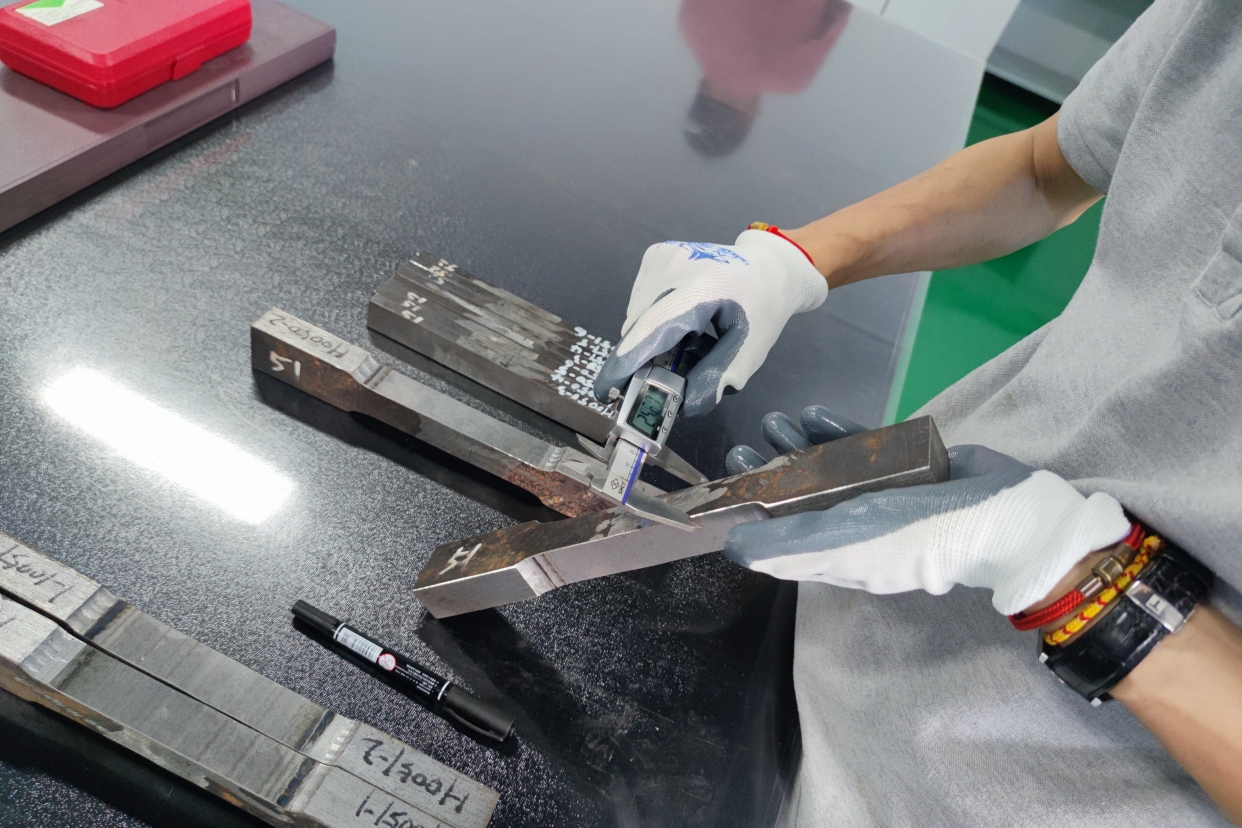

Manufacturing and Application Techniques

For complex, net-shape components, vacuum investment casting is an excellent manufacturing route for Stellite alloys. This process ensures excellent surface finish and dimensional accuracy for intricate part geometries. To further enhance the integrity of cast parts, Hot Isostatic Pressing (HIP) can be employed to eliminate internal microporosity, thereby increasing fatigue life and ductility. For repair or surface enhancement, Stellite is often applied as a wear-resistant coating via welding techniques, a service that falls under the expertise of superalloy welding.