How do Stellite alloys enhance the performance of armor system components?

Exceptional Wear and Abrasion Resistance

Armor system components face continuous mechanical stress, friction, and debris exposure. Stellite alloys, such as Stellite 6K and Stellite 21, provide excellent anti-galling properties and high hardness, making them ideal for sliding interfaces, high-load connectors, and structural joints. Their resistance to abrasive wear significantly extends service life in harsh defense environments.

Impact Toughness and Dimensional Stability

Armor components must withstand sudden impact and high dynamic loading. Stellite alloys retain strength under shock conditions and maintain dimensional accuracy with minimal plastic deformation. Alloys such as Stellite 12 offer a good balance between impact toughness and hardness, ideal for reinforcement structures and protective modules in military and defense systems.

Thermal and Corrosion Resistance

Armor systems often operate near exhaust sources or in chemically aggressive environments. Stellite alloys demonstrate strong resistance to oxidation and corrosion at elevated temperatures. Their stability makes them suitable for components exposed to heat, moisture, or salt fog, enhancing reliability across field operations.

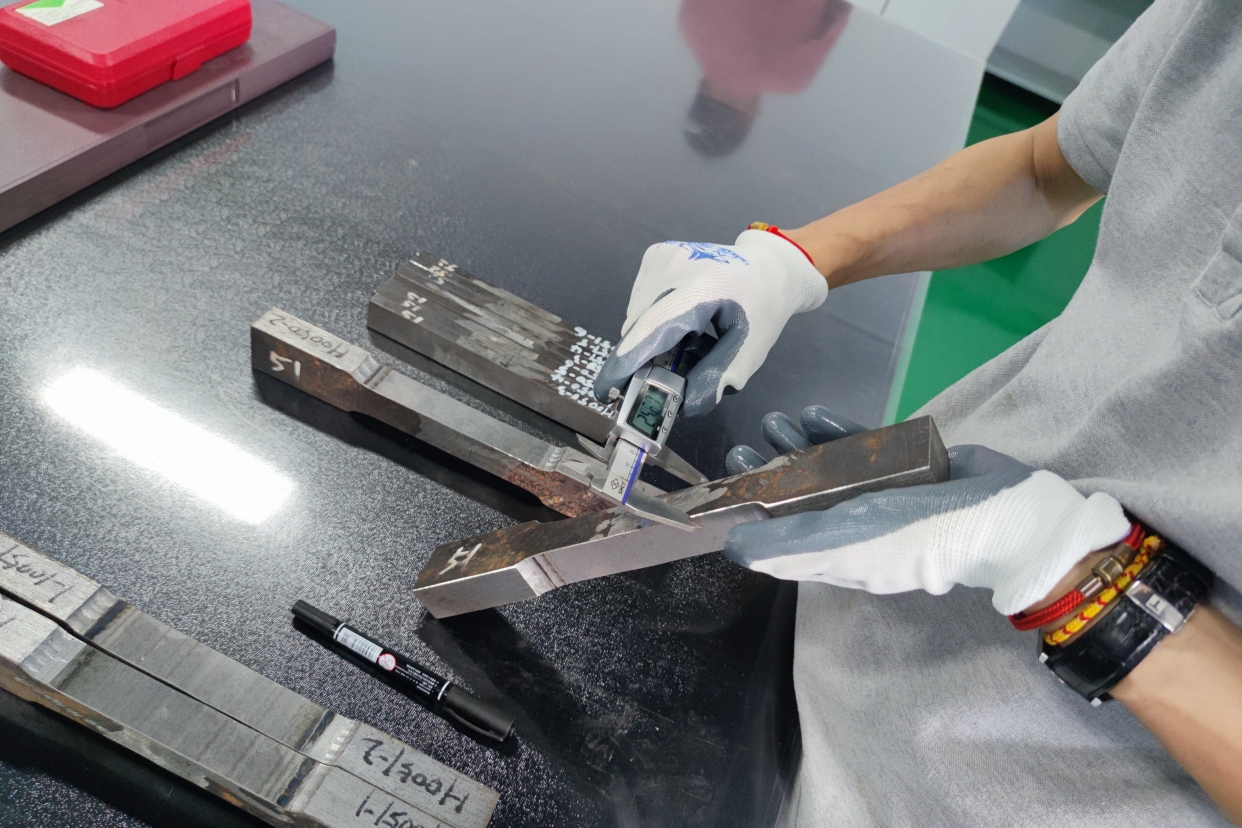

Compatibility with Advanced Manufacturing

Stellite alloys are compatible with precise production methods such as vacuum investment casting and finishing through superalloy cnc machining. Post-processing steps—including hot isostatic pressing (HIP)—further refine grain structure for higher fatigue resistance and structural uniformity, helping ensure performance consistency across armor assemblies.