18Ni300 (1.2709)

Material Introduction

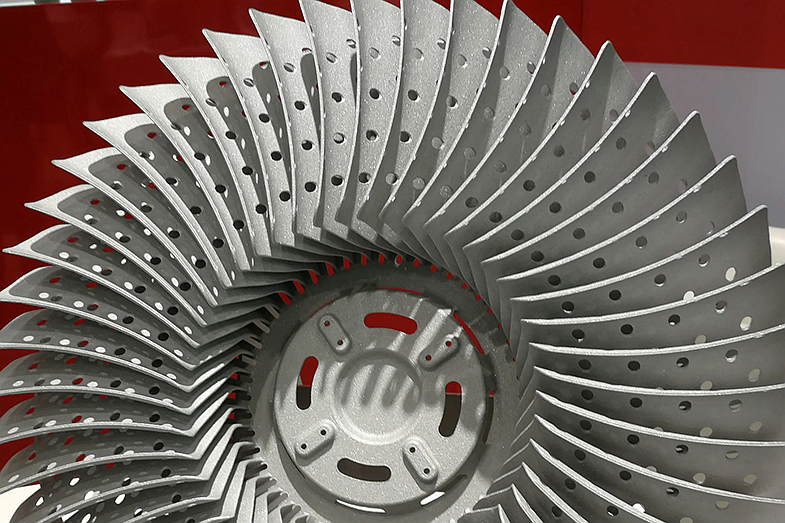

18Ni300, also known as 1.2709 maraging steel, is one of the most widely used ultra-high-strength tool steels for metal additive manufacturing. As a martensitic, precipitation-hardening alloy, it delivers exceptional toughness, outstanding dimensional stability, and very high tensile strength after aging. Through Neway AeroTech’s advanced stainless steel 3D printing technology, 18Ni300 enables rapid manufacturing of production-ready molds, tooling components, mechanical parts, and high-load structural elements. Its near-zero carbon content ensures excellent weldability and crack resistance, making it ideal for complex geometries and conformal cooling structures that traditional machining cannot achieve. The material’s predictable aging response enables engineers to achieve hardness levels comparable to those of premium tool steels, making 18Ni300 a high-performance, highly versatile solution for industrial-grade 3D-printed tooling and engineering applications.

International Names or Representative Grades

Region | Common Name | Representative Grades |

|---|---|---|

USA | Maraging Steel 300 | 18Ni300 |

Europe | 1.2709 Tool Steel | X3NiCoMoTi 18-9-5 |

Japan | High-Strength Maraging Steel | 18Ni300 |

China | Ultra-High-Strength Maraging Steel | 18Ni300 |

Mold Industry | Maraging Tool Steel | 300 Grade |

Alternative Material Options

Depending on application demands, several alternative metallic materials offer complementary performance advantages. For corrosion-sensitive environments, precipitation-hardening stainless steel such as Corrax provides excellent hardness with superior corrosion resistance. For general high-strength geometries, 17-4 PH delivers a balance of toughness and corrosion stability. If higher temperature capability is required, nickel-based alloys like Inconel 718 or Inconel 625 deliver superior creep and oxidation resistance. For applications requiring extreme wear performance, cobalt-based alloys such as Stellite 6 ensure longevity in abrasive environments. Where weight reduction is essential, high-performance titanium alloys like Ti-6Al-4V offer superior strength-to-density ratios.

Design Purpose

18Ni300 was originally developed to provide a tool steel with exceptional strength, extremely low distortion, and high toughness after aging treatment. Its very low carbon content prevents brittleness, allowing components to be welded and heat-treated with excellent stability. In 3D printing, 18Ni300 is specifically valued for producing conformal cooling molds, high-load industrial tooling, and complex mechanical parts that require predictable dimensional accuracy. Its design intent aligns perfectly with additive manufacturing’s ability to produce optimized, lightweight, and precision-engineered components without compromising material integrity.

Chemical Composition (Typical)

Element | Composition (%) |

|---|---|

Iron (Fe) | Balance |

Nickel (Ni) | 17–19 |

Cobalt (Co) | 8–12 |

Molybdenum (Mo) | 4.5–5.2 |

Titanium (Ti) | 0.6–1.2 |

Aluminum (Al) | ≤ 0.1 |

Carbon (C) | ≤ 0.03 |

Silicon (Si) | ≤ 0.1 |

Manganese (Mn) | ≤ 0.1 |

Physical Properties

Property | Value |

|---|---|

Density | ~8.0 g/cm³ |

Thermal Conductivity | 14–16 W/m·K |

Electrical Resistivity | ~0.75 μΩ·m |

Specific Heat | ~460 J/kg·K |

Aging Temperature | 480–520°C |

Mechanical Properties

Property | Typical Value |

|---|---|

Tensile Strength | 1900–2100 MPa (aged) |

Yield Strength | 1800–1950 MPa |

Hardness | 50–54 HRC (after aging) |

Elongation | 3–6% |

Impact Toughness | High for ultra-strong steels |

Key Material Characteristics

Extremely high mechanical strength after aging treatment

Excellent toughness and ductility for ultra-high-strength steel

Very low carbon content ensures high weldability and crack resistance

Outstanding dimensional stability after heat treatment

Predictable aging response for precise hardness control

Ideal for high-strength mold inserts and tooling components

Excellent printability with minimal risk of porosity when processed correctly

Compatible with complex internal cooling channels for injection molds

Superior fatigue resistance for cyclic mechanical loading

Highly reliable performance in long-term industrial operations

Manufacturability in Different Processes

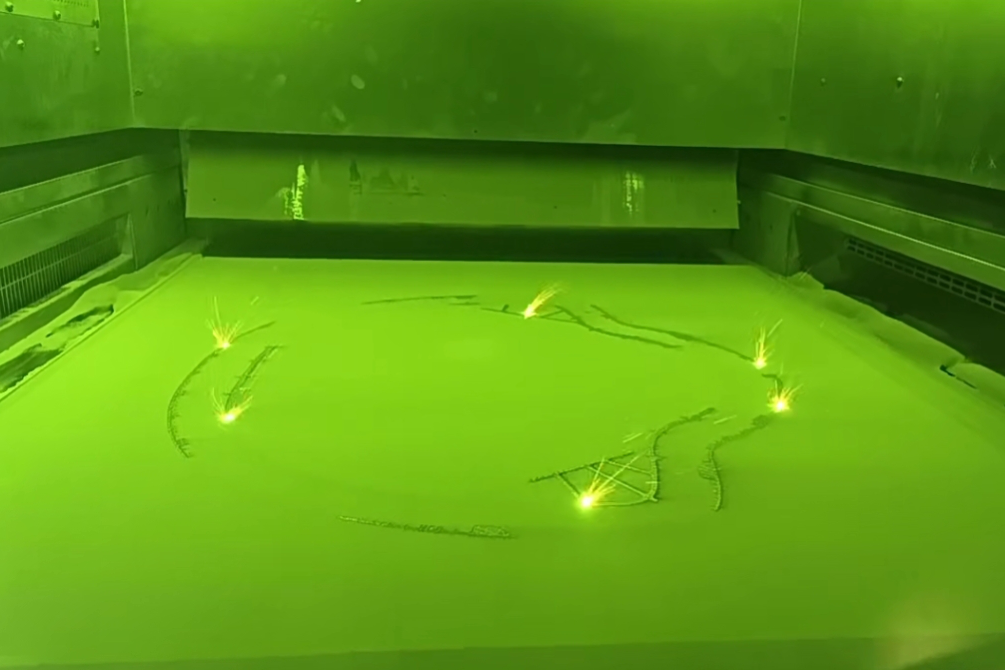

Additive manufacturing: Powder bed fusion enables the production of high-density, production-grade tooling and mechanical components using stainless steel 3D printing.

CNC machining: Machines effectively in the solution-treated state and complements precision finishing using superalloy CNC machining.

EDM: Suitable for detailed finishing and precise contouring through superalloy EDM.

Deep hole drilling: Compatible with advanced deep hole drilling methods for complex cooling channels.

Heat treatment: Responds reliably to solution treatment and aging through superalloy heat treatment.

Welding: Can be welded with proper control and further strengthened through aging using superalloy welding.

Casting: Although not a casting alloy, maraging steel metallurgy aligns with the logic of high-strength steel processing.

Suitable Post-Processing Methods

Aging treatment to achieve ultra-high strength and target hardness

Hot Isostatic Pressing (HIP) via HIP processing to eliminate internal porosity

Precision machining and grinding for mold-quality surface finishes

Polishing for optical-grade or injection mold applications

Surface strengthening treatments to enhance wear resistance

Nondestructive inspection using advanced material testing

Cleaning and fine processing for conformal cooling channels

Common Industries and Applications

Injection mold inserts and conformal cooling tooling

High-strength mechanical components and structural parts

Aerospace jigs, fixtures, and tooling elements

Automotive prototype molds and lightweight structural components

Industrial machinery components requiring extremely high strength

Defense and engineering parts are subjected to heavy cyclic loading

When to Choose This Material

When ultra-high strength and toughness are required simultaneously

When tooling must withstand high load and frequent mechanical cycling

When dimensional accuracy and low-distortion heat treatment are essential

When producing conformal cooling molds via additive manufacturing

When weldability and post-aging strength enhancement are necessary

When long-term durability outweighs initial material cost

When designing high-strength lightweight components without performance trade-offs

When rapid prototyping of functional tooling must match production-grade performance