GE: Single Crystal Casting and Post-Processing of First-Stage Turbine Blades

Introduction

In today’s aviation industry, achieving efficiency and durability in jet engines is paramount. The first-stage turbine blade, positioned closest to the combustion chamber, must withstand gas temperatures exceeding 1600°C and extreme mechanical stresses. General Electric (GE), a global leader in aerospace propulsion, has embraced advanced single crystal (SX) casting and post-processing techniques to meet these demanding requirements. This case study explores the end-to-end process of manufacturing these high-performance components.

GE Project Background and Design Requirements

GE’s latest generation of jet engines, such as the GE9X and LEAP series, push the boundaries of efficiency with higher turbine inlet temperatures and pressure ratios. The first-stage turbine blades in these engines demand:

Exceptional creep resistance at 1100–1150°C

Oxidation and corrosion resistance in aggressive environments

Fatigue strength under cyclic thermal loading

GE selected premium SX alloys such as CMSX-4 and Rene N5 due to their optimized γ/γ' microstructure and superior high-temperature stability. The intricate aerodynamic geometry of these blades also necessitated precision manufacturing. The project called for an integrated approach combining Single Crystal Casting expertise with advanced post-processing technologies.

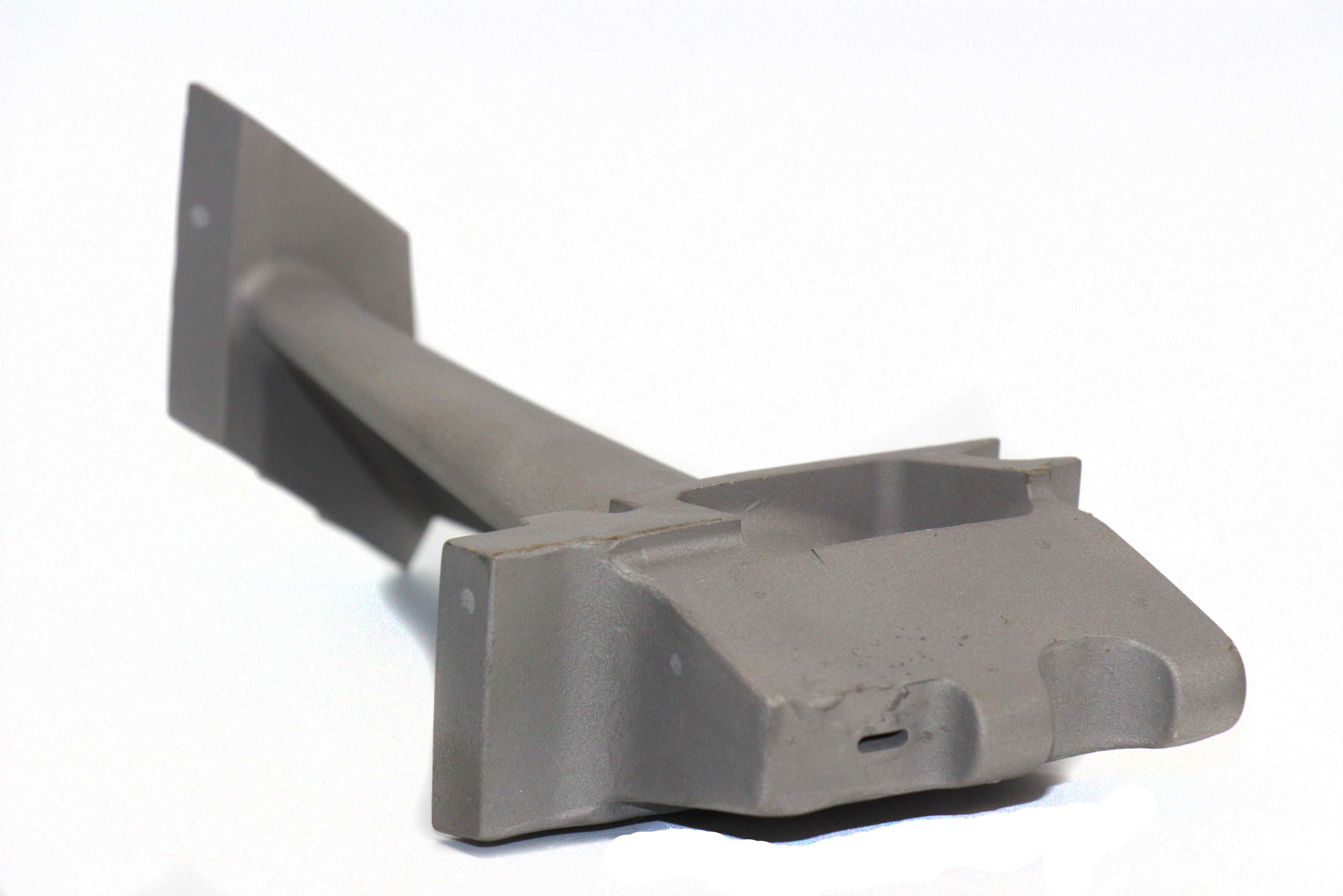

Single Crystal Casting Process Design

Process Planning

The foundation of SX turbine blade manufacturing is directional solidification using the Bridgman technique. GE engineers developed optimized process parameters:

Withdrawal rate: 2–4 mm/min

Thermal gradient: >20 °C/mm

Mold preheat: 1450–1500°C

A carefully calibrated thermal profile ensures that the blade solidifies as a single grain along the <001> crystallographic orientation, eliminating grain boundaries that would otherwise reduce creep strength.

Melting and Pouring

GE utilized Vacuum Investment Casting furnaces with high-purity inert atmospheres to prevent oxygen contamination. The process includes:

Vacuum melting of alloy ingots to 1600–1700°C

Ceramic mold preparation using Y2O3-based refractories

Controlled mold filling to prevent turbulence and oxide defects

Stringent process control minimizes common casting defects such as stray grain formation, microporosity, and segregation.

Defect Control and Quality Inspection

Defect Types

In SX blade manufacturing, defect prevention is critical. The following types are carefully controlled:

Low-angle boundaries (LAB)

Porosity and shrinkage cavities

Primary dendrite misorientation

Surface roughness and ceramic inclusions

Inspection Techniques

GE implemented multi-stage inspection protocols leveraging advanced NDT and metallographic analysis:

Inspection Method | Purpose | Example Equipment |

|---|---|---|

Detect internal porosity | Industrial CT | |

Crystal orientation mapping | SEM + EBSD | |

Trace element analysis | GDMS spectrometer | |

Microstructure verification | Metallographic microscope |

These techniques ensure that each blade meets stringent aerospace quality standards.

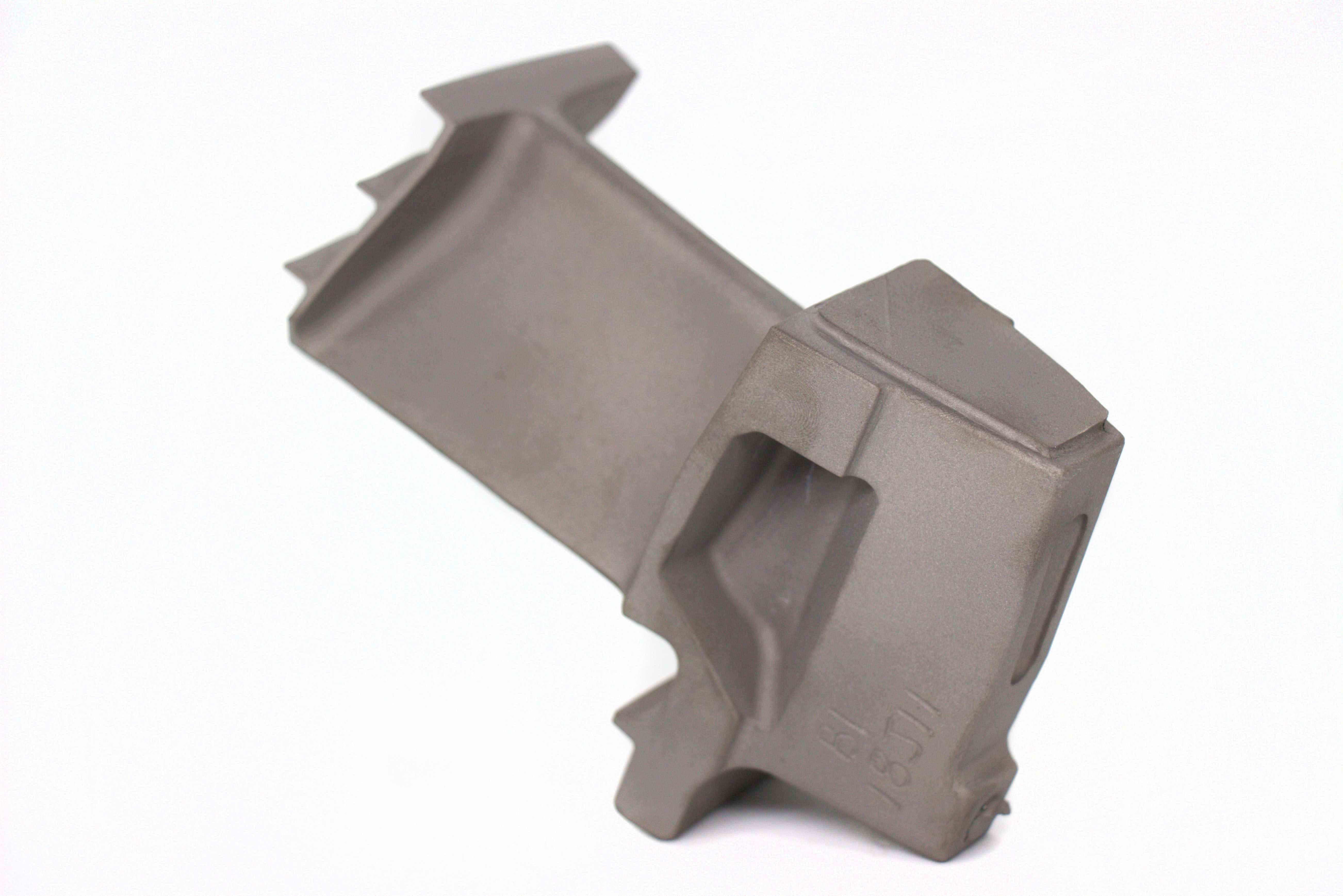

Post-Processing: HIP and Heat Treatment

Hot Isostatic Pressing (HIP)

Following casting, GE subjected blades to Hot Isostatic Pressing (HIP) at:

Temperature: 1200–1250°C

Pressure: 100–150 MPa

Time: 2–4 hours

HIP eliminates micro-porosity and homogenizes the microstructure, significantly enhancing fatigue life.

Heat Treatment

Post-HIP, blades underwent multi-step Heat Treatment:

Solution treatment: 1260–1280°C for γ' dissolution

Controlled cooling to optimize γ/γ' morphology

Aging treatment at 850–900°C to precipitate stable γ' phase

These treatments optimize mechanical properties such as creep strength and thermal fatigue resistance.

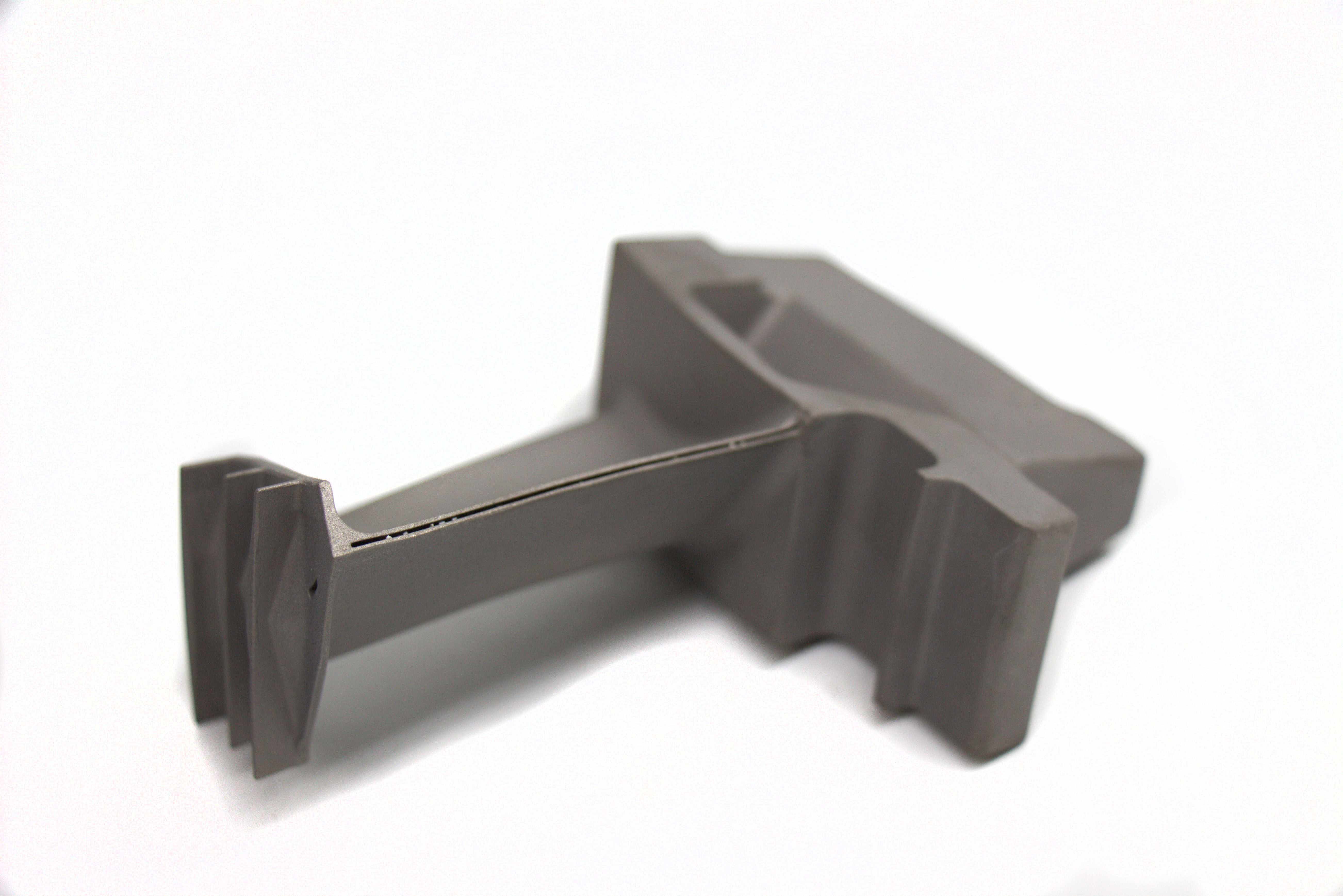

Surface Treatment: TBC and Surface Conditioning

To further enhance the durability of the first-stage turbine blades, GE applied advanced Thermal Barrier Coating (TBC). These coatings are critical for withstanding hot gas streams that can exceed the substrate alloy’s temperature limits.

The TBC system typically includes:

Bond coat: MCrAlY layer applied via HVOF or EB-PVD

Ceramic top coat: 6–8 wt.% Yttria-stabilized Zirconia (YSZ), ~150–250 µm thick

TBC coatings provide thermal insulation, reducing metal temperature by 100–150°C and extending component life.

In addition to TBC, precision surface treatments are conducted:

Polishing to achieve Ra < 1.5 µm

Shot peening for residual compressive stress

Controlled oxide scale formation for enhanced oxidation resistance

These finishing operations significantly improve resistance to high-cycle fatigue and corrosion.

Final Inspection and Qualification

Before shipment, each blade underwent comprehensive validation against aerospace standards:

Mechanical Testing

Tensile Testing: Room temperature and elevated temperature

Creep testing: Typically at 1050–1100°C under service-like stress conditions

Low-cycle and high-cycle fatigue testing

Non-Destructive Evaluation (NDE)

X-ray Inspection: 100% volumetric examination

Industrial CT scanning for complex features (e.g., internal cooling channels)

Surface integrity verification using eddy current and visual inspection

Certification

All blades were qualified to FAA and EASA aerospace requirements, meeting:

AMS 5385/AMS 5387 standards

ASTM E139, E606 for creep and fatigue

MIL-STD-2154 for radiographic acceptance

GE Application Results

The SX blades manufactured using this process have been deployed in:

GE LEAP-1A and 1B engines for Airbus A320neo and Boeing 737 MAX

GE9X engines for Boeing 777X

Field data over multiple years indicates:

20–25% creep life improvement over previous DS (directionally solidified) blades

10–15% thermal efficiency improvement due to tighter tip clearances

Significant reduction in fuel consumption and emissions

These performance gains support GE’s commitment to developing more sustainable and efficient aviation technologies.

Industry Trends and Future Outlook

The turbine blade manufacturing sector is evolving rapidly, driven by demands for:

Higher turbine inlet temperatures (TIT > 1700°C)

Extended component life cycles (targeting >30,000 flight hours)

Digital twin-based predictive maintenance

Emerging trends include:

Hybrid Manufacturing

Integrating Superalloy 3D Printing with traditional casting enables complex internal cooling structures and rapid prototyping.

Smart Coatings

Development of self-healing TBCs and real-time condition monitoring via embedded sensors.

AI-Driven Quality Control

Adoption of machine learning models to optimize casting parameters and predict defect formation.

As an engineer, it is exciting to witness how 3D printing service and advanced materials are reshaping turbine blade design possibilities.

Summary and Engineer’s Reflection

The manufacturing of GE's first-stage SX turbine blades exemplifies the pinnacle of materials engineering, precision casting, and post-processing. Success in this project hinged on:

Meticulous process design and control

Integration of advanced NDE and metallurgical analysis

Collaborative innovation across material science, mechanical engineering, and manufacturing disciplines

Looking ahead, the fusion of additive and subtractive manufacturing, coupled with smart coatings, holds immense potential for further performance breakthroughs.

As engineers, our mission remains clear: relentlessly push material and process limits to power the next generation of high-efficiency, low-emission jet engines.

FAQs

What are the key advantages of single crystal turbine blades in GE engines?

How does vacuum investment casting improve turbine blade quality?

What post-processing techniques are used on GE first-stage turbine blades?

What common defects are controlled during single crystal blade manufacturing?

How do TBC coatings enhance the performance of GE turbine blades?