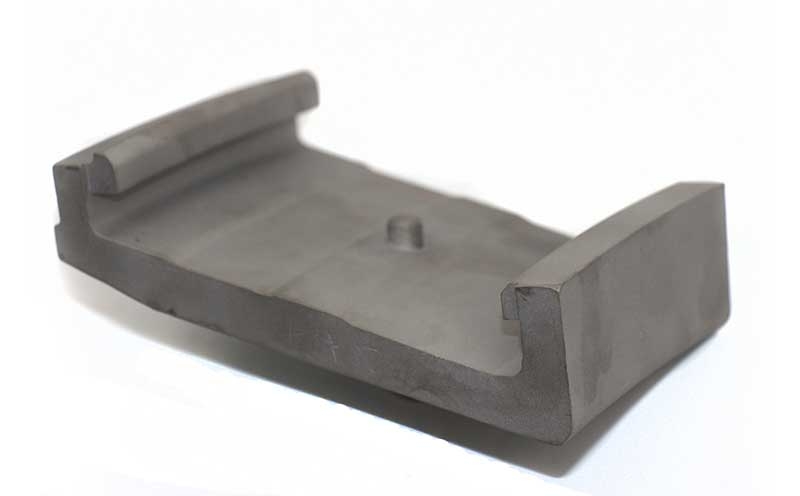

Titanium Superalloy Precision Forging Heat Sheilds: Reliable and Efficient Solutions

Introduction

Titanium superalloy heat shields offer an exceptional combination of lightweight strength, thermal resistance, and corrosion protection, ideal for aerospace and industrial thermal management systems. Neway AeroTech specializes in precision forging of titanium alloys such as Ti-6Al-4V and Ti-6Al-2Sn-4Zr-6Mo, delivering precision-forged heat shields with tight tolerances (±0.05 mm) and enhanced durability under service temperatures up to 600°C.

Employing advanced forging and heat treatment technologies, our titanium heat shields ensure superior reliability, reduced weight, and improved long-term operational efficiency for critical applications.

Core Manufacturing Challenges for Titanium Heat Shields

Forging titanium superalloys such as Ti-6Al-4V and Ti-6Al-2Sn-4Zr-6Mo involves specific challenges:

Narrow forging temperature windows (typically 850–1050°C) demanding strict thermal control.

High strain rate sensitivity, requiring careful deformation management to avoid cracking.

Achieving precise dimensional tolerances (±0.05 mm) with minimal distortion.

Controlling microstructure to balance high strength, ductility, and creep resistance.

Precision Forging Process for Titanium Heat Shields

The precision forging process for titanium heat shields involves:

Billet Heating: Uniform heating to 900–950°C ensuring homogeneous deformation behavior.

Closed-Die Forging: Application of controlled pressures and strain rates to achieve net or near-net shape components.

Isothermal Forging (for critical parts): Temperature-controlled dies reduce thermal gradients and improve microstructural uniformity.

Controlled Cooling: Slow air cooling or controlled furnace cooling to prevent residual stresses and refine grain structure.

Post-Forging Heat Treatment: Solution treatment typically at 940–970°C followed by aging to enhance mechanical properties.

Precision Machining: CNC machining to achieve final tolerances (±0.01 mm) and excellent surface finishes (Ra ≤1.6 µm).

Comparison of Manufacturing Methods for Titanium Heat Shields

Manufacturing Method | Dimensional Accuracy | Surface Finish (Ra) | Microstructure Control | Thermal Stability | Cost Efficiency |

|---|---|---|---|---|---|

Precision Forging | ±0.05 mm | ≤3.2 µm | Excellent | Superior | Medium |

Vacuum Investment Casting | ±0.1 mm | ≤3.2 µm | Good | Good | Medium |

CNC Machining (from Bar Stock) | ±0.01 mm | ≤0.8 µm | Limited | Good | High |

Manufacturing Method Selection Strategy

Selecting the optimal manufacturing method for titanium heat shields involves balancing weight, strength, precision, and cost:

Precision Forging: Preferred for aerospace-grade components requiring optimized mechanical properties, precise dimensions (±0.05 mm), and enhanced grain refinement, improving creep resistance and fatigue life by up to 30% over castings.

Vacuum Investment Casting: Suitable for complex geometries where forging is less practical. It achieves good structural performance but generally presents coarser grains and lower fatigue resistance than forging.

CNC Machining (from Bar Stock): Ideal for low-volume or high-complexity parts requiring extreme dimensional accuracy (±0.01 mm), though with increased material waste and higher costs.

Titanium Alloy Performance Matrix

Alloy Material | Max Service Temp (°C) | Tensile Strength (MPa) | Density (g/cm³) | Creep Resistance | Typical Applications |

|---|---|---|---|---|---|

400 | 930 | 4.43 | Good | Aerospace heat shields, turbine parts | |

550 | 1030 | 4.62 | Excellent | High-temperature aerospace shielding | |

480 | 870 | 4.5 | Good | Airframe thermal protection | |

540 | 965 | 4.6 | Excellent | Jet engine shielding components | |

370 | 980 | 4.68 | Good | Lightweight aerospace structures |

Alloy Selection Strategy for Titanium Heat Shields

Selection of titanium alloys depends on operational temperature, strength requirements, and design complexity:

Ti-6Al-4V: Chosen for general aerospace heat shields requiring high strength (930 MPa) and moderate thermal stability up to 400°C.

Ti-6Al-2Sn-4Zr-6Mo: Ideal for turbine shields needing excellent creep resistance and tensile strength (1030 MPa) at service temperatures up to 550°C.

Ti-5Al-2.5Sn: Suitable for airframe shielding operating at moderate temperatures (~480°C) with good weldability and strength (870 MPa).

Ti-6Al-2Sn-4Zr-2Mo: Used for jet engine shielding components demanding high thermal fatigue resistance and creep performance.

Ti-15V-3Cr-3Sn-3Al: Applied where lightweight structures are crucial, balancing high tensile strength with good thermal resistance.

Key Post-processing Techniques

Essential post-processing operations include:

Hot Isostatic Pressing (HIP): Enhances density (>99.9%) and mechanical performance by eliminating porosity.

Precision CNC Machining: Achieves final dimensional tolerances (±0.01 mm) and excellent surface finishes (Ra ≤0.8 µm).

Heat Treatment: Custom solution annealing and aging treatments optimize strength, creep, and fatigue performance.

Surface Finishing: Polishing and micro-abrasive finishing improve surface quality and thermal barrier coating adhesion.

Testing Methods and Quality Assurance

Neway AeroTech ensures every titanium heat shield meets strict aerospace quality standards through:

Coordinate Measuring Machine (CMM): Verifying dimensional precision within ±0.005 mm.

X-ray Inspection: Detecting internal voids and defects non-destructively.

Metallographic Microscopy: Evaluating grain structure uniformity and phase distribution.

Tensile Testing: Confirming tensile, yield, and elongation performance meet specifications.

Our full quality management system complies with AS9100 aerospace certification standards.

Case Study: Precision Forged Ti-6Al-2Sn-4Zr-6Mo Heat Shields

Neway AeroTech delivered forged Ti-6Al-2Sn-4Zr-6Mo heat shields for aerospace turbine systems, achieving:

Operating Temperature: Continuous use up to 550°C

Fatigue Strength: Increased by 35% after HIP and heat treatment

Dimensional Precision: ±0.03 mm consistently maintained

Certification: Fully compliant with AS9100 aerospace quality standards

FAQs

What advantages does precision forging offer for titanium heat shields?

Which titanium alloys are best suited for high-temperature shielding applications?

How do you ensure tight dimensional tolerances for forged titanium parts?

What post-processing treatments improve titanium heat shield performance?

What certifications and quality standards do your titanium heat shields meet?