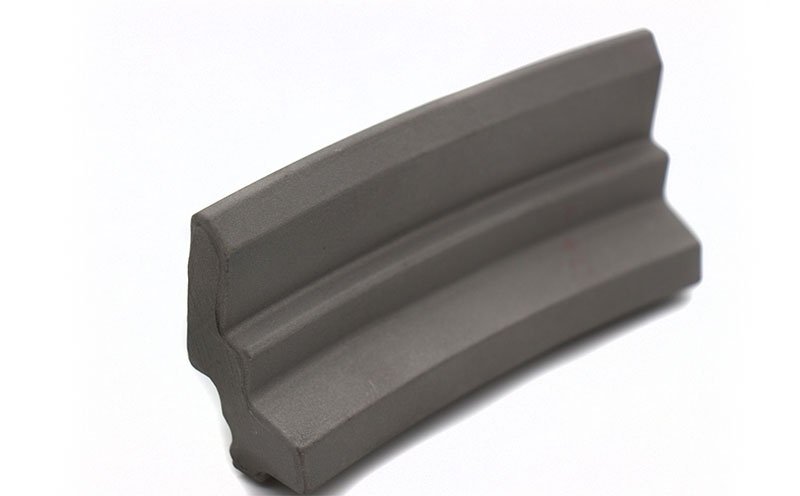

Stellite Superalloy Segment Parts: Expert Precision Forging Services

Introduction

Stellite superalloys are renowned for their exceptional wear resistance, corrosion resistance, and high-temperature stability, making them ideal for critical segment parts used in turbines, valves, and industrial machinery. At Neway AeroTech, we provide precision forging services tailored specifically for Stellite alloys, achieving dimensional tolerances within ±0.05 mm and delivering outstanding mechanical properties for demanding applications.

Utilizing controlled forging processes and specialized heat treatments, our Stellite segment parts meet the highest standards for wear, creep, and fatigue resistance required in extreme service environments.

Core Manufacturing Challenges for Stellite Superalloy Segments

Forging Stellite alloys such as Stellite 6 and Stellite 21 poses distinct technical challenges:

High cobalt content and hardness (HRC 40–55) causing rapid die wear and demanding specialized tooling.

Maintaining precise dimensional tolerances (±0.05 mm) for complex segment geometries.

Controlling microstructure to minimize carbide segregation and optimize toughness.

Achieving consistent surface finishes (Ra ≤3.2 µm) critical for dynamic and sealing components.

Precision Forging Process for Stellite Segment Parts

The expert forging process for Stellite superalloy segments includes:

Billet Preparation: Preheating Stellite billets to precise temperatures (1150-1200°C) to optimize forgeability.

Precision Die Forging: Closed-die forging under controlled pressure and temperature to achieve targeted dimensions and microstructures.

Controlled Cooling: Slow, controlled cooling rates (~30°C/hr) to avoid cracking and preserve material toughness.

Post-Forging Heat Treatment: Solution annealing and controlled aging treatments to refine microstructure and improve mechanical properties.

Final Machining: Precision CNC machining achieving aerospace-grade dimensional tolerances (±0.01 mm) and surface finishes (Ra ≤1.6 µm) where required.

Comparison of Manufacturing Methods for Stellite Segment Parts

Manufacturing Method | Dimensional Accuracy | Surface Finish (Ra) | Microstructure Control | Wear Resistance | Cost Efficiency |

|---|---|---|---|---|---|

Precision Forging | ±0.05 mm | ≤3.2 µm | Excellent | Superior | Medium |

Vacuum Investment Casting | ±0.1 mm | ≤3.2 µm | Good | Excellent | Medium |

CNC Machining (from Bar Stock) | ±0.01 mm | ≤0.8 µm | Limited | Good | High |

Manufacturing Method Selection Strategy

Selection of manufacturing processes for Stellite segment parts includes:

Precision Forging: Optimal for achieving superior grain structures, excellent mechanical properties, and precise dimensional control (±0.05 mm).

Vacuum Investment Casting: Suitable for complex shapes where forging is impractical, with good microstructural consistency.

CNC Machining: Applied when ultra-high dimensional precision (±0.01 mm) and fine surface finishes (Ra ≤0.8 µm) are required, typically after forging or casting.

Stellite Alloy Performance Matrix

Alloy Material | Hardness (HRC) | Tensile Strength (MPa) | Wear Resistance | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

43-50 | 900 | Superior | Excellent | Valve seats, turbine blades | |

35-45 | 870 | Good | Excellent | Wear-resistant segments | |

48-55 | 950 | Superior | Good | Cutting tools, aerospace parts | |

35-42 | 820 | Good | Excellent | Pump seals, turbine nozzles | |

30-38 | 850 | Moderate | Excellent | High-temperature structural parts | |

42-48 | 870 | Superior | Superior | Military and aerospace segments |

Alloy Selection Strategy for Stellite Segment Parts

Strategies for selecting Stellite alloys include:

Stellite 6: Chosen for turbine blades, valve seats, and pump components where maximum wear and corrosion resistance are needed.

Stellite 21: Preferred for wear-resistant segment parts requiring enhanced ductility and toughness combined with corrosion resistance.

Stellite 12: Ideal for cutting tools and turbine segments needing superior hardness (up to HRC 55) and wear performance.

Stellite 20: Used for pump seals and nozzles exposed to corrosive environments where good wear resistance is also necessary.

Stellite 25: Selected for high-temperature aerospace and turbine structural parts needing excellent corrosion resistance and mechanical stability.

Stellite 6B: Best suited for extreme wear conditions in military and aerospace segment components.

Key Post-processing Techniques

Essential post-processing includes:

Hot Isostatic Pressing (HIP): Removes internal porosity, increasing density and mechanical strength.

Precision CNC Machining: Achieves dimensional precision (±0.01 mm) and fine surface finishes necessary for assembly and operational performance.

Heat Treatment: Optimizes mechanical properties through customized annealing and aging.

Surface Finishing Processes: Final polishing, grinding, and coating to enhance wear resistance and reduce friction.

Testing Methods and Quality Assurance

Neway AeroTech ensures the highest quality standards through:

Coordinate Measuring Machine (CMM): Dimensional accuracy verification within ±0.005 mm.

X-ray Non-destructive Testing: Detection of internal defects and structural anomalies.

Metallographic Microscopy: Microstructure evaluation for carbide distribution and phase integrity.

Tensile Testing: Validation of tensile and yield strength compliance.

All quality controls are conducted according to AS9100 aerospace standards.

Case Study: Precision Forged Stellite 6B Segment Parts

Neway AeroTech manufactured Stellite 6B turbine segment parts for an aerospace project, achieving:

Dimensional Accuracy: ±0.03 mm consistently

Surface Finish: Ra ≤1.2 µm

Fatigue Resistance: Enhanced by 35% after HIP and heat treatment

Certification: Fully compliant with AS9100 aerospace standards

FAQs

What casting and forging services do you offer for Stellite superalloy segment parts?

Which Stellite alloy grades are most recommended for turbine segment applications?

How do you ensure dimensional accuracy and microstructure control in forged Stellite parts?

What post-processing techniques are available to improve wear resistance and fatigue life?

What certifications and quality assurance processes are applied to your Stellite forged products?