High-Temperature Alloys Sanitary Components Casting Company

Introduction to High-Temperature Alloy Sanitary Components Casting

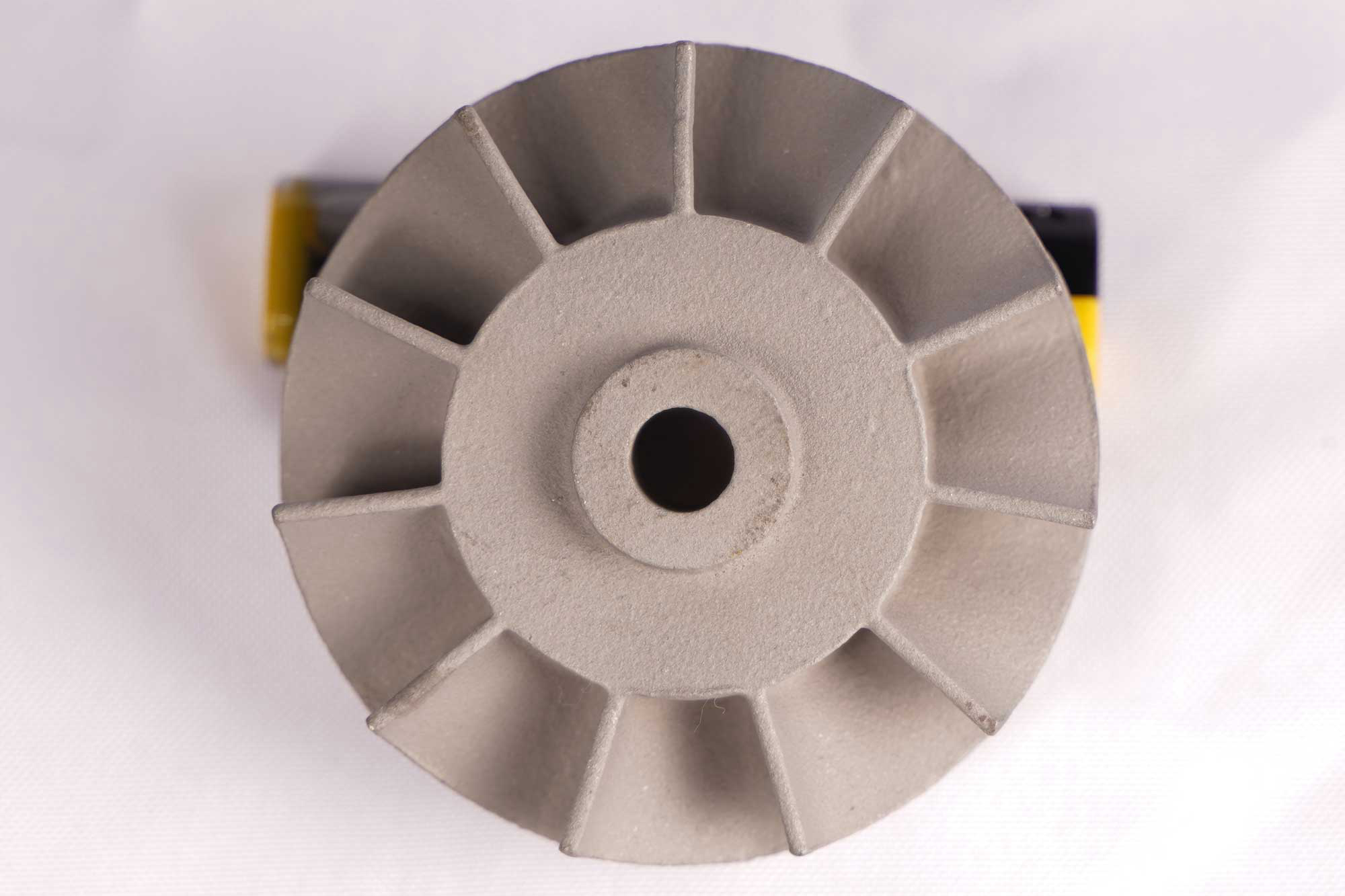

In the pharmaceutical, chemical, and food industries, sanitary components require exceptional corrosion resistance, thermal stability, and hygienic compliance. Neway AeroTech specializes in vacuum investment casting of high-temperature alloy sanitary components, utilizing advanced alloys such as Hastelloy C-276, Monel K500, and Inconel 625. Our precise casting technology ensures superior corrosion resistance, hygienic surface finish, and precise dimensional tolerances essential for critical applications.

Our advanced manufacturing expertise positions us as a leading supplier of custom-engineered sanitary components for demanding high-temperature applications.

Key Challenges in Sanitary Component Casting

Casting sanitary components from high-temperature alloys presents specific challenges:

Corrosion and Chemical Resistance: Ensuring stable microstructures and uniform alloy composition to resist aggressive media exposure.

Dimensional Accuracy: Meeting tight dimensional tolerances (±0.1 mm) crucial for sanitary fittings and sealing.

Surface Quality: Maintaining smooth, defect-free finishes (Ra 0.8–3.2 µm) for optimal hygiene and reduced microbial growth.

High-Temperature Stability: Achieving consistent performance and integrity at elevated temperatures (up to 1200°C).

Detailed Casting Process for High-Temperature Sanitary Components

Wax Pattern Preparation

Highly accurate wax patterns produced within ±0.05 mm dimensional precision, enabling consistent and repeatable component geometries.

Ceramic Shell Formation

Robust ceramic molds created via multiple slurry-dipping layers, forming shells typically 8–12 mm thick, suitable for molten alloy temperatures above 1300°C.

Vacuum Melting and Precision Casting

Vacuum induction melting performed at ultra-low pressures (<0.1 Pa) to ensure exceptional alloy purity and minimal oxidation.

Controlled casting ensures defect-free components with uniform grain structures and excellent corrosion-resistant properties.

Finishing and Inspection

Ceramic shells removed carefully via chemical dissolution and mechanical methods.

Precision CNC machining refines final dimensions (±0.1 mm) and surface finishes (Ra 0.8–3.2 µm).

Rigorous inspection, including NDT, guarantees compliance with stringent hygienic and industry standards.

Comparison of Sanitary Component Manufacturing Methods

Process | Dimensional Accuracy | Surface Finish | Corrosion Resistance | Production Efficiency |

|---|---|---|---|---|

Vacuum Investment Casting | ±0.10 mm | Ra 0.8–3.2 µm | Excellent | High |

CNC Machining | ±0.005 mm | Ra 0.4–0.8 µm | Good | Moderate |

Precision Forging | ±0.2 mm | Ra 6.3–12.5 µm | Very Good | High |

Selective Laser Melting (SLM) | ±0.10 mm | Ra 6.3–12.5 µm | Excellent | Moderate |

Manufacturing Process Selection Strategy

Vacuum Investment Casting: Preferred for sanitary components requiring superior corrosion resistance, precise dimensional accuracy (±0.10 mm), and excellent surface finish.

CNC Machining: Essential for critical sealing surfaces and intricate internal geometries requiring ultra-high precision and surface smoothness.

Precision Forging: Ideal for robust structural components needing high mechanical strength and acceptable corrosion resistance.

Selective Laser Melting (SLM): Excellent for rapid prototyping and complex geometry production with internal channels.

High-Temperature Alloy Material Performance Matrix

Alloy | Tensile Strength | Yield Strength | Corrosion Resistance | Max Temp | Typical Sanitary Applications |

|---|---|---|---|---|---|

750 MPa | 350 MPa | Excellent (Chloride, acids) | 1038°C | Corrosive chemical sanitary valves | |

965 MPa | 690 MPa | Superior (Acid, Alkali, Chloride) | 600°C | High-pressure sanitary fittings | |

880 MPa | 460 MPa | Excellent (Oxidation, Acids) | 982°C | High-temp pharmaceutical valves | |

1375 MPa | 1100 MPa | Excellent (High-temp, corrosion) | 700°C | Extreme conditions sanitary valves | |

550 MPa | 240 MPa | Excellent (Marine, Acids) | 538°C | General chemical processing valves | |

760 MPa | 350 MPa | Superior (Hydrochloric Acid) | 1000°C | Sanitary fittings for aggressive acids |

Alloy Selection Strategy

Hastelloy C-276: Optimal choice for valves handling severe chloride-rich chemicals and highly aggressive acids.

Monel K500: Recommended for high-pressure sanitary fittings requiring high mechanical strength and superior corrosion resistance.

Inconel 625: Suitable for pharmaceutical and food-processing applications at elevated temperatures requiring excellent oxidation resistance.

Inconel 718: Ideal for critical sanitary components exposed to extreme conditions, offering exceptional tensile strength and corrosion stability.

Monel 400: General-purpose alloy for moderately corrosive environments, widely used in food and chemical industries.

Hastelloy B-2: Preferred for sanitary components handling concentrated hydrochloric acid, providing robust resistance and reliability.

Key Post-processing Technologies

Precision CNC Machining: Ensures dimensional accuracy (±0.005 mm) and surface finishes critical for sanitary applications.

Electropolishing and Passivation: Enhances surface quality, corrosion resistance, and hygiene.

Hot Isostatic Pressing (HIP): Removes internal porosity, improving component integrity.

Non-destructive Testing (NDT): Verifies internal and surface quality, ensuring compliance with sanitary standards.

Industry Case Study: High-Temp Alloy Components for Pharmaceutical Sanitary Applications

Neway AeroTech recently supplied custom-cast Inconel 625 sanitary valve components for a major pharmaceutical firm. Leveraging advanced vacuum investment casting, we achieved precise tolerances (±0.10 mm), superior surface finishes (Ra 0.8–3.2 µm), and exceptional corrosion resistance, significantly improving reliability and compliance in sterile environments.

Our expertise and proven results underscore our reputation in high-temperature sanitary alloy casting.

FAQs

What lead times do you provide for high-temperature sanitary alloy castings?

Are your sanitary components compliant with FDA or equivalent regulatory standards?

Can you handle small-batch or customized sanitary alloy component orders?

What quality control procedures ensure the consistency of your sanitary castings?

Do you provide material selection advice for specific chemical and pharmaceutical sanitary applications?