PWA 1484 Single Crystal Casting Marine Propulsion Systems Fabricator

Introduction

PWA 1484 is a second-generation nickel-based single-crystal (SX) superalloy designed for exceptional creep resistance, oxidation resistance, and structural integrity in high-temperature environments. Originally developed for aerospace turbines, its superior performance also makes it ideal for marine propulsion systems operating under extreme thermal and mechanical loads. As a specialized single crystal casting fabricator, we produce PWA 1484 propulsion components with [001] orientation, tight dimensional tolerances (±0.05 mm), and porosity under 1%.

Our castings are tailored for naval gas turbines, turbochargers, and exhaust components where long-term durability and creep resistance are critical.

Core Technology: Single Crystal Casting of PWA 1484

We use vacuum directional solidification to produce PWA 1484 marine components with single-crystal [001] orientation. The alloy is vacuum melted and cast at ~1460°C into ceramic shell molds preheated to ~1100°C. Molds are withdrawn at 1–3 mm/min in a Bridgman furnace to produce single-crystal structures, eliminating grain boundaries and enhancing creep strength, thermal fatigue life, and oxidation resistance.

Material Characteristics of PWA 1484 Alloy

PWA 1484 is a γ′-strengthened SX nickel-based superalloy with excellent high-temperature mechanical and chemical stability. It is widely used in first-stage turbine blades and structural hot-section parts. Key properties include:

Property | Value |

|---|---|

Density | 8.9 g/cm³ |

Ultimate Tensile Strength (at 1093°C) | ≥1140 MPa |

Creep Rupture Strength (1000h @ 1093°C) | ≥200 MPa |

Operating Temperature Limit | Up to 1200°C |

Oxidation Resistance | Excellent |

Grain Structure | Single Crystal [001] |

These properties enable PWA 1484 components to maintain dimensional and mechanical integrity in marine turbines exposed to high thermal gradients and corrosive gas flows.

Case Study: Marine Gas Turbine Blade Production

Project Background

A naval propulsion systems contractor required first-stage blades and nozzle components for a high-performance marine gas turbine used in a frigate-class vessel. The blades needed to withstand 1150°C exhaust conditions and salt-laden combustion gases. PWA 1484 was selected for its long-cycle durability and high creep rupture strength. We delivered single-crystal, vacuum-cast components with HIP treatment, CNC finishing, and EB-PVD thermal barrier coatings.

Typical Marine Propulsion Applications

Naval Gas Turbine Blades (e.g., LM2500 Marine, WR-21): PWA 1484 SX blades withstand extreme pressure and temperature in shipboard gas turbines with long mission profiles.

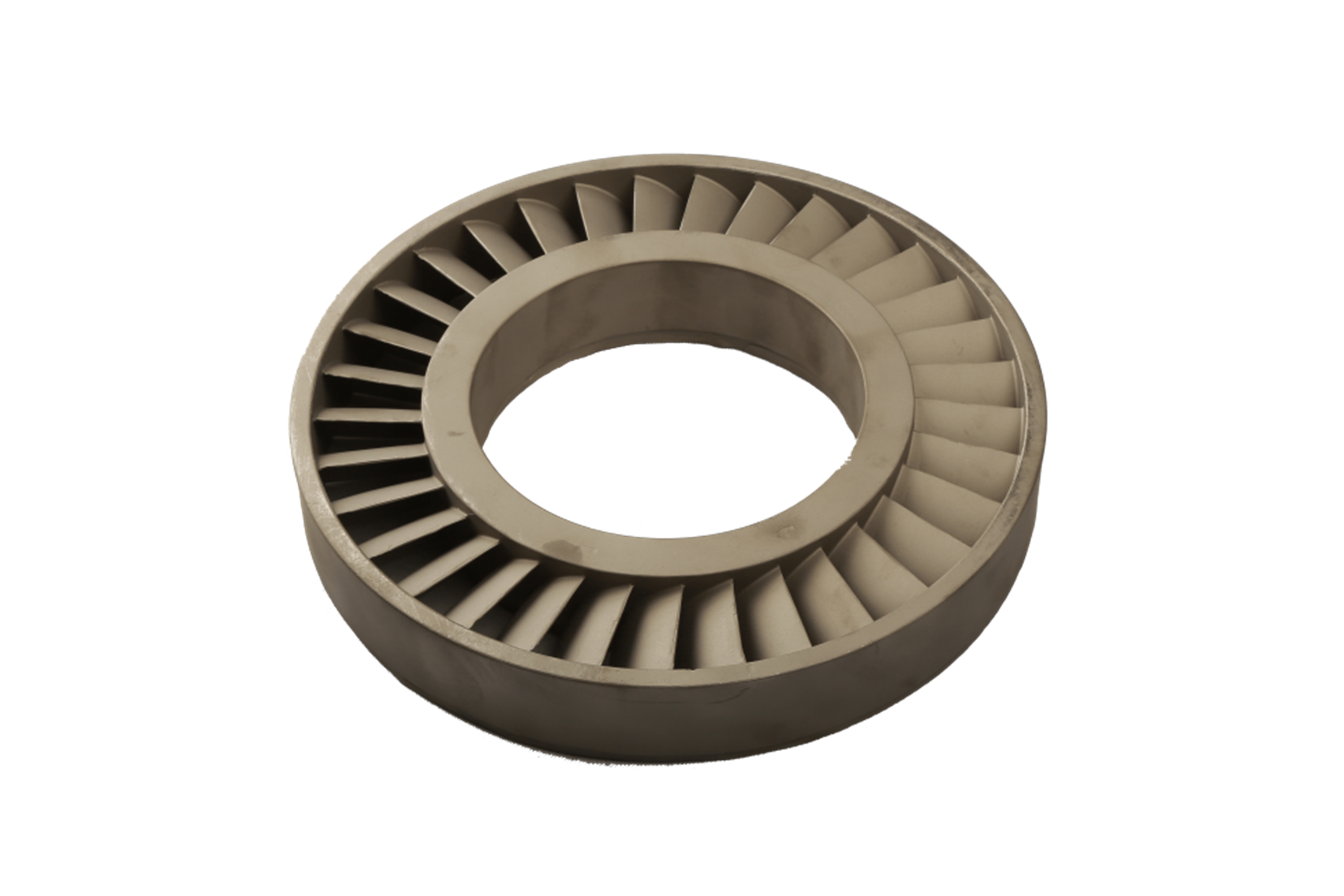

Exhaust Nozzle Guide Vanes: Single-crystal vanes used in marine turbine nozzles requiring low thermal expansion, oxidation resistance, and dimensional precision.

High-Temperature Transition Ducts: Fixed SX castings exposed to exhaust heat and high-velocity flow between the combustor and turbine inlet stages.

Turbocharger Rotor Blades (Marine Diesel Hybrid Systems): PWA 1484 blades in advanced naval auxiliary engines with extreme thermal cycling and oxidation exposure.

These parts operate in salt-rich, high-cycle environments, requiring the high reliability and thermal stability that PWA 1484 provides.

Manufacturing Solutions for PWA 1484 Marine Components

Casting Process Wax assemblies are invested into ceramic molds and vacuum cast at ~1460°C. Mold withdrawal is precisely controlled to produce single-crystal [001] orientation. Cooling profiles are optimized to prevent stray grain formation and internal defects.

Post-processing Hot Isostatic Pressing (HIP) at ~1190°C and 100 MPa improves density and eliminates porosity. Heat treatment sequences optimize γ′ precipitation for maximum creep and fatigue resistance.

Post Machining CNC machining finalizes precision features including root fits, mounting surfaces, and trailing edges. EDM is used for tight airfoil tolerances. Deep hole drilling enables cooling channel integration.

Surface Treatment Thermal barrier coatings (TBC) are applied via EB-PVD or APS to protect surfaces from thermal oxidation. Aluminide coatings may be used for added salt corrosion protection in marine environments.

Testing and Inspection All components are subjected to X-ray NDT, CMM dimensional validation, elevated-temperature tensile and creep testing, and metallographic analysis to confirm SX structure, γ′ distribution, and coating adhesion.

Core Manufacturing Challenges

Maintaining single-crystal [001] orientation over complex, multi-axis blade geometries.

Preventing stray grain and recrystallization during solidification and heat treatment.

Ensuring oxidation resistance and fatigue durability in salt-rich, high-temperature exhaust flows.

Results and Verification

SX integrity verified by Laue diffraction and SEM microstructure imaging.

Dimensional accuracy within ±0.05 mm confirmed by 3D CMM scanning.

Creep rupture strength ≥200 MPa at 1093°C validated through 1000-hour testing.

Surface oxidation resistance maintained after 1000 marine salt fog/thermal cycles.

FAQs

Why is PWA 1484 suitable for marine gas turbine casting applications?

How do you control single-crystal orientation during casting?

Can PWA 1484 parts be customized for naval propulsion layouts?

What coatings are used to enhance oxidation and salt corrosion resistance?

What inspection methods confirm the structural quality of single-crystal marine components?