Plasma Thermal Barrier Coating for Super Alloy Aviation Blades

Introduction

In modern jet engines, turbine blades operate in extreme environments where surface temperatures can exceed 1100°C. Even advanced nickel-based superalloys, such as Rene 80, CMSX-4, and PWA 1484, require protection from oxidation, thermal fatigue, and hot corrosion. Plasma-applied Thermal Barrier Coatings (TBCs) provide a critical insulating layer on these superalloy blades, extending their life and improving overall engine efficiency.

At our facility, we specialize in applying plasma-sprayed TBCs to aerospace-grade turbine blades, ensuring coating adhesion, thickness control, and thermal insulation performance compliant with aerospace and OEM specifications.

What Is Plasma-Applied Thermal Barrier Coating?

Plasma-sprayed TBC is a multi-layer ceramic coating system applied using Atmospheric Plasma Spray (APS) or Vacuum Plasma Spray (VPS). It typically consists of:

Bond Coat (e.g., MCrAlY or PtAl): Promotes adhesion and protects the substrate from oxidation and hot corrosion.

Top Coat (usually 7–8 wt% Yttria-Stabilized Zirconia – YSZ): Provides low thermal conductivity and insulates the underlying superalloy from extreme heat.

During plasma spraying, molten particles are propelled onto the blade surface, forming a layered microstructure that resists spallation and thermal stress.

Key Benefits for Superalloy Aviation Blades

Benefit | Description |

|---|---|

Thermal Insulation | Reduces metal surface temperature by 100–200°C, protecting the substrate. |

Oxidation Resistance | Limits diffusion of oxygen and prevents surface scaling at high temperatures. |

Creep & Fatigue Life | Lowers thermal stress, improving blade fatigue resistance and time to failure. |

Fuel Efficiency | Enables higher turbine inlet temperatures (TIT), increasing engine efficiency. |

Maintenance Reduction | Extends overhaul intervals and reduces blade replacement rates. |

Superalloy Substrates for TBC Application

We apply plasma TBCs to a wide range of single-crystal and directionally solidified superalloys, including:

CMSX-4 – for first-stage HPT blades in both commercial and military engines.

PWA 1484 – used in hot-section turbine blades and vanes.

Rene 80 – commonly applied to nozzle guide vanes and industrial turbine blades.

Rene N5 and N6 – used in single-crystal blades where phase stability and thermal protection are essential.

Each alloy requires precise surface preparation, bond coat selection, and thermal cycling validation.

Coating Process Overview

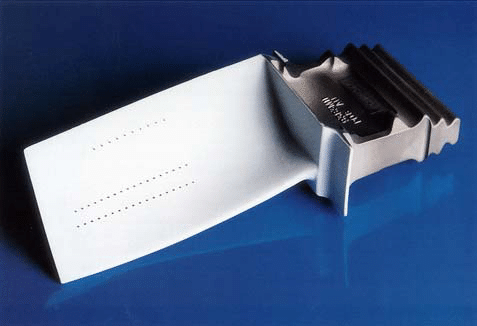

1. Surface Preparation

Blades are degreased, grit-blasted, and cleaned to remove oxidation and promote bond coat adhesion.

2. Bond Coat Application

An MCrAlY (NiCoCrAlY or CoNiCrAlY) layer is applied via HVOF or plasma spray. It forms the oxidation-resistant interface between the substrate and ceramic.

3. Top Coat Application (YSZ)

The 7–8% YSZ layer is applied via APS, achieving a typical thickness of 150–300 μm with controlled porosity for thermal strain relief.

4. Post-Coating Processing

Optional heat treatment or sealing processes may be used to improve spallation resistance or match OEM specifications.

Quality Assurance and Testing

We perform comprehensive inspections and qualification testing to ensure coating performance and longevity, including:

Coating Thickness Measurement (±10 μm)

Adhesion Testing (ASTM C633)

Thermal Shock & Cycling Tests (up to 1100°C)

Microstructure & Porosity Analysis (SEM, image analysis)

Bond Coat–Top Coat Interface Inspection

All coatings comply with aerospace coating specifications such as GE C50TF26, Pratt & Whitney PWA 36945, and Rolls-Royce RPS 661.

Results and Performance

Metal surface temperature reduction: Up to 200°C

Thermal fatigue cycles survived: >1000 at 1150°C

Spallation resistance: >95% coverage after 500-hour thermal cycling

Bond strength: ≥30 MPa (ASTM C633)

These results ensure high confidence in TBC integrity during long operational cycles.

FAQs

What alloys are compatible with plasma-sprayed TBCs for jet engine blades?

How thick should the ceramic top coat be for turbine blade applications?

What thermal cycling limits can plasma TBCs handle?

Can TBCs be reapplied after refurbishment of superalloy blades?

What testing methods verify coating adhesion and thermal performance?