Plasma Thermal Barrier Coating for High-Temperature Alloy Turbine Vanes

Introduction

Turbine vanes operate in the hottest sections of jet engines and industrial gas turbines, enduring combustion gases exceeding 1100°C. Even with advanced high-temperature alloys such as Rene 80, Rene N5, and PWA 1484, the base metal requires additional thermal protection to avoid oxidation, creep, and premature failure. Plasma-applied Thermal Barrier Coatings (TBCs) provide a critical insulating layer that significantly reduces metal surface temperature and extends component life.

Our facility specializes in applying high-performance TBC systems to turbine vanes used in aerospace and power generation, ensuring coating thickness uniformity, thermal shock resistance, and long-term oxidation protection.

Why TBC Is Essential for Turbine Vanes

High-temperature alloy turbine vanes are subject to:

Hot gas impingement at 1100–1200°C

Oxidation and corrosive species in combustion flow

Thermal fatigue and cycling during engine startup/shutdown

Creep and surface degradation from prolonged exposure

Plasma-sprayed TBCs reduce surface temperature by 100–200°C, improving creep life, minimizing oxidation, and enabling engines to operate at higher turbine inlet temperatures (TIT) with improved efficiency.

TBC System Structure

Layer | Material | Function |

|---|---|---|

Bond Coat | MCrAlY or PtAl | Provides oxidation protection and promotes adhesion |

Top Coat | 7–8 wt% Yttria-Stabilized Zirconia (YSZ) | Acts as a thermal insulator with strain tolerance |

The layered structure is engineered to match the thermal expansion of the substrate, preventing spallation during thermal cycling.

Compatible High-Temperature Alloys

We apply TBC systems to a wide range of directionally solidified (DS) and single-crystal (SX) turbine vane materials:

Rene 80 – Used in HPT vanes and nozzles in aero and land-based turbines

PWA 1484 – High-thrust engine turbine vanes

Rene N5/N6 – Jet engine and power turbine vanes operating under long-cycle exposure

CMSX-4 – SX vanes in GE, Rolls-Royce, and Pratt & Whitney hot sections

Each alloy is prepped for coating using proprietary grit blasting and bond coat application procedures to ensure maximum adhesion and life.

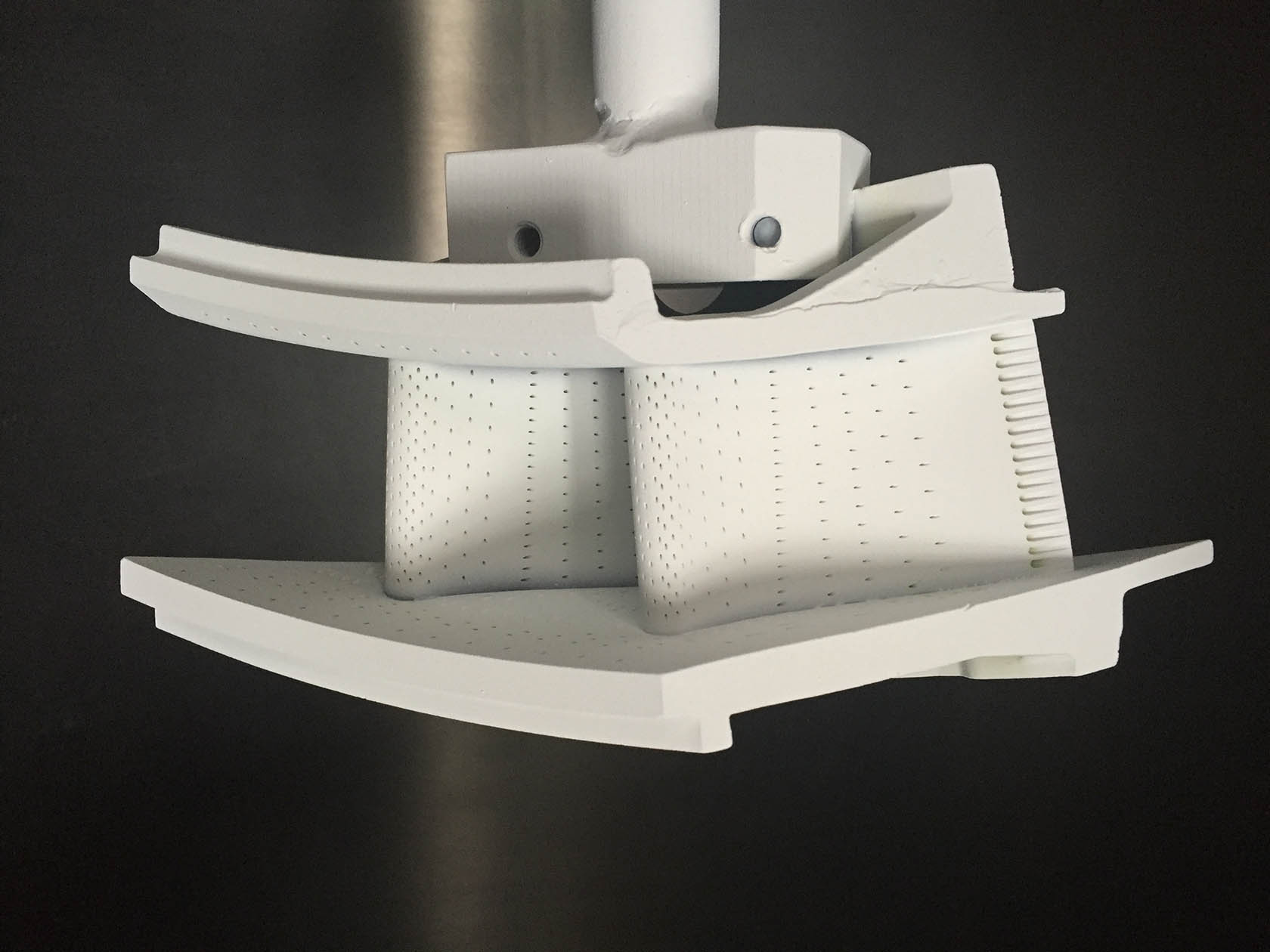

Plasma Spray Process Overview

1. Surface Preparation

Degreasing, grit blasting, and cleaning remove oxide layers and prepare the vane for optimal bond coat adhesion.

2. Bond Coat Application

A MCrAlY bond coat (typically NiCoCrAlY or CoNiCrAlY) is applied via HVOF or plasma spray, forming a thermally grown oxide (TGO) interface for ceramic adhesion.

3. Top Coat Application

The YSZ ceramic is deposited using Atmospheric Plasma Spray (APS) or Electron Beam Physical Vapor Deposition (EB-PVD), depending on vane geometry and OEM requirements.

4. Post-Processing

Thermal conditioning or sealing processes are applied to enhance spallation resistance and ensure coating integrity over long service cycles.

Benefits of Plasma TBC for Turbine Vanes

Benefit | Description |

|---|---|

Thermal Protection | Lowers metal temperature by up to 200°C |

Creep Life Extension | Reduces thermal stress and delays deformation |

Oxidation Resistance | Prevents surface scale and corrosion |

Fatigue Resistance | Accommodates thermal expansion, reducing crack initiation |

Efficiency Boost | Enables higher TIT for better engine efficiency and lower fuel consumption |

Quality Control and Testing

All coatings are applied and verified in accordance with aerospace and energy-sector OEM specifications such as:

GE C50TF26

PWA 36945

Rolls-Royce RPS 661

Siemens SPPM-140

Our coating validation includes:

Thickness measurement (±10 μm control)

Adhesion testing (ASTM C633)

Thermal cycling (>1000 cycles at 1100–1200°C)

SEM cross-section analysis

TGO growth and porosity evaluation

Application Examples

F135 HPT Vanes (PWA 1484): EB-PVD TBC for enhanced fatigue life in military afterburning engines

GE Frame 9E Turbine Nozzles (Rene 80): APS TBC applied to extend life in base-load power plants

Trent 1000 CMSX-4 Vanes: Multi-layer EB-PVD TBC for corrosion and thermal protection in high-bypass turbofans

LM6000 Industrial Gas Vanes (Rene N5): APS-applied TBC to support hot gas path components in long-cycle turbine operation

FAQs

What is the recommended TBC thickness for turbine vanes?

How does EB-PVD compare to APS for vane coatings?

Can vanes be re-coated after in-service exposure?

What is the typical thermal cycling life of a plasma TBC system?

What standards do your coatings meet for OEM compliance?