High-Temperature Alloy Casting Turbine Parts Treatment Factory

Thermal Processing for High-Strength Equiaxed Turbine Alloys

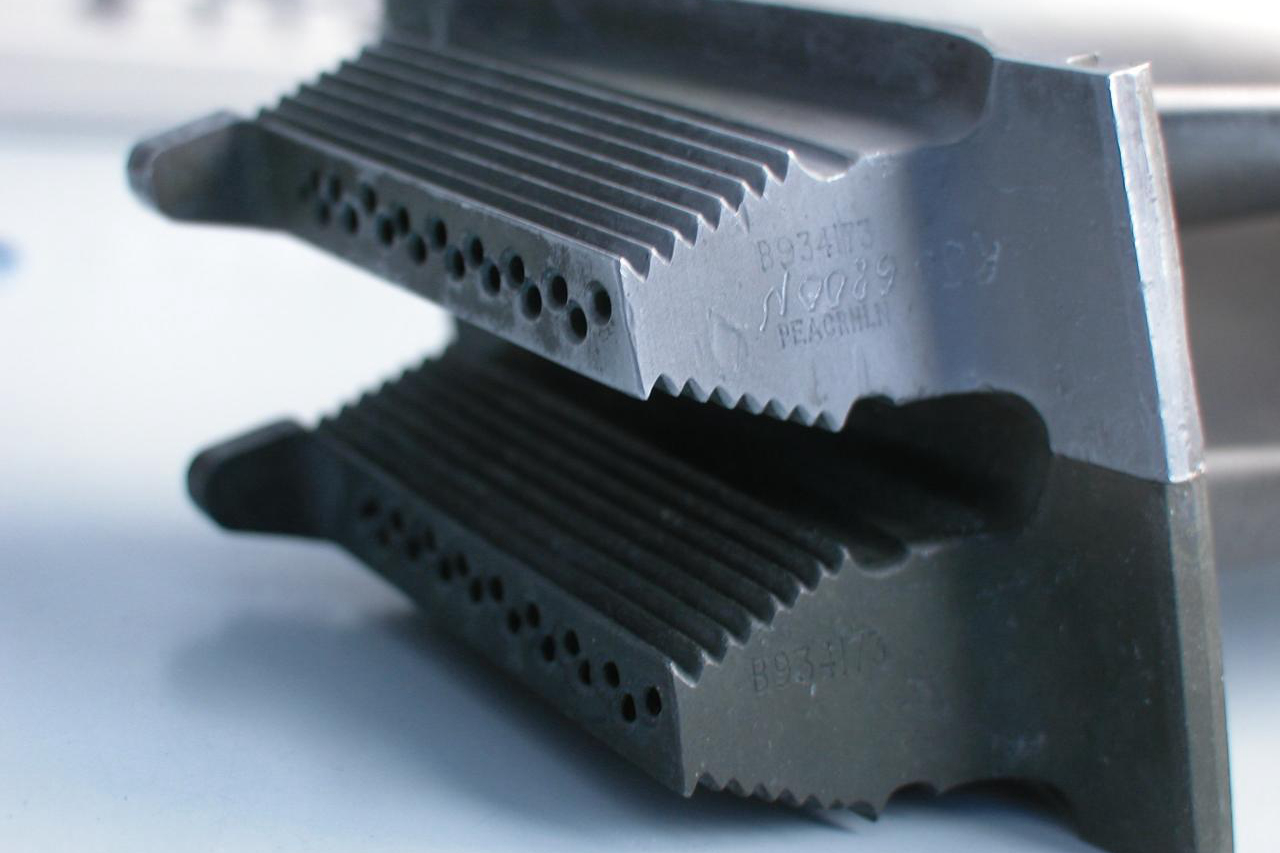

Equiaxed crystal castings made from nickel-based superalloys are widely used in turbine blades, vanes, and combustion components across aerospace and energy sectors. To unlock their full mechanical and microstructural performance, these castings require precision-controlled heat treatment cycles for grain refinement, stress relief, and phase transformation stabilization.

Neway AeroTech is a certified heat treatment supplier for equiaxed crystal superalloy castings such as Inconel 713C, Rene 77, and Hastelloy X. Our thermal processing solutions ensure structural integrity, dimensional stability, and fatigue resistance in both OEM and repair-grade components.

Core Heat Treatment Capabilities for Equiaxed Castings

Our thermal cycles are engineered to meet turbine OEM and aerospace standards for grain control, residual stress management, and mechanical property optimization.

Solution treatment for gamma prime phase uniformity

Aging treatment to increase yield strength and creep resistance

Stress-relief annealing post-casting or machining to eliminate internal residual stress

Controlled ramp rates and inert atmosphere for oxidation-sensitive parts

All heat treatments conform to AMS 2774, AMS 5662/3, and customer-specific turbine alloy protocols.

Superalloys Commonly Heat Treated

Alloy | Max Service Temp (°C) | Heat Treatment Purpose | Application |

|---|---|---|---|

950 | Stress relief + aging | Nozzle guide vanes | |

1040 | Solution + aging | Turbine blades, vane rings | |

1175 | Grain stabilization | Combustor hardware | |

920 | Aging hardening | Vane segments, valve guides |

These alloys benefit from phase strengthening and microstructure densification via tightly controlled temperature-time profiles.

Case Study: Heat Treatment of Equiaxed Rene 77 Vane Ring Segments

Project Background

An aerospace customer submitted a batch of equiaxed Rene 77 cast vane segments requiring full-cycle thermal processing. The cycle included solution treatment at 1160°C, aging at 845°C for 24 hours, and final stress relief at 870°C. All parts met OEM microstructure and hardness requirements.

Typical Heat Treated Component Models and Applications

Component | Alloy | Process | Industry |

|---|---|---|---|

Nozzle Segment | Inconel 713C | Aging + stress relief | |

Vane Ring | Rene 77 | Solution + aging | |

Combustor Liner | Hastelloy X | Annealing + stress relief | |

Turbine Shroud | Nimonic 90 | Aging hardening |

All components are validated for grain size, phase structure, and hardness consistency post-treatment.

Heat Treatment Challenges for Equiaxed Superalloy Castings

Uniform temperature distribution is critical to prevent grain boundary liquation and deformation

Controlled ramp rates ≤ 10°C/min reduce thermal shock and structural distortion

Atmospheric control (vacuum or argon) needed to suppress oxidation on critical surfaces

Repeatability of microstructure across thick and thin cast cross-sections

Residual stress relief required before CNC finishing or coating application

Certified Heat Treatment Solutions

Multi-zone furnaces with ±2°C thermal uniformity across load volume

Vacuum or argon purged chambers for reactive alloys like Rene and Hastelloy

Cycle programming with real-time data logging for full traceability

**Integrated post-treatment cleaning and passivation

HIP available as a combined service to eliminate porosity

Results and Verification

Thermal Process Execution

All cycles followed material-specific solution and aging protocols with soak times validated by thermocouple mapping. Castings were fixtured to minimize deformation during high-temperature exposure.

Post-Treatment Finishing

After treatment, parts underwent CNC machining or EDM. Surfaces were cleaned and passivated per AMS2700 for oxidation protection.

Inspection and Testing

SEM analysis confirmed phase formation and grain refinement. Hardness testing validated mechanical targets. X-ray inspection confirmed structural soundness post-treatment.

FAQs

What heat treatment cycles are used for equiaxed turbine components?

Can Inconel and Rene alloys be treated together in one furnace batch?

How is oxidation prevented during high-temperature solution treatment?

What inspection methods verify phase transformation and hardness?

Do you offer HIP and CNC machining after heat treatment?