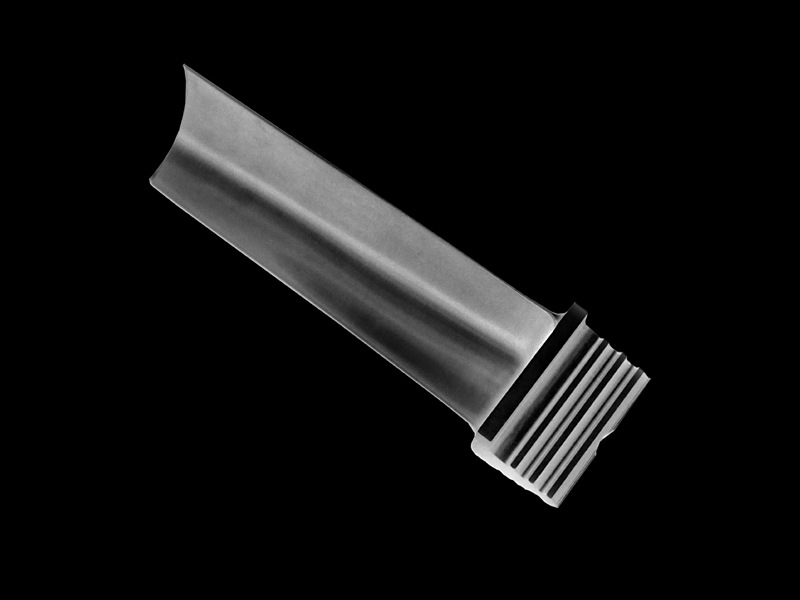

CMSX-10 Vacuum Investment Casting Jet Engine Blades

Introduction

CMSX-10 vacuum investment casting is one of the most advanced solutions for manufacturing jet engine blades designed for the highest temperature turbine stages. At Neway AeroTech, we specialize in producing CMSX-10 single-crystal blades for aerospace propulsion and military turbine engines. These blades withstand operating temperatures exceeding 1150°C, offering superior creep resistance, oxidation protection, and thermal fatigue performance.

Our precision vacuum investment casting process ensures directional solidification and single-crystal growth in the <001> direction, eliminating grain boundaries and maximizing long-term reliability in critical high-pressure turbine sections.

Core Technology of CMSX-10 Blade Casting

Wax Pattern Creation: High-precision blade profiles are molded in wax to replicate complex airfoil and root geometries within ±0.05 mm tolerance.

Ceramic Shell Formation: Shell molds built using 8–10 ceramic layers to ensure mechanical strength during high-temperature casting.

Vacuum Melting and Pouring: CMSX-10 alloy is melted and poured under vacuum (<10⁻³ torr) to prevent oxidation and ensure alloy purity.

Directional Solidification (Bridgman Process): Blade cast with withdrawal speed of 3–6 mm/min and thermal gradient >10°C/mm to promote <001> single crystal growth.

Heat Treatment: Solution and aging treatment at 1280–1320°C solution and 1080–870°C aging enhances γ′ distribution and creep resistance.

CNC Finishing: Fir-tree roots, cooling slots, and shroud features are machined to ±0.02 mm using multi-axis CNC machining.

Optional Surface Coating: Thermal Barrier Coatings (TBC) applied to increase oxidation resistance and reduce metal temperatures in hot gas environments.

Material Properties of CMSX-10 for Jet Engine Blades

Property | Value |

|---|---|

Max Operating Temperature | 1170–1200°C |

Ultimate Tensile Strength | ≥1240 MPa |

Creep Rupture Life | >1000 hrs at 1100°C / 137 MPa |

Oxidation Resistance | Excellent in jet fuel combustion gases |

Grain Structure | Single Crystal <001> |

γ′ Volume Fraction | ~70% |

Machinability | Low; requires advanced tooling |

Case Study: CMSX-10 Blade for Advanced Military Jet Engine

Project Background

A defense jet engine program required high-performance HPT blades for operation at >1150°C with >25,000 thermal cycles. CMSX-10 was selected for its high γ′ content, thermal fatigue strength, and structural integrity under high rotational load.

Typical Applications of CMSX-10 Jet Engine Blades

F135 HPT Blades: Single-crystal CMSX-10 blades used in the F-35 Lightning II engine, providing long life in the most thermally stressed zones.

Eurofighter EJ200 Blades: CMSX-10 applied in high-performance fighter engines requiring creep resistance and dimensional stability under afterburner conditions.

GE XA100/XA101 Programs: CMSX-10 blades under evaluation for next-generation adaptive cycle engines to meet extreme thermal and thrust demands.

Advanced Auxiliary Power Units (APUs): Used in high-efficiency compact turbines where thermal fatigue and oxidation are key limiting factors.

Manufacturing Process Overview

Wax Assembly: Wax blades arranged in precision clusters with controlled blade alignment and root orientation.

Shell Building and Drying: 8–10 ceramic layers applied and cured under cleanroom humidity controls to avoid shell cracking.

Vacuum Casting: CMSX-10 poured under vacuum with precise withdrawal control to ensure single crystal growth in each blade.

Shell Removal and Cleaning: Ceramic removed via blasting; surfaces acid-cleaned and inspected for casting defects.

Heat Treatment: Two-stage aging after high-temperature solutioning develops uniform γ′ precipitation for creep strength.

Machining and Finishing: Platform faces, root interfaces, and cooling features finished with ±0.02 mm accuracy using advanced CNC systems.

Inspection and Testing: X-ray for porosity, CMM inspection for dimensions, and EBSD for grain orientation validation.

Results and Performance Validation

Creep Resistance: Surpassed 1000-hour creep rupture tests at 1100°C with <1% elongation under 137 MPa.

Grain Orientation Accuracy: EBSD verified <001> alignment within 10° for all production blades.

Fatigue Life: Passed 25,000+ thermal cycles from 300°C to 1150°C without cracking or grain boundary separation.

Oxidation Performance: TBC-coated blades exhibited no spallation after 1000-hour cyclic exposure at 1170°C.

Dimensional Control: All blade dimensions confirmed within ±0.02 mm; platform-to-platform uniformity achieved across full batch.

FAQs

What makes CMSX-10 superior to CMSX-4 for jet engine blades?

What is the advantage of single crystal blades over equiaxed or directionally solidified blades?

What are the key post-processing steps for CMSX-10 blade casting?

How is crystal orientation verified in single crystal blades?

Can Neway AeroTech customize CMSX-10 blade designs for different turbine stages?